Shoe industry

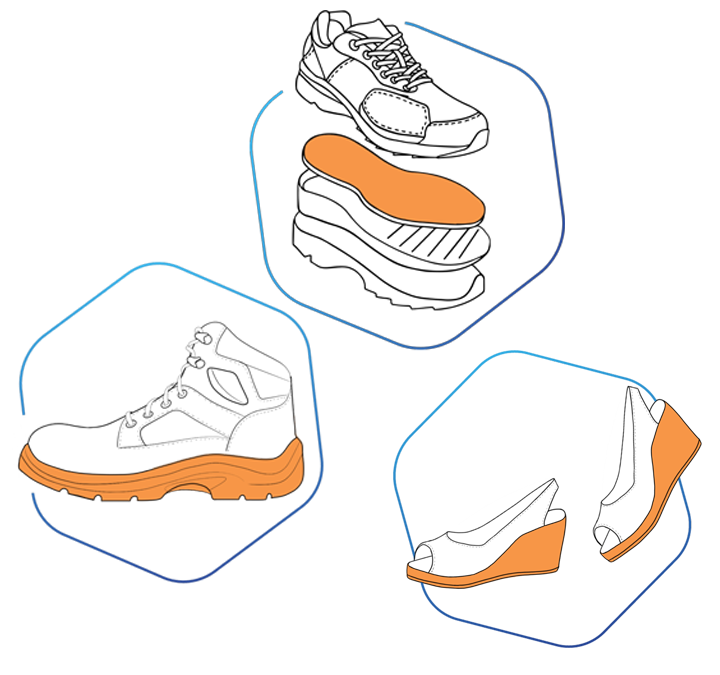

Polyurethanes have been used in the footwear industry since the 1960s and have gained significant attention from shoe manufacturers. Utilizing polyurethane materials allows for the production of lightweight, abrasion-resistant, high-quality, comfortable, and durable shoes. This polymer can be used in a wide range of footwear, from everyday shoes to safety shoes that require enhanced properties.

The types of polyurethane foams offered by Imen Polymer Chemie Company for use in the footwear industry include cold cure foam and shoe sole foam.

Product applications

Some applications of polyurethane materials in the footwear industry are as follows:

- Shoe soles

- Midsole layers

- Shoe insoles

- Orthopedic shoe insoles

After-sales services

We never leave you

on your own afterwards either

Imen Polymer Chemie

Some of our latest

What is the best car refrigerator insulation?

What are aliphatic isocyanates?

Polyurethane display refrigerator foam

Polyurethane foam in the shoe industry

The footwear industry has gone through a remarkable transformation with the incorporation of polyurethane (PU) foam. As you know, PU foam is a versatile material, that’s why is has found widespread application in various components of shoes, including midsoles, insoles, and outsoles. This article explores the scientific and practical aspects of polyurethane foam in the shoe industry, its manufacturing process, advantages, environmental impact, and future prospects.

Polyurethane foam composition for shoe soles

Polyurethane foam is produced through the reaction of polyols and isocyanates, and with the addition of blowing agent and necessary additives a cellular structure is made. The regulate balance of these raw materials (compositions) allows manufacturers to create foams with varying densities and mechanical properties, making it ideal for footwear applications. Open-cell polyurethane foams, known for their breathability and cushioning, are typically used in insoles, while closed-cell foams provide enhanced durability and water resistance, suitable for outsoles and midsoles.

Advanced manufacturing techniques, including molding and injection processes, have enabled the production of highly consistent and customizable polyurethane foams. By adjusting the formulation, manufacturers can achieve specific characteristics such as energy return, shock absorption, and lightweight performance, addressing the diverse demands of the shoe market.

Advantages of polyurethane foam in footwear industry

One of the distinct benefits of polyurethane foam in the shoe industry is its exceptional cushioning and comfort. The material conforms to the shape of the foot, distributing pressure evenly and reducing fatigue, which is particularly important for athletic and everyday footwear. Moreover, polyurethane foam exhibits superior resilience, maintaining its structural integrity over time, unlike traditional materials that compress and break down with extended use.

