Table of contents

Polyurethane foam packaging is an open cell material, has a density of from about 8 to about 15 kilograms per cubic meter, which is primarily used to protect and support lighter weight, delicate product with high fragility. The purpose of polyurethane foam in packaging is to act as a shock absorber, protecting a moving packaged object from damage as it meets impact resistance. Industry sources suggest that polyurethane foam that can absorb impacts efficiently and repeatedly, is appropriate for packaging fragile items within a wide range of weights and sizes.

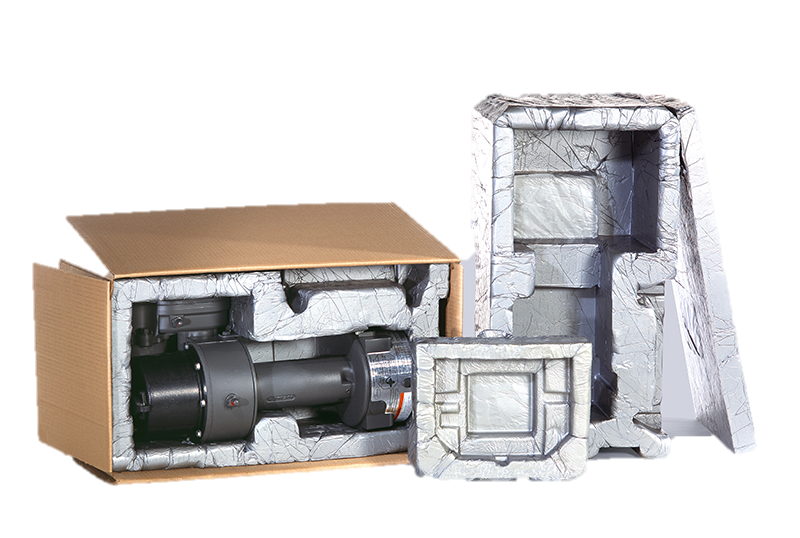

Foam thickness is not the only energy absorbing consideration. For heavier objects or with shipping conditions where great shocks are anticipated, higher density and/or thicker polyurethane foam materials may be appropriate. Since higher density foam absorbs energy efficiently, there may be opportunities to optimize packaging space and reduce overall shipping size.

This foam is versatile, provides excellent cushioning and can be fabricated to meet your specifications. The method tends to be one of the cost-effective types of protective packaging in the industry. Foam In Place is not to be confused with flexible or memory foams, because while most urethane chemical foams result in flexible packaging, Foam In Place utilizes a unique mixing process that results in a solid chemical composition. In addition, this foam can be form and shaped easily for bracing, supporting and wrapping objects.

Principle of packaging in ImPol 110:

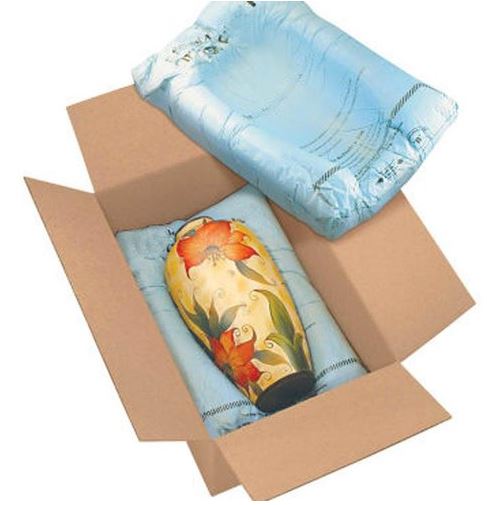

- PUR foam (2 component, ImPol 110 and ImIso 370) injected into special bags (commonly high density polyethylene (HDPE) bag or film) and forms in place that is why it is called Foam-In-Place

- Once mixed together, the mixture flows around the product and fills the void space in the cardboard box in which the product is inserted in mere seconds. The operation happens at the room temperature.

- ImPol 110 polyurethane foam will increase its volume after application by up to 200 times the volume of the original liquid

Scopes of characteristics are:

- ImPol 110 polyurethane foam guarantees the creation of perfect fillings with various shapes for a wide range of products.

- Customer receives the product undamaged during transport and handling, professionally packed in a light weight package. In other words, with the foam being put in place to protect items, there is a lower likelihood of it being damaged because the fragile item has no room to move.

- The created fittings are then reusable (the product can be unloaded and inserted)

- The method is used in the packaging of glass, porcelain, fine-art objects, antiques, musical instruments, sanitary ware, computers, sensitive appliances, furniture, and sets of fragile goods

In conclusion, it has to be noted that one of the biggest advantages of Foam-In-Place is its ability to be customized. Because the chemical reaction forms around the desired product, every application is completely different from the last. So, companies who have a variety of different products or product lines with inconsistent packaging requirements can seriously benefit from Foam-In-Place technology! On the other hand, it is also useful for shock sensitive chemicals, which require special protection.

If you put certain foam materials around a product with a sharp edge and it drops, the edge will cut right through. Foam-In-Place morphs into a hard protective case that sharp-edged products won’t break through. Consequently, products with sharp edges can also gain from adopting Foam-In-Place technology. It has to be mentioned that it’s an economical packaging method, which dramatically reduces the costs of packaging materials.