Automotive industry

The second largest market for polyurethanes after the construction and furniture industries is the automotive sector. In fact, polyurethane foam is a widely used polymer in the automotive industry, enhancing the quality, safety, and performance of vehicles. This foam is highly popular in the industry due to its lightweight nature, thermal insulation properties, resilience after stress application, good performance at low temperatures, chemical resistance, durability, stability, and ability to absorb sound and vibrations.

The types of polyurethane foams offered by Imen Polymer Chemie Company for use in the automotive industry include integral foam (self-skinning foam), vehicle cabin insulation foam, cold cure foam, wire harness foam, air filter foam, air and oil filter adhesives, wood imitation foam, sealing foam, and semi-rigid foam.

Product applications

These foams can be used to produce various automotive parts, including:

- Rear parcel shelf

- Sunroof

- Car seats

- Steering wheel

- Dashboard cover

- Door handles

- Bumper foam

- Gear knob

After-sales services

We never leave you

on your own afterwards either

Imen Polymer Chemie

Some of our latest

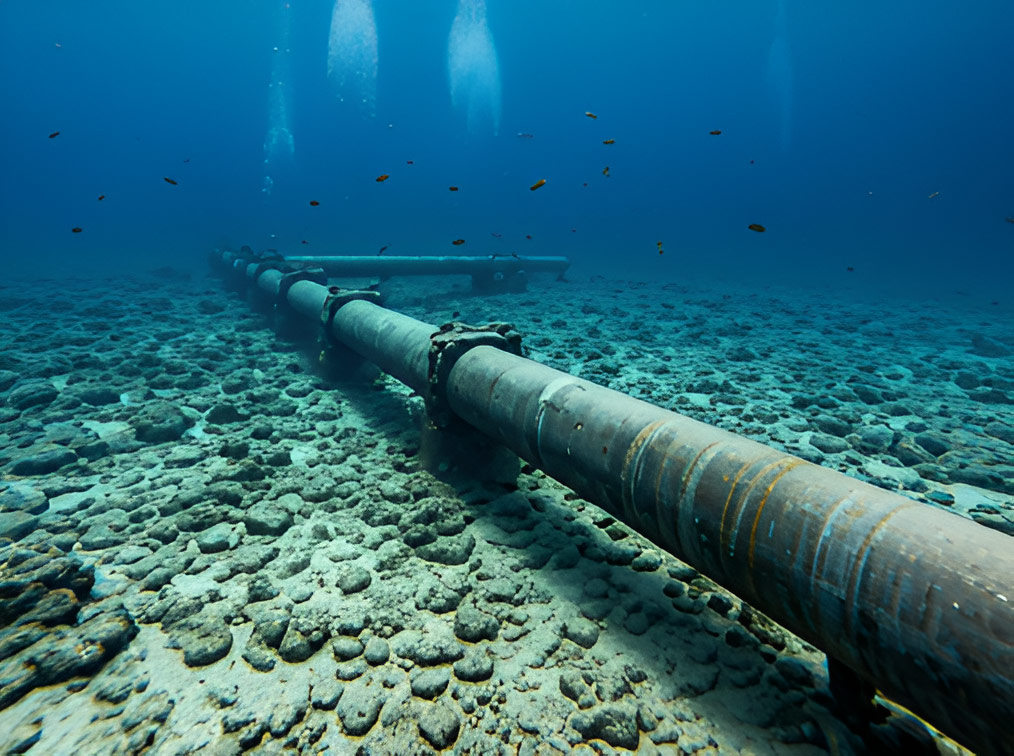

Best Thermal Insulation For Building Floors

Subsea pipeline insulation

Optimizing electricity consumption in refrigerators with polyurethane insulation

Polyurethane material in the automotive industry

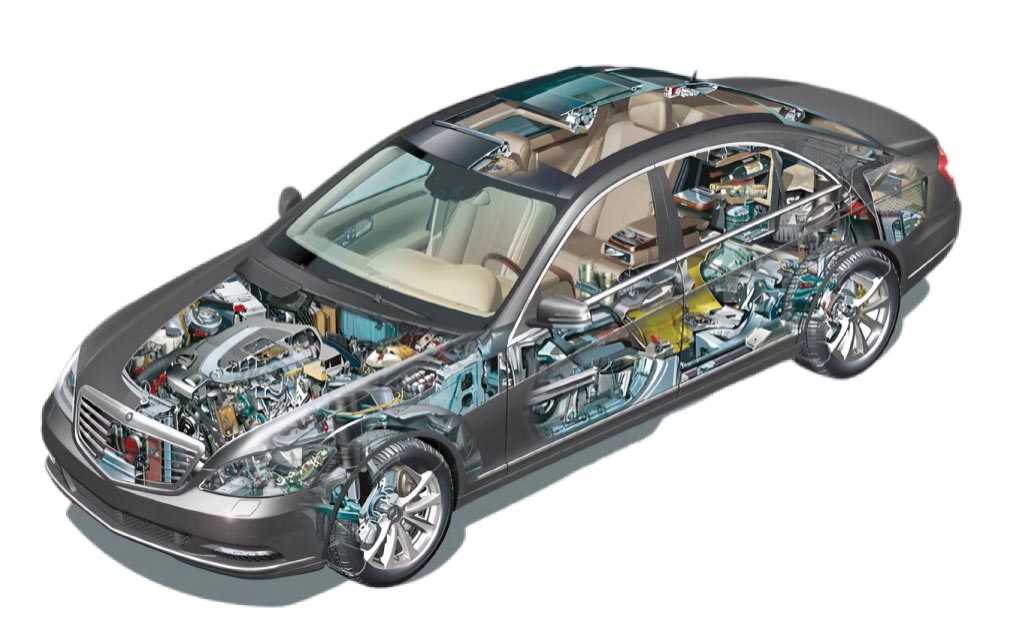

Polyurethane (PU) has become an indispensable material in the automotive industry due to its versatility, durability, and lightweight properties. From seating to insulation, Vehicle soundproofing, and coatings, polyurethane plays a crucial role in enhancing vehicle performance, safety, and sustainability. As the automotive sector move toward more fuel-efficient and environmentally friendly designs, the demand for advanced solutions continues to rise. In this article, we explore the extensive applications of polyurethane in the automotive industry and highlight why Imen Polymer Chemie is the ideal supplier of polyurethane materials in Iran and high-quality.