In other words, durability is another key advantage. Shoes incorporating polyurethane foam tend to have a longer lifespan due to the material’s resistance to abrasion, hydrolysis, and microbial growth. They are also resistant to oils, chemicals, and extreme temperatures, making them an excellent choice for industries requiring accurate safety standards. This makes it an ideal choice for high-performance sports shoes, work boots, and outdoor footwear that must endure harsh conditions.

Additionally, polyurethane foam contributes to lightweight design without compromising on support or protection. This weight reduction is particularly valuable in running and hiking shoes, where every gram counts toward enhanced performance and reduced wearer fatigue.

PU insoles vs. midsoles vs. outsoles (key differences and benefits)

Polyurethane foam is utilized in different layers of footwear, each serving a distinct function. Insoles, midsoles, and outsoles each require unique properties to enhance comfort, permanence, and performance.

Insoles, also known as footbeds, are the first point of contact with the foot and are primarily designed for cushioning and arch support. Polyurethane foam insoles have shock absorption characteristics; they also help in moisture control, reducing sweat accumulation and odor.

Midsoles act as the primary shock-absorbing layer between the insole and outsole. PU midsoles are highly resilient, offering energy return that enhances running efficiency and reduces impact stress. They are commonly found in sports and athletic footwear, where performance and endurance are critical.

Outsoles, are responsible for grip and strength. Polyurethane-based outsoles provide excellent abrasion resistance, making them suitable for tough conditions. They also exhibit great flexibility, which improves natural foot movement and overall walking comfort.

Thermoset vs. thermoplastic polyurethane soles, which one is better?

Polyurethane soles exist in two primary forms: thermosetting PU and thermoplastic polyurethane (TPU). Both have distinct properties that make them suitable for different types of footwear.

Thermosetting polyurethane undergoes a chemical curing process, making it more rigid and durable. It is commonly used in high-performance and industrial footwear where persistence and resistance to environmental factors are major. These soles provide excellent support, resistance to hydrolysis, and superior shock absorption, making them ideal for work boots and hiking shoes.

On the other hand, thermoplastic polyurethane (TPU) is a flexible and durable alternative with high resistance to abrasion and chemicals. TPU soles offer better elasticity and are commonly found in sports and fashion footwear, where flexibility and aesthetics are crucial. Additionally, TPU is easier to recycle, making it a more environmentally friendly option in sustainable footwear manufacturing.

Dual density polyurethane soles

Dual-density PU- soles, which provide the ideal balance of comfort and durability, are changing the footwear business. Two distinct layers are used in this technology: a stronger outer layer for wear resistance and a softer inner layer for cushioning.

The inner layer, typically made of lower-density PU foam, provides excellent shock absorption, reducing the pressure on the feet when standing or walking for extended periods of time. This makes dual-density soles a preferred choice for work shoes, safety boots, and orthopedic footwear. High-density PU used to make the outer layer guarantees durability and resilience to harsh environmental factors like chemicals, abrasions, and extremely high or low temperatures.

These soles have gained popularity in work boots and industrial footwear, where prolonged wear and exposure to rough surfaces require enhanced durability. Additionally, this design helps reduce fatigue and improves overall foot support, making it a superior choice for professionals who need both safety and comfort in their daily tasks.

Sustainable innovations for shoe sole manufacturing

While the production of polyurethane foam traditionally relies on petrochemical-based polyols, the industry is witnessing a shift toward more sustainable practices. Bio-based polyols, derived from renewable resources such as castor oil or soybeans, are increasingly being integrated into polyurethane formulations. This transition not only reduces the carbon footprint of manufacturing but also aligns with the growing consumer demand for eco-friendly footwear.

