Table of contents

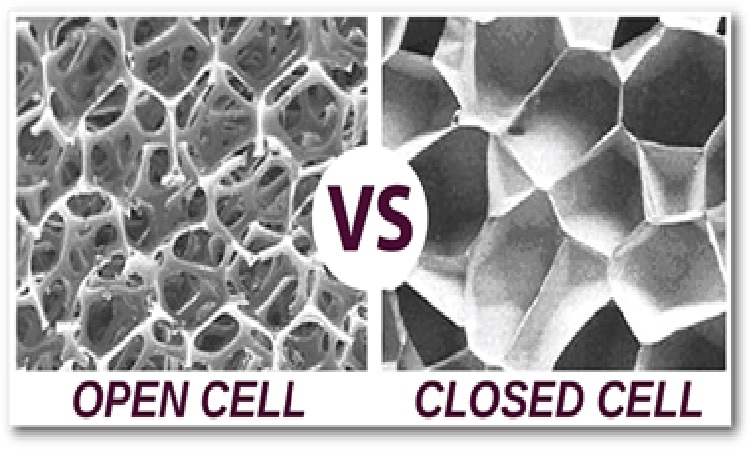

Their properties are categorized based on the foam structure. The foam has two types of structure:

(1) Open-cell structure (2) Closed-cell structure. Open-cell structured foam is as soft as like a cushion. The cell walls, or surfaces of the bubbles, are broken up and is filled up with air that fills up all the spaces in the material. This makes the foam soft or weak, and its feel is like that of a soft toy rubber ball. The insulation value of this foam is related to the insulation value of the calm air inside the matrix of broken cells. The densities of open-cell foams are around 8_12 kg/m3. Closed-cell foam has density which is dependent on hardness. A normal, closed-cell insulation or flotation PU is having density somewhere between 32 and 48 kg/m3. Most of the cells or bubbles in the foam are not broken and they resemble soccer balls that are piled together in a compact configuration.

This makes the foam strong or rigid because the bubbles are strong enough to take a lot of pressure, like the inflated tires that hold the weight of an automobile. The cells are full of a special gas, selected to make the insulation value of the foam as high as possible. The advantages of the closed-cell foams as compared to open-cell foams are that they have higher strength, higher R-value, and greater resistance to the leakage of air or water vapor. The disadvantage of the closed-cell foams is that due to higher density their material requirement is more and they are not economical. Even though they have a better R-value, the cost per R is still higher than open-cell foam. The choice of foam is normally done based on the requirements for certain specific properties like strength, vapor control, and available space. Both the types of foams are commonly used in building applications. Some are used in very special applications based on their specific inherent properties.

Closed-Cell Foam Has Very High Resistance Toward Water Vapor Permeation

- This property is very helpful as it provides protection against moisture transport into the insulation with its related potential for condensation. Vapor that remains on the inside wall (the warm side) will not come in contact with cold surfaces where the dew point can be reached.

Closed-Cell Foam Resists Damages From Short-Term Wet Conditions

- PU foam does not get affected by roof leaks, foundation leaks, or condensation.

- They can be easily used up in masonry construction, and they very well resist damage caused by water penetration.

Binding Strength of Foam

- Foams will neither compress nor settle.

- Foams show strong adhesion to steel decks on flat roof structures.

Structural Advantages of Foams

- Foams can help to resist wind shear.

- Foams serve to reinforce exterior sheathing and windows.

- PU foams are used in structural panels and other composite structures.

Thermal Conductivity

The most important property of an insulating material is its insulation performance. The efficiency of the material is ranked by its low thermal conductivity or its high thermal resistance.

U-value is reciprocal of R(U51/R) for a given construction and is generally represented in W/(m2 _ K).

Thermal Conductivity of Rigid PU Foam (PUR)

The thermal conductivity of rigid PU foam (PUR) is dependent on:

- Gas used in cells

Owing to the high closed-cell content of rigid PU foam in which closed cells comprise more than 90%, the blowing agents remain in the insulating material for over a long period of time. Gas diffusion-tight facings reduce the cell gas exchange with the surrounding air.14

- Density

The amount of structural material increases with increase in density. This directly increases the share of heat conducted over the structural material. The increase in thermal conductivity is not directly proportional to the increase in density. The thermal conductivity of rigid PU foam changes little in the density range of 30_100 kg/m3.

- Temperature

The thermal conductivity of insulating materials decreases as temperature decreases. But as the temperature increases, on the other hand there is a minimal increase in thermal conductivity.

- Foam behavior in the presence of water and moisture

At a reference temperature of 25°C, the thermal conductivity of water is λ50.58 W/(m _ K). The thermal conductivity of the most common insulating materials ranges between 0.020 W/(m _ K) and 0.050 W/(m _ K). Also water absorption due to immersion in water leads to an increase in thermal conductivity. But, water absorption has only a small impact on the thermal conductivity of rigid PU foam because it shows very good resistance toward water vapor permeation.