The benefits of using polyurethane in the automotive industry

Polyurethane offers a unique combination of flexibility, resilience, and chemical resistance, making it a superior choice for various automotive components.

In simpler terms, compared to traditional materials like rubber and metal, polyurethane materials provide significant advantages, including:

Lightweight properties:

Contributing to improved fuel efficiency and reduced emissions. Lighter vehicles consume less fuel, reducing overall emissions and improving sustainability.

High durability:

Ensuring longer service life for vehicle components.

Thermal and acoustic insulation:

Enhancing passenger comfort during driving.

Versatility:

Available in rigid, flexible, semi rigid/flexible forms, suitable for multiple applications. Also, there are polyurethane coatings, adhesives, sealants and elastomers that can be used in automotive manufacturing.

Eco-friendliness:

Supports sustainability efforts through recyclable formulations and reduced energy consumption.

Cost efficiency:

Long-lasting durability reduces maintenance and replacement costs.

Customizability:

Available in various densities and formulations for different automotive needs.

Different polyurethane foams in automotive industry

There are different types of polyurethane foams that can be used to produce automotive parts; they are as follows:

1. Flexible polyurethane foams

Flexible polyurethane foams are essential in modern vehicle interiors, providing superior cushioning, impact absorption, and durability. Found in seats, headrests, armrests, dashboard padding, and sound insulation systems, these foams enhance comfort, breathability, and vibration damping, ensuring a smoother ride.

Key types of flexible polyurethane foams used in automotive applications include:

Cold-cure polyurethane foam:

A high-resilience foam used in seating, offering elasticity, shape retention, and long-term comfort. Its open-cell structure prevents heat buildup.

