Packaging Industry

Polyurethane is a highly versatile and popular material with numerous applications in the packaging industry. It has significantly advanced the production and use of packaging materials, transforming the packaging industry. Polyurethane packaging foam possesses flexibility, insulation properties, and resistance to shocks and impacts, thus ensuring the protection of products against potential damages. These types of packaging are formed on-demand according to the specifications of customers, helping in packaging products of various sizes, shapes, and specific characteristics (such as heavy or sharp-edged).

In general, intelligent use of polyurethane in packaging design and production can greatly contribute to improving product quality and customer satisfaction. This foam is provided by Imen Polymer Chemie Company.

Product applications

This product can be used for packaging a variety of items, including:

- Packaging of chinaware

- Packaging of special art supplies

- Packaging of antiques

- Packaging of musical instruments

- Packaging of computers

- Packaging of delicate items such as military equipment

- Packaging of fragile items such as awkward chandeliers

After-sales services

We never leave you

on your own afterwards either

Imen Polymer Chemie

Some of our latest

What is the best car refrigerator insulation?

What are aliphatic isocyanates?

Polyurethane display refrigerator foam

Polyurethane in the packaging industry

Packaging is more than just a container; it is a critical element in protecting products, maintaining quality, and ensuring safe transport. Polyurethane has emerged as a leading material in modern packaging due to its versatility, durability, and ability to be engineered for a wide range of applications. From cushioning delicate electronics to supporting heavy industrial components, polyurethane foams provide reliable protection while reducing waste and improving efficiency.

This article explores the role of polyurethane in packaging, its key benefits, types, applications, environmental considerations, and trends shaping the future of this high-performance material.

The role of polyurethane in modern packaging solutions

The packaging industry has undergone remarkable transformation in recent years, driven by the need for higher product protection, improved efficiency in transportation, and the demand for reliable packaging that meets international quality expectations. Among various materials used today, polyurethane has become one of the most advanced and versatile options for industrial and commercial packaging. Its unique chemical structure allows it to be engineered into foams with different densities, hardness levels, and mechanical properties, making it suitable for protecting products ranging from sensitive electronics to heavy industrial components.

With supply chains placing greater importance on keeping products safe and intact, polyurethane has become a preferred choice for businesses seeking packaging that performs consistently and can be tailored based on the needs of each item. As global demand for safe and professional packaging continues to rise, polyurethane offers manufacturers innovative solutions that enhance protection and optimize the stability and efficiency of shipping and storage operations. This material’s unique properties allow businesses to meet the increasing expectations of consumers, ensuring that products are delivered in optimal condition while also facilitating a more streamlined logistical process.

Key benefits of using polyurethane in packaging materials

One of the greatest advantages of polyurethane in packaging is its ability to absorb shock and vibration. The material’s controlled cellular structure allows it to distribute impact forces evenly across a surface, significantly reducing the risk of damage during handling, transport, or storage. This level of protection is especially valuable when dealing with products that have high commercial value, sensitive components, or delicate internal structures that may fail under even minor mechanical stress.

Another major benefit of polyurethane packaging materials is their long-term performance and dimensional stability. Unlike many traditional packaging materials that break, deform, or lose their shape over repeated use, polyurethane can mostly maintain its structural integrity even under heavy compression. This durability ensures reliable product protection and reduces packaging waste, replacement frequency, and logistical costs over time.

Types of polyurethane used in the packaging industry

In the packaging industry, polyurethane is primarily used in the form of flexible foam, but it comes in two different production approaches depending on how the protective insert is created.

