Table of contents

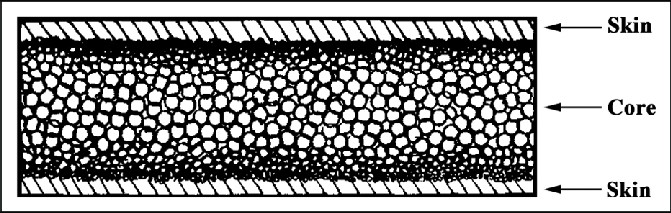

Polyurethane foam mouldings or Integral skin or Self Skin moulding is one of our unique products here at Imen Polymer Chemie. This product consists of two main components, polyol and isocyanate, which exist liquid in the room temperature, after being selected in a relatively special ratio, it is injected into a mold and forms the final shape of the mold. After selecting a specific ratio, it is injected into a mold and forms the final shape of the mold. The typical properties of our Integral Skin Polyurethane Foam systems are determined by the soft porous foam core and a compact, dense boundary zone. In fact, this product has two different densities in the core and skin of the foam, which distinguishes it from other flexible foams. The skin formed during the molding process protects the microcellular foam core with a predetermined hardness. The formed skin has a thickness of about 2 mm and the final shape of the product is such that this skin is formed leather-like on the product, therefore these products are called Integral Skin Foam.

The surface of the skin is smooth and is resistant to abrasion and chemicals. This skin, which consists of closed cells, is flexible and tear-resistant.

The integral structure of Integral Skin Polyurethane Foams can on the one hand be realized by the usage of physical blowing agents, they condense at the mould surface and initiate the skin formation. On the other hand, water is another option of foaming agents in this product.

This product has the ability to be painted and can be supplied in various colors. In addition, it is possible to cover the foam surface by using In-mold Coating (IMC) and make it more resistant to ultraviolet light and abrasion.

In what industries is this product used?

- Automotive:

– Headrest and armrest

– Chair handle

– Cable sheathing

– Car insole

– Car engine protection pad

– Steering Wheels

- Furniture:

– Types of chairs (waiting rooms, laboratories, etc.)

– Chair handle

- Medical Application:

- Operating room bed

- Operating room pad

Features and properties of Integral Skin Polyurethane Foam

Integral Skin polyurethane Foam of Iman Polymer Chemie Co has the following properties and characteristics:

– Adjust hardness with Shore A in the range of 20-80

– Density 80-600 kg per cubic meter

– Good abrasion resistance

– Resistant to chemicals

– Excellent paintablity

– Suitable skin thickness (2 mm)

– Excellent tensile properties

In addition to the mentioned features, this product can have more special properties due to its application:

– Flame resistance

– Resistance to UV light

– Antistatic

– Ability to use physical and chemical foaming agents

How to process the product

This product, as mentioned earlier, can be in 2 parts or more. If the product uses physical foaming agents such as R11 or 141-b gas, in addition to the two components polyol and isocyanate and foaming agent, color paste may be added to the polyol if required. Eventually increases to four components. To produce the Integral Skin Foam, before injecting the material in mold, it is necessary to cover the mold with a special release agent of this foam. In some cases, after applying the release agent, In-mold Coatings are used to enhance and increase the properties of the foam skin. The mold temperature should be 40-50 °C. Molding temperature is one of the main factors affecting the skin thickness of this product, with increasing mold temperature, the skin thickness also decreases. Molding time of this product is 2-6 minutes.