Latex-like polyurethane foam:

Used in premium seats, delivering elasticity, pressure distribution, and enhanced comfort.

Acoustic insulation foam:

Applied in car cabins and engine compartments, reducing noise and heat transfer, improving passenger comfort and vehicle efficiency.

With customizable density and firmness, flexible polyurethane foams enhance interior quality while optimizing weight and performance, making them indispensable in automotive innovation.

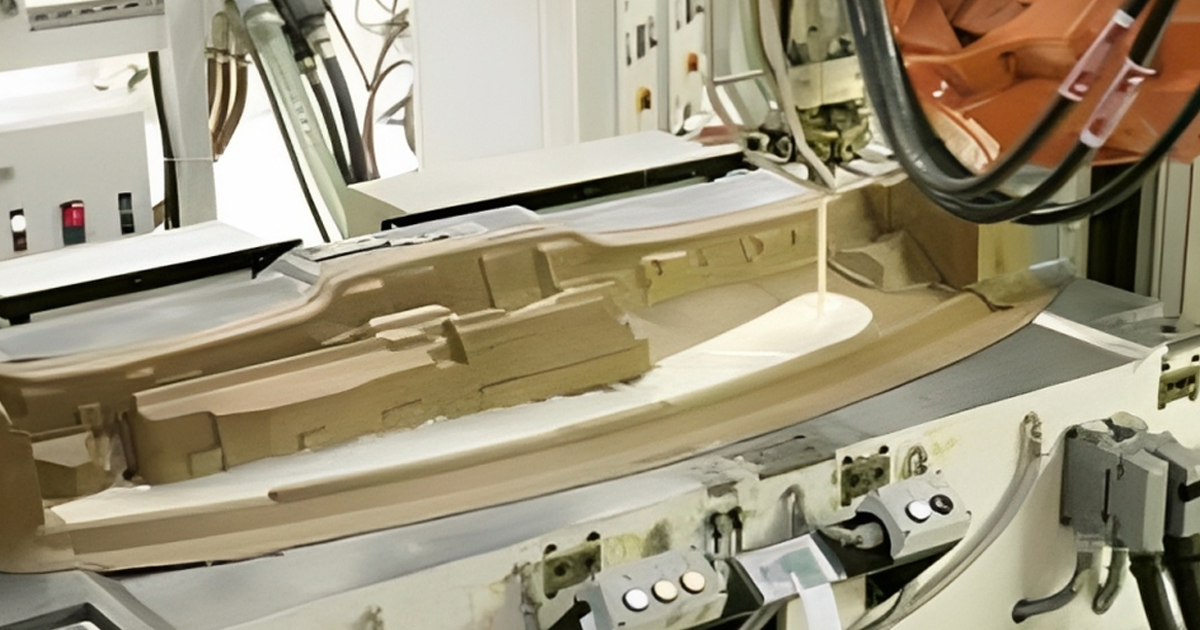

2. Rigid polyurethane foams

In the automotive industry, rigid polyurethane foam is primarily used for wood-imitation components in sunroofs and back compartments. This specialized foam refracts the look and feel of natural wood while offering lightweight durability, dimensional stability, and resistance to warping or cracking.

The use of rigid polyurethane foam in sunroofs provides structural integrity while maintaining a refined, high-end aesthetic. The material can be precisely molded in the exact product shape. Additionally, in back compartments, this material offers long-lasting strength without adding unnecessary weight, contributing to vehicle efficiency and performance. The rigid polyurethane foam does not absorb moisture, ensuring consistent performance under varying environmental conditions.

