Table of contents Polyurethanes are polar and so you need a polar solvent. The choice of solvent to dissolve a polymer is governed by various factors, such as solvency power, volatility (moderate boiling point), toxicity and cost of solvent, the...

2024/12/31

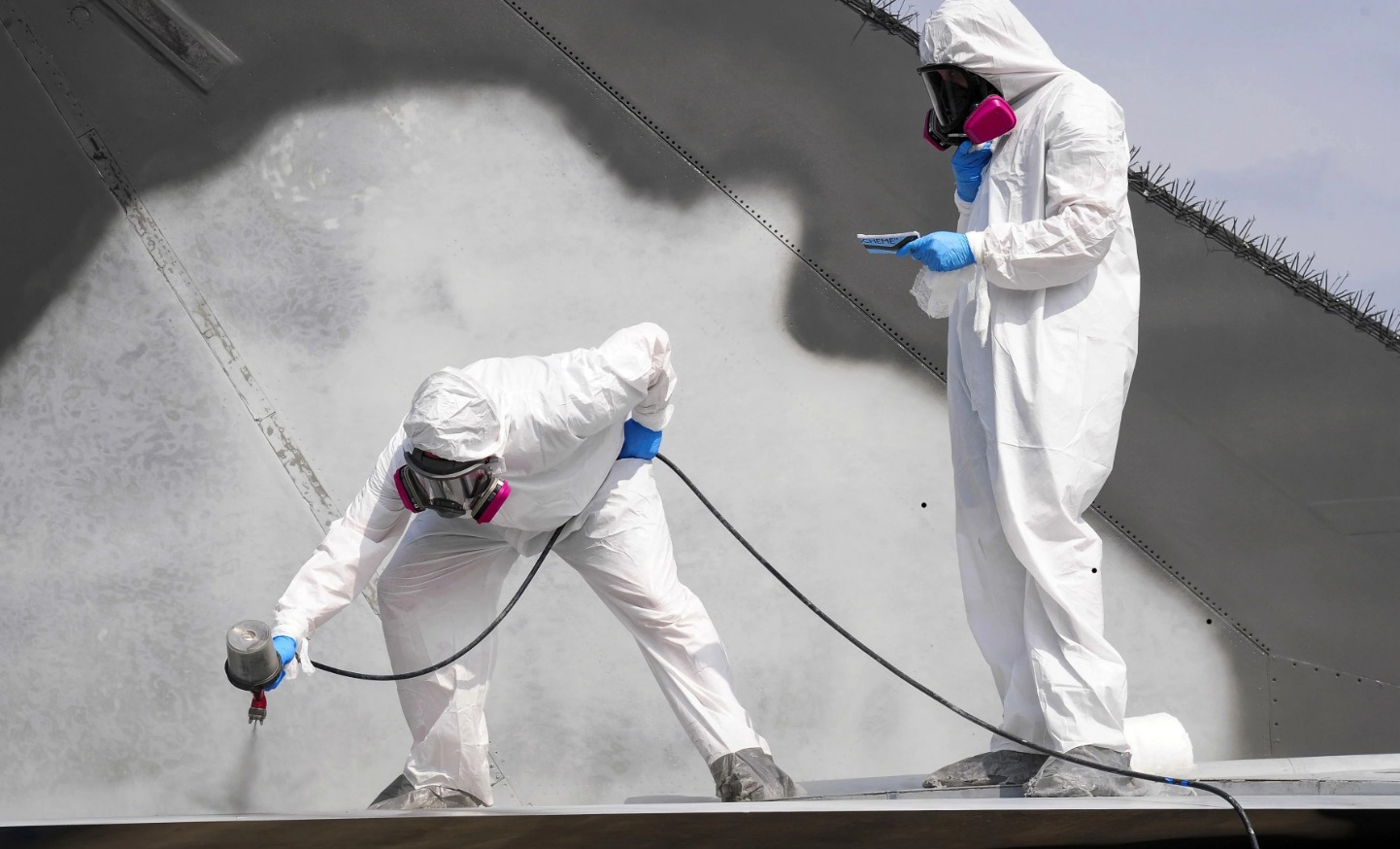

Innovative catalytic process for decomposing waste polyurethanes

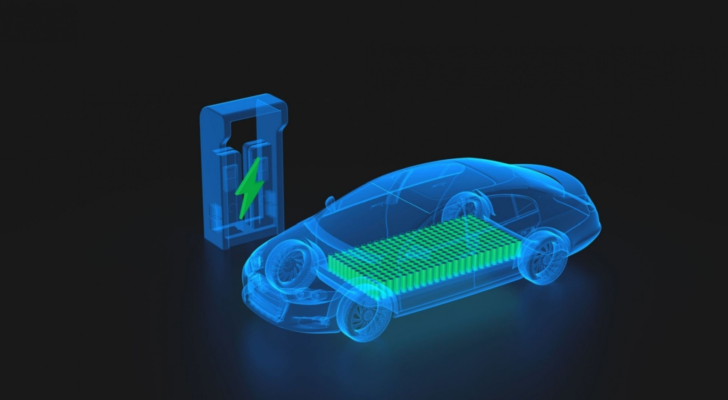

Polyurethane, widely used in industries for its durability, generates significant waste with environmental challenges. Innovative recycling methods, like a catalytic process from Peking University, efficiently convert waste into valuable materials such as polyimide and biodegradable polylactone, offering sustainable solutions.

ادامه مطلب