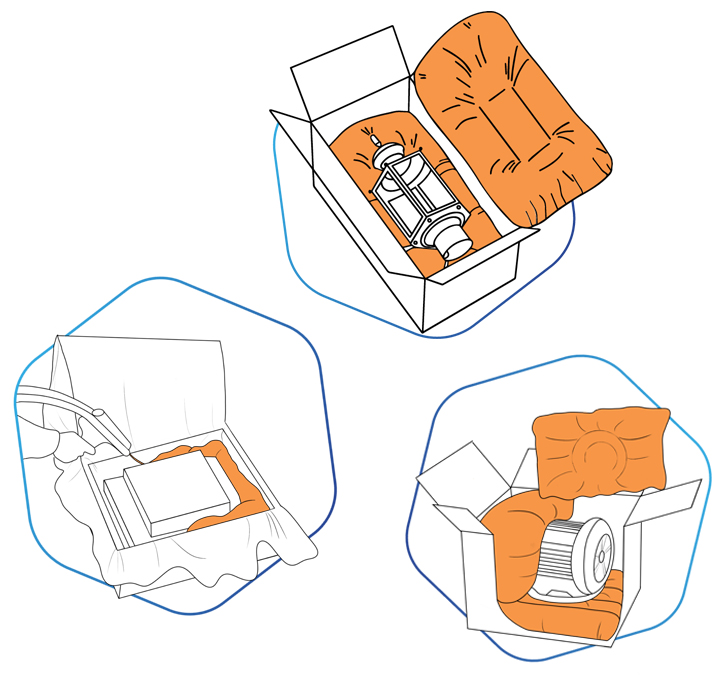

The first type is pre-produced polyurethane foam blocks, which are manufactured in large slabs and later cut into the desired shapes using industrial cutting tools such as contour cutters, CNC systems, or manual trimming equipment. This method is ideal for creating protective inserts, corner pads, cushioning layers, and custom-shaped pieces where consistent dimensions and repeatable production are required. Although the foam itself is flexible, the formulation may be adjusted to achieve different levels of softness, rebound behavior, density, or impact absorption depending on the application.

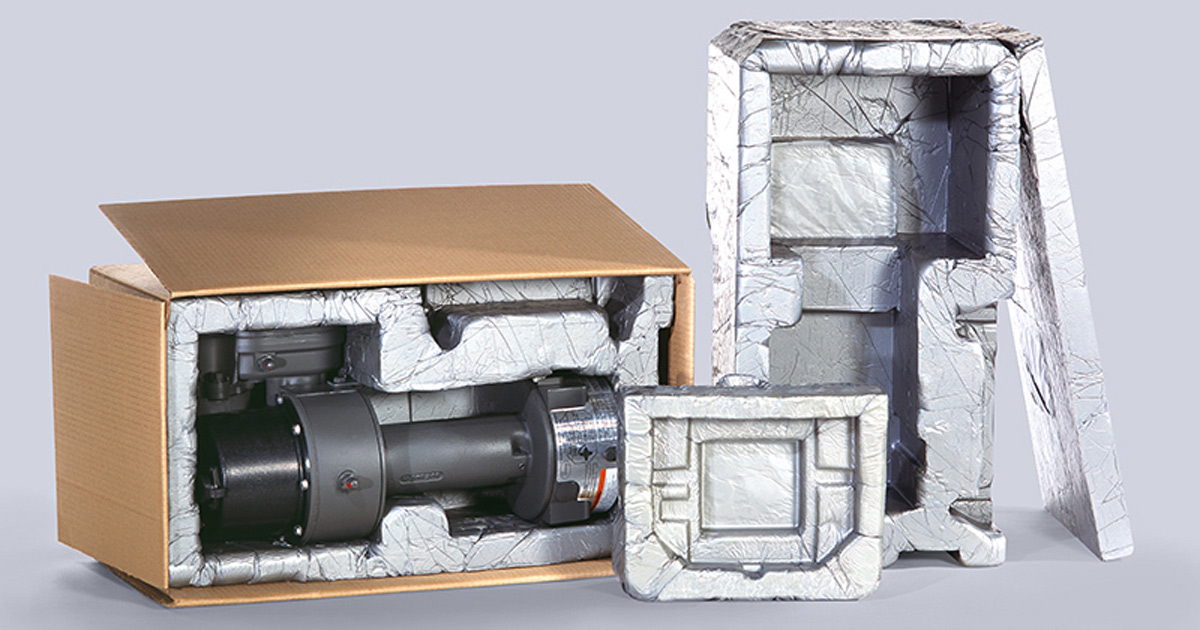

The second type is foam-in-place polyurethane, where the two components are mixed at the moment of use and poured or injected directly around the product or inside the packaging. In this process, the foam expands and forms a custom-fitted protective layer that conforms precisely to the shape of the item. This approach is especially useful for irregular, fragile, or high-value products that require complete void-free cushioning and maximum shape conformity. While both methods use flexible polyurethane foam, the formulation for foam-in-place systems is engineered to expand reliably, cure quickly, and create stable cushioning directly inside the shipping container.

Comparison of polyurethane with other packaging materials

When compared to expanded polystyrene, cardboard, polyethylene foams, or other conventional packaging materials, polyurethane offers several clear performance advantages. It provides superior impact distribution, more accurate product fit, and better resistance to deformation over time. Polyurethane can be tailored to fit the exact needs of each product, which gives it a clear advantage over standard packaging materials that can’t offer the same level of customization or protection.