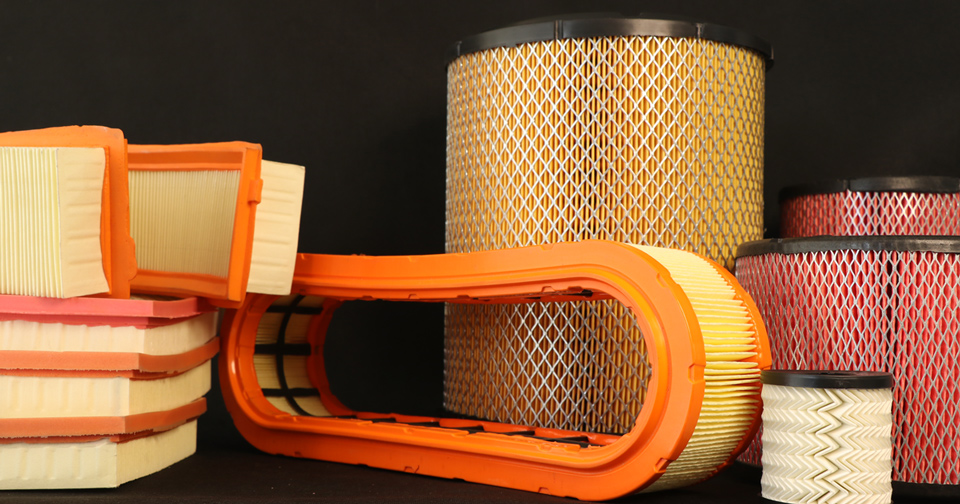

3. Elastofoams

Elastofoams (kind of polyurethane foam), are utilized in various structural and impact-resistant components in vehicles. These foams exhibit enhanced elasticity and durability, allowing them to absorb shocks and withstand mechanical stress. Some of their key applications include:

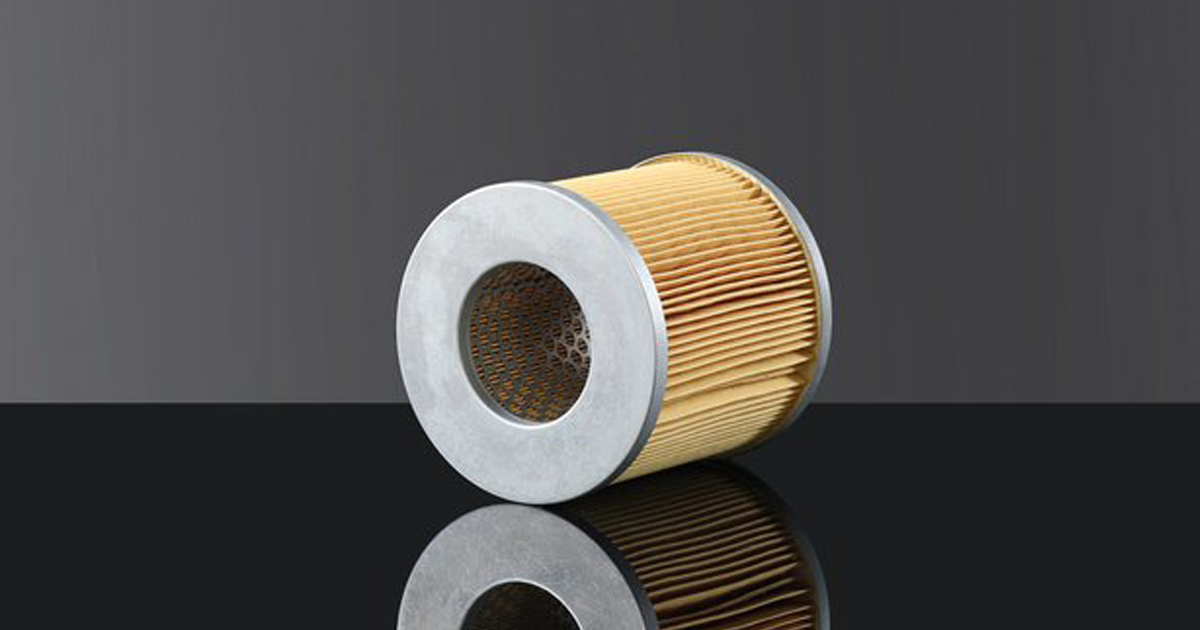

Air filter foam:

Open-cell polyurethane foams are used in automotive air filters, ensuring efficient dust and particle filtration while maintaining optimal airflow for engine performance.

