Table of contents

Sealing systems can be based on different materials such as polyurethanes and silicones. Form in place foam gaskets (FIPFG) are liquids based on polyurethanes that once on the surface, they have to undergo air-curing. They are widely used to reduce necessity in various sizes and shapes of the gaskets so they can be applied to different surfaces to make better sealing properties of the gaskets, making them seamless. It is possible to change dimensions of the cure-in-place gaskets in the range of 6mm to 20mm and modify density of the gaskets, depending on the doors dimensions and sealing properties of electric DB boxes with saving insulating requirements.

Most of the foam materials being applied are thixotropic and have high viscosities which stops them from losing their shape when sat on the surface. The component blend is poured into a cavity or a mold or directly applied onto a substrate, depending upon the application. The foam gaskets are processed using FIPFG or FIPG (formed in place gasket) technology. FIPG technology is widely used in automotive industry, electronic industry, electricity and lightening where required to reach a high sealing properties.

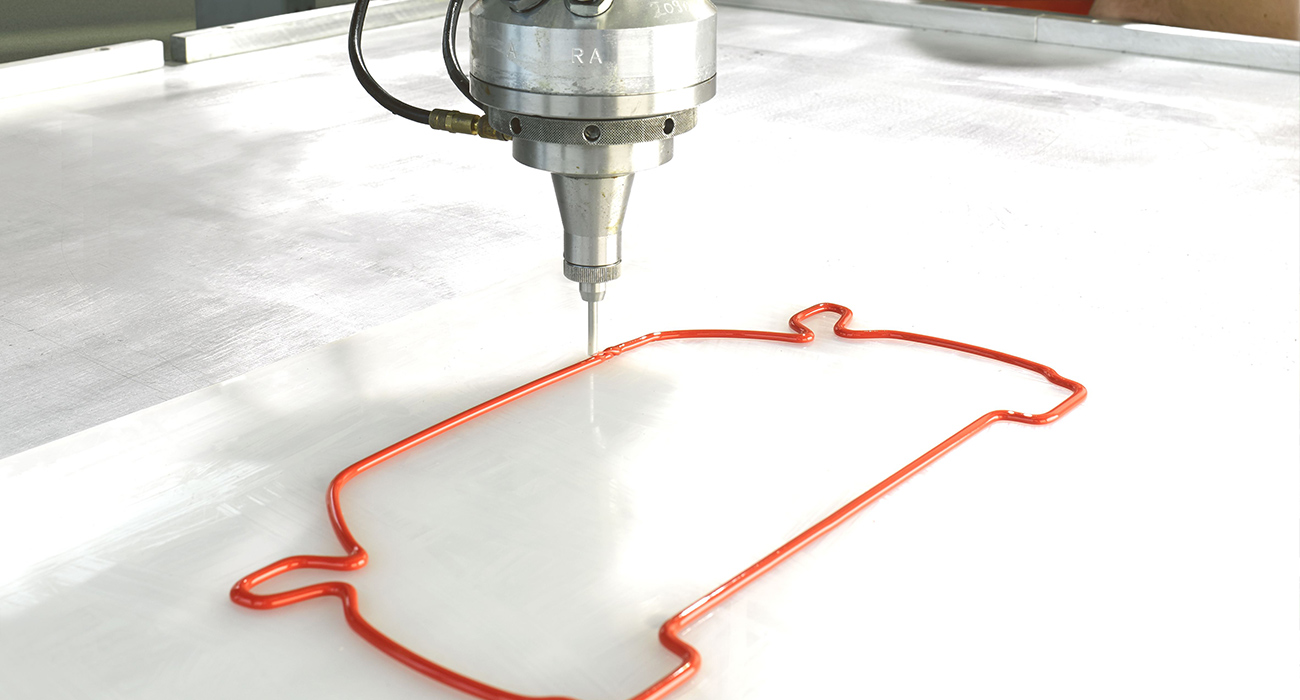

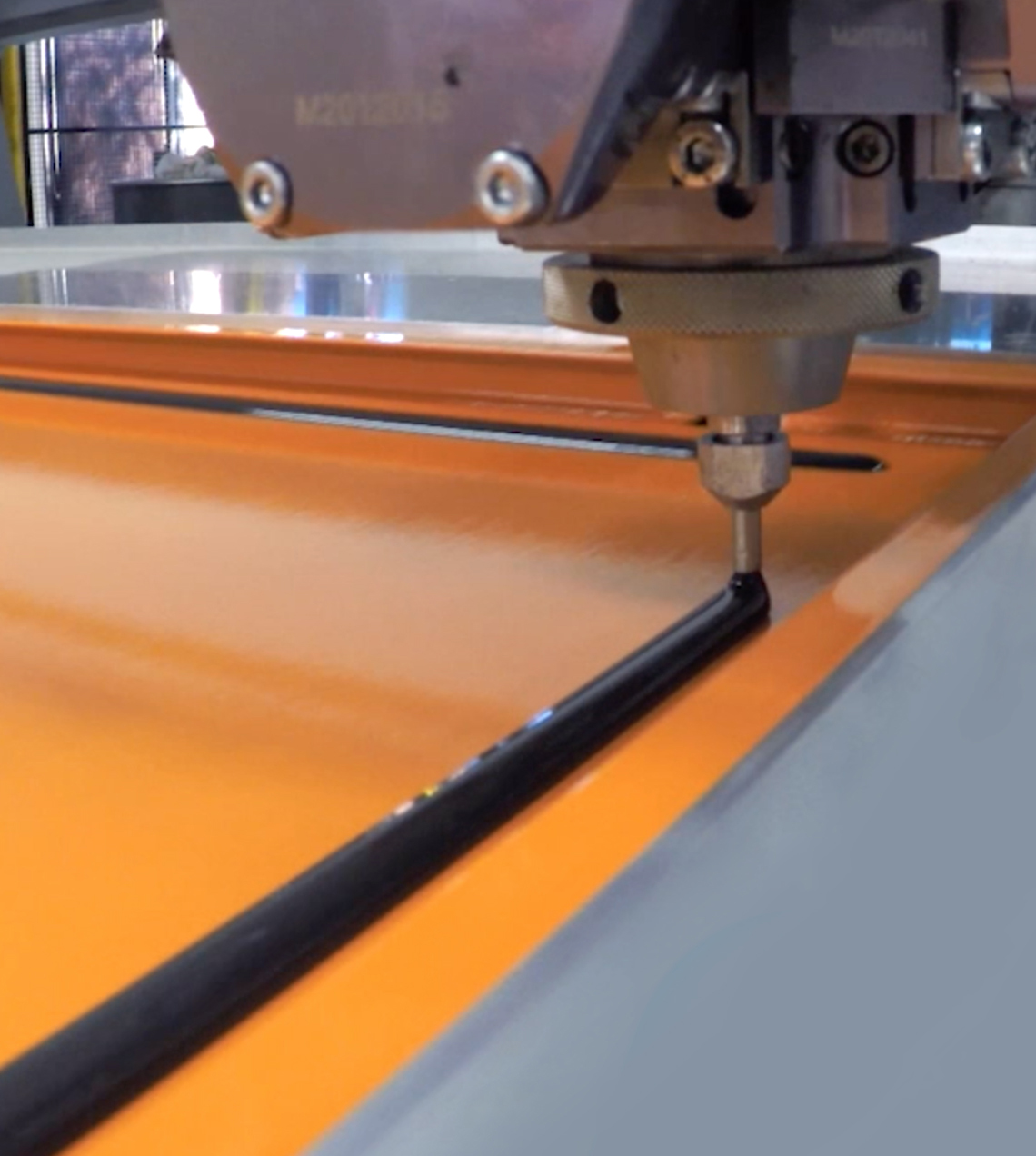

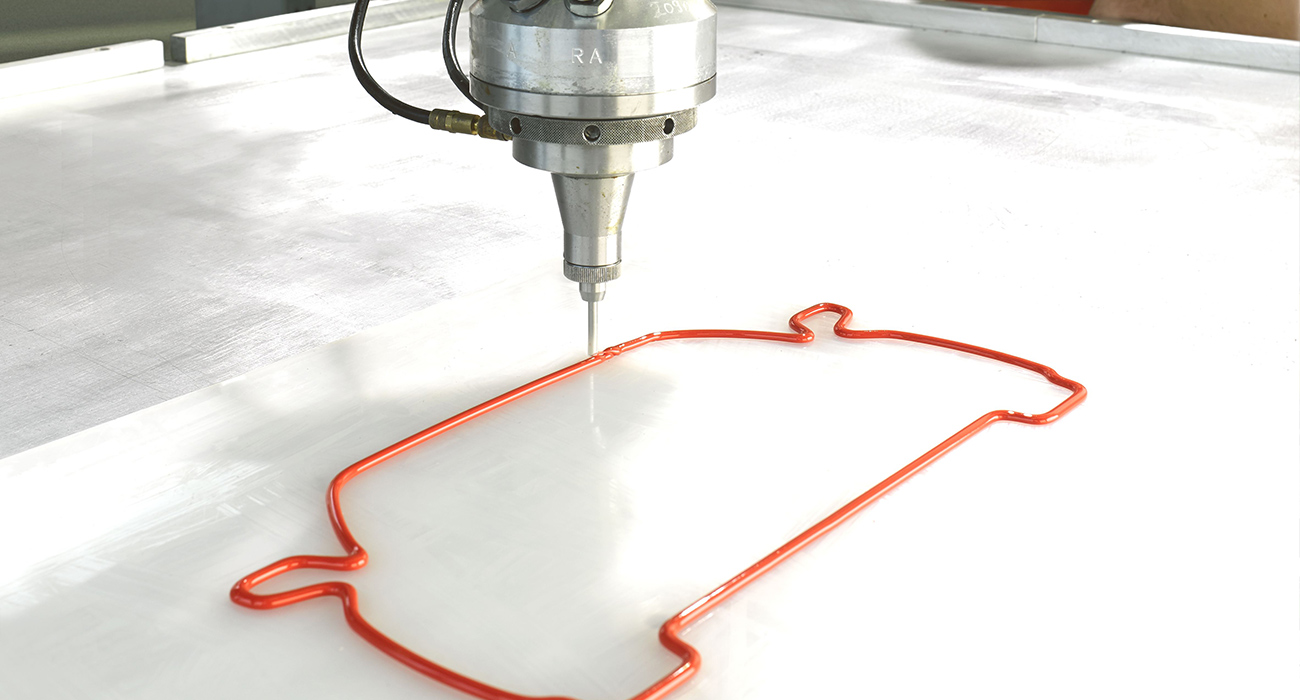