Recycling is also gaining traction, with manufacturers developing closed-loop systems to repurpose polyurethane waste into new foam products. By improving the recyclability of polyurethane foam, the shoe industry is taking significant steps toward reducing landfill waste and promoting a circular economy.

Polyurethane applications in different types of footwear

Polyurethane foam has become an essential part of the footwear industry. Its applications cover various types of footwear, each benefiting from the material’s distinct properties.

Orthopedic footwear

These kinds of shoes also benefit significantly from polyurethane foam, as it can be engineered to provide targeted support for individuals with foot ailments.

Sandals

For casual and open footwear like sandals, PU soles offer a lightweight yet supportive foundation.

Athletic footwear

Athletes require shoes that can absorb impact and provide energy return. PU midsoles are engineered to offer excellent shock absorption, reducing strain on the joints during high-intensity activities.

Casual and fashion footwear

In everyday shoes, PU insoles and outsoles enhance comfort and style. The cushioning effect of PU insoles provides a comfortable walking experience, while the material’s versatility allows designers to create aesthetically pleasing outsoles that do not compromise on comfort or durability.

The adaptability of polyurethane foam makes it a material of choice across various footwear applications, meeting the diverse needs of consumers while maintaining high standards of performance and comfort.

Why choose Imen Polymer Chemie for shoe sole materials?

With decades of experience, we develop high-performance polyurethane systems for shoe soles. We have:

Expertise in polyurethane formulation

Our materials meet international quality standards, making us a trusted partner for footwear manufacturers.

Advanced R&D and customization solutions

Our R&D team creates innovative formulations tailored to different footwear needs. We offer customized densities, hardness levels, and color-adjustable polyols to enhance both performance and aesthetics.

Superior product performance

Our polyurethane materials provide excellent abrasion resistance, elasticity, and thermal stability. This ensures long-lasting shoe soles that maintain their structure and comfort over time.

Technical support and consultation

Beyond supplying materials, we offer expert guidance on formulation selection, application techniques, and process optimization

Global export capabilities

With reliable logistics and compliance with global standards, we ensure seamless exports to various footwear producers worldwide. Also, we can change our polyurethane raw materials formulations to be compatible with different climates and manufacturing conditions.

To put it in a nut shell, Imen Polymer Chemie combines innovation, reliability, and expert support to deliver high quality polyurethane solutions for the footwear industry. Contact us today to enhance your shoe sole production.

The future of polyurethane foam in footwear

As the demand for high-performance and sustainable footwear continues to rise, polyurethane foam technology is evolving to meet new challenges. Some promising innovations include:

Smart polyurethane materials:

Advancements in material science are leading to the development of temperature-regulating foams and antimicrobial treatments, enhancing hygiene and comfort in footwear.

3D printing with PU foams:

The rise of additive manufacturing is enabling the on-demand production of custom polyurethane shoe components, reducing material waste and expanding design possibilities.

Nanotechnology integration:

By manipulating polyurethane’s microstructure at the nanoscale, manufacturers can further improve durability, energy return, and lightweight properties, setting new standards for performance footwear.

In fact, polyurethane foam is shaping the future of footwear with smart materials, 3D printing, and nanotechnology, enhancing comfort, sustainability, and performance.

Conclusion

Polyurethane foam has undoubtedly changed the shoe industry, offering a unique combination of comfort, long term durability, and design flexibility. As the industry moves toward more sustainable and technologically advanced solutions, polyurethane remains a key player in shaping the future of footwear.

Companies like Imen Polymer Chemie, with their expertise in polyurethane raw materials, are at the forefront of this transformation, providing high-quality solutions that meet the evolving needs of the global shoe market.

As a trusted polyurethane raw material supplier, we offer high-performance, customized polyurethane solutions that meet the demanding requirements of the automotive sector. Contact us today to discover how our polyurethane materials can enhance your automotive products and manufacturing processes. Buying automotive polyurethane from Iran? Call +982157325

.