Integral skin foam (self-skinning foam):

Commonly found in steering wheels, dashboards, and gear knobs, this foam type offers a tough, abrasion-resistant outer layer with a soft core for enhanced grip and comfort. Also, they are used in noise reduction panels minimizing road noise and improving overall driving experience.

Wire harness foam:

In vehicles, polyurethane elastofoam is used to encapsulate and protect wires, shielding them from vibration, abrasion, and moisture exposure. This helps improve electrical system reliability while reducing noise and wear over time.

These properties make elastofoams a preferred choice for manufacturers looking to balance strength, durability, and aesthetics in various vehicle parts. In other words, they play a vital role in enhancing vehicle performance, safety, and longevity across multiple automotive applications.

4. Semi-rigid polyurethane foam

Semi-rigid polyurethane foams play a crucial role in automotive safety and impact resistance, particularly in car bumpers and energy-absorbing structures. Their unique composition allows them to deform upon impact and return to shape, effectively dissipating crash energy and reducing damage to the vehicle’s frame. Additionally, semi-rigid foams are used in door panels and interior protective elements, ensuring occupant safety in case of an accident. Their lightweight yet resilient nature makes them an indispensable part of modern vehicle crash management systems.

Applications of Polyurethane in the Automotive Industry

Polyurethane materials are really exciting and due to their unique properties, they can be used in various sectors and applications. Diverse applications of polyurethane in the automotive industry can be categorized according to the following:

1. Seating and cushioning

Polyurethane foam is widely used in automotive seating due to its exceptional comfort, support, and durability. These foams also absorb road vibrations, reducing driver fatigue and improving ride quality.

Flexible polyurethane foam is preferred for:

• Seat cushions and backrests

• Headrests and armrests

2. Interior and exterior components

The interior aesthetics and comfort of vehicles significantly benefit from polyurethane materials. Applications include:

• Dashboard padding

• Door panels

• Steering wheels

For exteriors, polyurethane coatings protect vehicles from UV exposure, corrosion, and scratches. These coatings extend vehicle lifespan while maintaining a polished appearance.

3. Soundproofing and thermal insulation

Polyurethane foam is an excellent insulator, providing both thermal and acoustic benefits in vehicles. It is used in:

