Table of contents

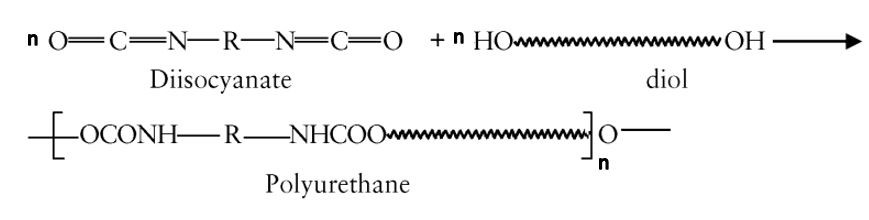

The first urethane was synthesized, as early as 1849 by Wurtz. The work of Wurtz demonstrated the preparation of monoisocyanates and the subsequent formation of urethanes and substituted urea linkages by reaction of the isocyanate group with a primary alcohol and a secondary amine, respectively. Thereafter, in 1937 in Germany, Dr. Otto Bayer was attempting to synthesize polymer fibers to compete with nylon and that’s when he succeeded synthesizing the first polyurethane, by the reaction of a diisocyanate with a polyester having two terminal hydroxyl groups (called polyester diol). In fact, Bayer invented a new method for the synthesis of macromolecular compounds; the polyaddition reaction (which is a special case of polycondensation), is also known as step polymerization. The reaction of diisocyanate with diol is represented below:

In 1940, the first polyurethane elastomers were successfully developed. These elastomers are a class of polyurethane materials whose physical characteristics were similar to that of rubber. During the second world war, these new materials became a cheaper alternative to rubber, which at the time was rare and expensive and also used as a coating to protect other common materials such as metals and wood.

The 1953, the first commercial production of polyurethane foam began in the US. which was a rigid foam and used for insulation and three years later, more flexible and cheaper foams were introduced. The foams were produced in a two-step process in which the polyether polyols were capped by reaction with excess diisocyanate in the first step and then reacted with water and diisocyanate in the second step. In 1958 and 1959, silicone surfactants and tin catalysts were developed that allowed the production of polyurethane foams in a one-step process and decreased the final price of foam. During the 1960s, semirigid polyurethane foams found application in automotive interior safety parts. In 1969, Bayer Company used reaction injection molding (RIM) technique to manufacture an all-plastic car, in this process, the reactants were mixed and then injected into a mold.

Nowadays, polyurethanes have been evolved and they are among the most important class of specialty polymers. They can be used for production of coatings, fibers and thermoplastics. Its versatility is the reason for the widespread popularity, it means that by carefully choosing the components the resultant polymer can be made soft enough to make furniture more comfortable and durable enough to use in tires. In other words, since polyurethanes can have a wide variety of properties, it is also used in many different applications. Furthermore, polyurethane foams have the advantage that they can cure at room temperature and that all formulation components are liquids at room temperature.

Although his work was a major breakthrough at the time, at first, this polymer was considered useless. Therefore, studying, improving and developing polyurethane’s components continuously and even optimizing formulations according to the needs of customers, follows seriously as one of the main goals of imen polymer chemie.