The internal space of the electrical enclosures must be clean, dry, away from moisture and dust to make the internal components run well that is why sealing is a very important manufacturing process in the production of electrical enclosures. In the past, we seal the doors by sticking sealing strips by hand, which is low efficiency and easy to cause quality problems. Foam in place gasket is a two component modified polyurethane resin that serves as the ultimate gasket for various enclosures. Polyurethane gaskets can be automatically fixed in position; they can stick without additional adhesive tape.

These gaskets are a newer alternative to conventional sealing methods. The aim of using a formed in place seal is to create a truly bespoke seal that is applied directly to the part. This means the seal is bonded onto the part either onto a flat surface or more often, into a groove which ensures that the most intimate seal can be formed with high quality and any surface imperfections do not affect the seal performance as the seal will fill the gaps and not just sit on the surface; accordingly, by using a formed in place seal the steps of the production process will be reduced.

Key features and benefits of form in place gaskets Include:

- Less waste

- Excellent adhesion

- Low compression set

- Excellent flexibility and elastic recovery

- Excellent compressibility

- Able to cover all the surfaces with complex sealing areas

- It saves time and money by removing the need for machined groove paths and worrying about gland fill in those paths. Furthermore, these gaskets are dispensed directly onto the sheet metal component by CNC robots, which is economical and don’t need additional work to assemble the product.

