2024/09/22

Foam Production Methods

Table of contents Foam Production Methods There are two basic methods for commercial foam production: spray and pour. The spray method is generally limited to rigid foams, while the pour method is used for all types of foams. Pour-in-Place (Foam-in-Place) Batch Preparation Pouring-in-place is the oldest, most versatile, and most popular technique for the application […]

ادامه مطلب

2024/09/22

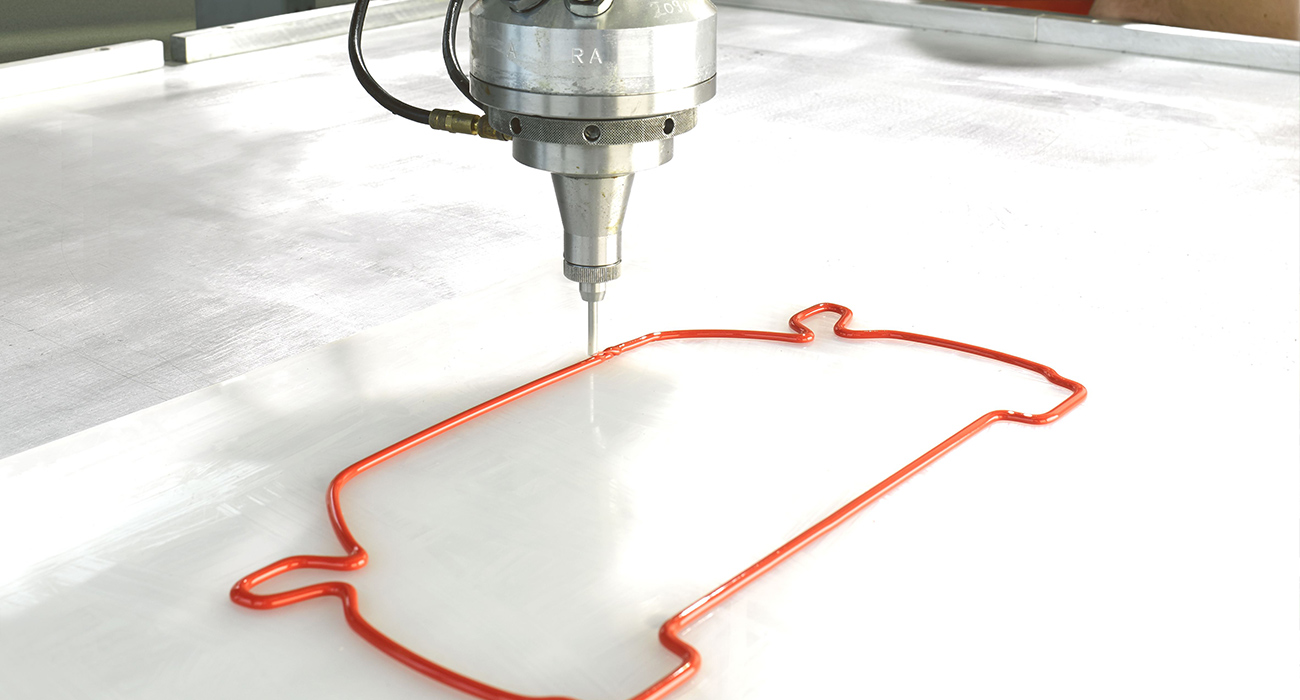

What is a form in place foam gasket or FIPFG technology?

Form in place foam gaskets (FIPFG) use polyurethane liquids that cure in air to create seamless, custom gaskets. They offer excellent adhesion, flexibility, and compressibility while minimizing waste. Ideal for automotive and electrical applications, FIPFG seals withstand temperatures from -40 °C to +80 °C and provide UV resistance. The process involves mixing components and allowing the foam to expand and cure for optimal sealing performance.

ادامه مطلب

2024/09/22

How to perform a cup test?

The cup test measures polyurethane foam properties through hand mixing. Gather supplies like cups, gloves, and a scale. Weigh the polyol and blowing agents, then mix with isocyanate at the correct temperature. Key timings to note are cream time (start of expansion), gel time (thickening), rise time (full expansion), and tack-free time (when the foam surface is no longer sticky). Finally, evaluate reaction times, density, and appearance.

ادامه مطلب

2024/09/22

Common solvents in polyurethane industry

Polyurethanes need polar solvents. Key options include:

Methylene Chloride: Effective but toxic.

Dimethylformamide (DMF): Strong solvent, high boiling point, toxic.

Acetone: Fast-evaporating, good for uncured foam, can cause condensation.

Tetrahydrofuran (THF): Flammable, excellent solvent.

N-Methyl Pyrrolidone (NMP): Safer alternative for removing cured foam.

These solvents are mainly used for cleaning equipment, though cured polyurethane resists complete dissolution.

ادامه مطلب

2024/09/22

5 common thermal insulation materials

Mineral wool (0.031-0.045 W/mK) offers good insulation and soundproofing but absorbs water. Fiberglass is cost-effective and non-combustible but can irritate lungs. Polystyrene foam (0.030-0.045 W/mK) is great for foundations but sensitive to solvents. Polyurethane foam (as low as 0.020 W/mK) provides excellent insulation and is easy to apply. Cellulose fibers (0.039 W/mK) are good for insulation and soundproofing but need ventilation. For details, contact Imen Polymer Chemie Co.

ادامه مطلب

2024/09/22

What do you know about polyurethane color paste?

Polyurethane color pastes are pre-dispersed pigment mixtures that ensure even color blending in polyurethane resins. They provide high color intensity and compatibility with various polyols, making them ideal for applications like footwear, flooring, and automotive interiors.

Advantages:

Easy dispersion

Bright, uniform color

Excellent stability

Imen Polymer Chemie Co. offers solvent-free, custom color pastes that maintain the physical properties of PU systems.

ادامه مطلب

2024/09/22

Application of polyurethane foam in toy industry

Table of contents Polyurethane (PU) is a polymeric material with excellent physical and chemical properties and can be used to make various toy products such as stuffed and elastic ones. In other words, polyurethane and thermoplastic polyurethane are essential components to children’s and pet’s toys. Not only do they have great durability, but they also […]

ادامه مطلب

2024/09/22

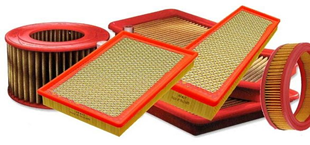

Air filter foam system

Natural rubber was once the main material for sealing devices, but silicones and polyurethanes have replaced it due to their better properties. High-density polyurethane foams are now used in automotive air filters, offering benefits like elasticity, strength, and temperature resistance. These foams contain tiny bubbles formed during production, and their manufacturing involves mixing polyols and isocyanates, with curing taking place at room temperature through an exothermic reaction.

ادامه مطلب

2024/09/18

One-component polyurethane foam (OCF)

One-component polyurethane foam (OCF) is a pre-mixed, self-expanding foam used for insulation and sealing in construction. It comes in cans, expands upon application, and cures within hours. OCF is adhesive, weather-resistant, and requires safety precautions due to its flammability.

ادامه مطلب