Polyurethane might look more expensive at first compared to some traditional materials, but its real value shows up when you consider the total cost over time. It helps reduce product damage, lowers return rates, lasts longer, and doesn’t need to be replaced as often. For companies that export, work with delicate products, or face high costs when items get damaged, polyurethane becomes a smart, cost-effective investment in the long run.

Environmental impact and sustainability of polyurethane packaging

Environmental considerations continue to influence material selection in modern industries, and polyurethane has been the focus of considerable development in this area. Manufacturers are increasingly adopting more efficient production technologies, optimizing formulations to reduce waste, and improving recycling options for polyurethane foams. While polyurethane is not yet fully biodegradable, ongoing research has led to new pathways for chemical recycling, allowing the base polymers to be broken down and reprocessed into new materials.

Additionally, the high performance and durability of polyurethane contribute indirectly to sustainability. Because polyurethane packaging lasts longer and protects products more effectively, manufacturers experience lower rates of damaged goods, fewer transport failures, and reduced material consumption over time. In many applications, polyurethane allows companies to create single-material packaging solutions that replace bulky, multi-layer assemblies, decreasing both weight and resource usage in logistics operations.

Common applications of polyurethane in food and industrial packaging

In the industrial sector, polyurethane is widely used to protect automotive components, electronic assemblies, household appliances, laboratory equipment, aerospace components, and precision instruments. These products often require packaging that prevents movement, isolates vibration, and resists mechanical shock. Polyurethane foams can be molded to fit the exact geometry of the product, eliminating internal voids and significantly enhancing protective performance. This adaptability also helps manufacturers achieve professional presentation quality, which is essential in high-value product markets.

In food packaging, polyurethane is used in applications such as insulated containers, temperature-stabilizing packaging systems, and protective structures for transporting perishable goods. While polyurethane itself is typically not used in direct food contact without certification, its ability to maintain temperature and protect goods from external impact makes it a popular choice in cold-chain transport systems. These applications are especially relevant in modern distribution channels where food safety, freshness, and consistency must be maintained for long distances.

Future trends and innovations in polyurethane-based packaging

Advancements in polymer science are driving exciting innovations in the field of polyurethane packaging. New formulations with improved fire resistance, antimicrobial properties, greater recyclability, and enhanced impact absorption are being developed to meet the needs of emerging industries. Additionally, automation and digital manufacturing techniques are allowing polyurethane foams to be produced with even greater precision, ensuring a better fit around products and more efficient use of materials throughout the packaging process.

Sustainability will also play a critical role in the evolution of polyurethane packaging. With market demand shifting toward environmentally responsible materials, the industry is moving toward greener polyol systems, bio-based raw materials, and closed-loop recycling systems. As these technologies become commercially widespread, polyurethane will strengthen its position as a high-performance and future-ready packaging material capable of balancing durability with environmental responsibility.

Purchasing polyurethane materials from Iran for packaging

Iran hosts several reputable producers of polyurethane raw materials, among them Imen Polymer Chemie, a trusted supplier of polyols and formulated systems specifically developed for in-place polyurethane packaging foams. Manufacturers of any scale—whether small workshops or large industrial plants—can source their required materials directly from us and rely on stable quality, precise formulation control, and dependable technical guidance. These materials are engineered to deliver consistent expansion, cushioning performance, and process reliability, making them suitable for customized protective packaging applications.

In addition to supplying raw materials, we provide guidance on proper handling and processing to help manufacturers achieve stable production performance and optimal foam characteristics. This support enables producers to achieve the desired density, mechanical properties, and packaging protection without complex development steps. With strong production capability and export experience, Iran has become a competitive source for polyurethane materials in global industrial markets.

Polyurethane has established itself as one of the most capable and adaptable packaging materials in modern industry. Its ability to deliver superior product protection, maintain dimensional stability under stress, perform reliably in a wide temperature range, and be engineered to meet specific industrial needs makes it a preferred choice among manufacturers worldwide. With continuous advancements in chemistry, sustainability initiatives, and foam processing technologies, polyurethane will continue to shape the future of packaging in numerous commercial and technical sectors.

Companies looking to enhance packaging performance while controlling long-term costs can benefit significantly from polyurethane-based solutions. By sourcing high-quality polyurethane raw materials from reliable suppliers such as Imen Polymer Chemie, manufacturers can produce packaging systems that deliver durability, professional performance, consistent quality, and value across the entire supply chain. Polyurethane continues to drive innovation in packaging, offering a powerful combination of material science, engineering flexibility, and industrial practicality for today’s dynamic global market.