In order to understand how a sealant performs outdoors, it is important to look at its resistance to sunlight. In the presence of UV light, an organic material (polyurethane), begins to deteriorate by losing its properties over time, But silicone, an inorganic material, this does not happen thus provides high UV resistance. In polyurethane gaskets, properties such as hardness, adhesion strength, thixotropy and flexibility can be easily manipulated according to need. Its mechanical strength and adhesion strength can be increased to very high levels compared to silicone gaskets. For applications in the temperature range from -40 °C to +80 °C, polyurethane seals are suitable for sealing against dust and moisture. Overall, the fundamental benefits of liquid injection gaskets are their easy processes and good conformity with counter face. These gaskets can expand after injection remarkably, thus making a good contact with flanges to save on energy cost, efficiency, and decrease workload.

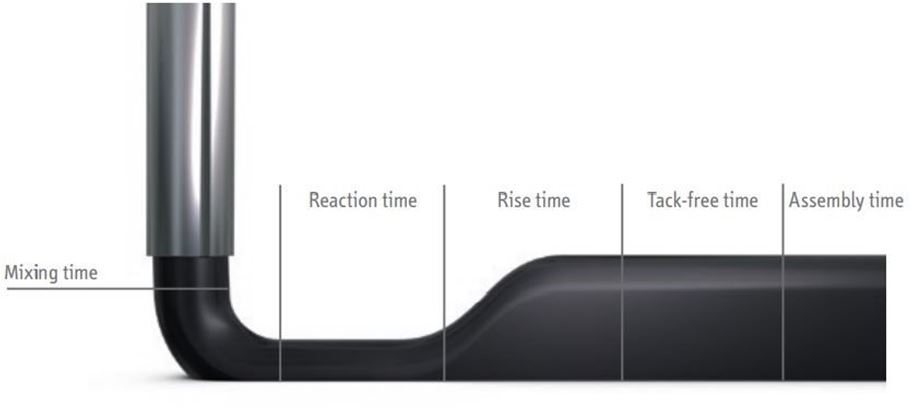

The foaming process of FIPG is illustrated above, after mixing the components (mixing time) and during the reaction of foaming system (reaction time), the volume of dispensing a liquid gasket is constant, after a specific period of time, the material began to rise and expand (rise time) to form the seal body. Tack free time is the time when the seal surface can be touched without causing damage. The last time is the assembly time that the system can bear load.