• Engine bay/compartment insulation

• Underbody and flooring insulation

• Roof and door panels insulation

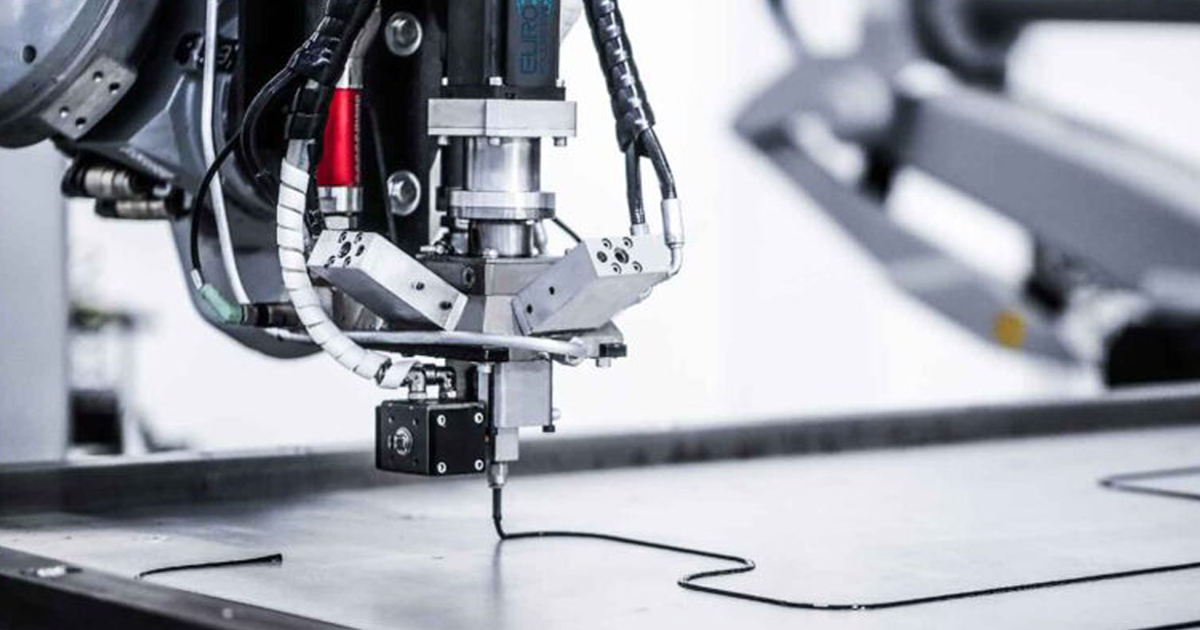

4. Adhesives and sealants

Polyurethane-based adhesives are essential in vehicle assembly, ensuring strong and flexible bonding between different materials. They provide excellent resistance to temperature fluctuations and vibrations, commonly used in:

• Windshield and window bonding

• Body panel assembly

• For interior parts, including seats, dashboards, and trim elements

5. Suspension and chassis components

Polyurethane has replaced traditional rubber in many suspension components due to its superior durability and load-bearing capacity. It is used in:

• Bushings and mounts

• Shock absorber components

• Engine and transmission mounts

6. Energy absorption and safety components

Safety is a critical aspect of automotive engineering, and polyurethane plays a vital role in:

• Impact-absorbing bumpers

• Airbag covers

• Side-impact protection panels

7. Polyurethane in electric vehicles (EVs)

With the growing shift towards electric vehicles, polyurethane is increasingly used in:

• Battery enclosures

• Lightweight structural components

• Durable coatings

Why choose Imen Polymer Chemie for automotive polyurethane solutions?

We are a leading manufacturer and supplier of high-quality polyurethane raw materials tailored for automotive applications. Here’s why our company stands out:

1. Expertise in polyurethane formulations

With years of experience in polyurethane production, we offer customized solutions that meet the unique requirements of the automotive industry. Our extensive range includes flexible, rigid and semi rigid/flexible foams, coatings, adhesives, and specialty PU products.

2. Commitment to quality and innovation

We prioritize research and development, ensuring our polyurethane materials deliver superior performance in terms of durability, thermal stability, and environmental sustainability.

3. Wide range of formulations for automotive industry

We offer a diverse range of polyurethane-based formulations specifically tailored for the automotive industry. Our products are designed for a wide variety of applications, including air filter foam, car seats, steering wheels, dashboards, sunroofs, car insulation, and more.

4. Sustainable and eco-friendly solutions

We are committed to sustainability. Our formulations include eco-friendly alternatives that align with global regulations and industry trends toward green manufacturing.

5. Reliable supply chain and technical support

In addition to a consistent supplying of polyurethane materials we offer technical support to help automotive manufacturers optimize their production processes and product performance. We never leave our customer alone.

6. Focus on customer needs

Our team collaborates closely with automotive manufacturers to understand their needs and provide tailored polyurethane solutions that enhance vehicle quality and efficiency.

We have visited and listened to automotive manufacturers. By engaging closely with them, we have gained a deep understanding of their needs and challenges, enabling us to provide solutions that truly align with their requirements. In addition, we offer customizable solutions our material formulations can be adjusted to meet specific customer demands.

Conclusion

Polyurethane is a popular material in the automotive industry, contributing to improved comfort, safety, fuel efficiency, and sustainability. With its applications ranging from seating to insulation, coatings, and structural components, PU materials play an important role in automobile manufacturing especially modern vehicle production.

As a trusted polyurethane raw material supplier, we offer high-performance, customized polyurethane solutions that meet the demanding requirements of the automotive sector. Contact us today to discover how our polyurethane materials can enhance your automotive products and manufacturing processes. Buying automotive polyurethane from Iran? Call +982157325

.