Table of contents

Various types of insulation materials are available in the market. We take a close look at waterproofing insulation, thermal insulation, and acoustic insulation; each of them is essential for protecting modern structures against moisture, temperature fluctuations, and noise. We also discuss the best methods of building insulation, indicating the reason for the popularity of polyurethane systems that deliver high performance and sustainability.

You don’t have to be a builder to care about insulation; knowing the right type can help make any building more comfortable, energy-efficient, and protected.

What is building insulation?

Building insulation refers to any materials and techniques that are designed to control the transfer of heat, sound, and moisture through walls, roofs, floors, and other structural components of a building. In other words, with the help of building insulation (reducing heat flow, limiting noise transmission, and preventing water penetration), the energy efficiency of structures and comfort are enhanced, and subsequently energy consumption is reduced.

Therefore, today, insulating buildings is no longer optional; it’s essential. This also plays a significant role in lowering utility bills and achieving sustainability purposes. The right insulation system also protects building materials from temperature fluctuations and moisture damage, finally preserving property value. Various types of insulation materials are available; each of them has unique properties and applications. In the below sections, we will talk about different types of building insulation, their applications, technical features, and how they help improve building performance.

After sales service

For price inquiries and purchasing liquid polyurethane for polyurethane foam production, please contact Imen Polymer Chemie Company.

Different types of building insulation

In general, there are three primary types of insulation for buildings: acoustic, thermal, and waterproofing insulation. Each has its own unique characteristics and, as a result, serves different performance purposes. In the following sections, we will discuss these differences in detail.

1. Waterproofing insulation for buildings

Protecting buildings from water inrushes, which can result in mold growth, structural damage, and decreased thermal performance, requires waterproofing insulation. This kind of insulation is often used on exterior walls, roofs, basements, and other places that are exposed to moisture. Modern waterproofing insulation solutions regularly rely on closed-cell polyurethane foam systems because of their excellent water resistance and low water absorption rate. Closed-cell polyurethane foams, which are produced from high-quality raw materials, create a dense, impermeable layer that prevents water entry while adding structural strength.

There are also waterproofing insulation materials that can be applied, so the choice depends on project requirements such as expected water pressure, substrate conditions, and installation methods. In addition to preventing water from entering, good waterproofing insulation helps keep the building energy-efficient by stopping moisture from damaging other insulation materials.

2. Thermal insulation for buildings

Suitable thermal insulation helps keep indoor temperatures stable during different seasons. By reducing how much heat passes in or out, it makes indoor spaces more comfortable and uses less energy for heating and cooling. This causes lower energy bills and less harm to the environment.

Insulation is usually added to walls, roofs, floors, and pipes to stop heat from escaping or entering. There are different materials like fiberglass, foam boards, or cellulose that can be used. Moreover, choosing the right one matters; it’s also important to install insulation properly so that heat doesn’t find other ways to pass through. Also, with the help of R-value, you can find out how well the insulation blocks heat and how eco-friendly the material is.

Polyurethane rigid foam stands out as a highly efficient thermal insulation material. With a low thermal conductivity (lambda value), rigid polyurethane foam can achieve high insulation performance with thinner layers compared to traditional materials like fiberglass or expanded polystyrene. This advantage makes it especially suitable for applications where space optimization is of great importance.

As building standards get stricter, better and smarter insulation solutions are being developed. It can be said that good insulation makes buildings more energy-efficient, helps the planet, and creates healthier and more comfortable places to live. Thermal insulation, in addition to reducing heating and cooling energy consumption, prevents condensation on cold surfaces, thereby protecting structures from moisture damage. The technical specifications of thermal insulation materials vary depending on density, thickness, and manufacturing process.

3. Acoustic insulation for buildings

The role of acoustic insulation is to reduce unwanted noise, whether it’s coming from outside the building or traveling between rooms and floors inside. By controlling sound transmission, this type of insulation creates quieter, more peaceful spaces. That means more privacy at home, better concentration at work, and greater comfort in places like hotels or hospitals, where noise levels directly affect people’s health.

Different materials can be used to reduce noise, each with its own strengths. For example, open-cell polyurethane foam is highly effective at absorbing sound. Due to its porous structure, it can trap sound waves and prevent them from escaping the room. Other common options include mineral wool and recycled cellulose, which are also known for their noise-dampening abilities.

But choosing the right material isn’t the only thing that matters. The success of acoustic insulation also depends on smart design and proper installation. It’s important to think about where the noise is coming from (it affects how well the insulation performs) and what type of sound it is. Meaning that the choice of insulation should also match the type of noise you want to block. Heavy and dense materials are better at stopping deep sounds, like traffic or loud machines. On the other hand, softer and lighter materials work well for blocking deep sounds, such as voices or ringing phones.

Also, remember that for the design and installation of acoustic insulation, you must consider factors such as sound frequency, noise source location, and the plan of a building’s structure. High-density insulation materials typically perform better in blocking low-frequency sounds, while lightweight porous materials are effective against high-frequency noises.

The best methods of building insulation

As mentioned just before, choosing the best insulation method depends on several factors, including the building’s structural design, budget, and environmental conditions. In the following, the two main methods for building insulation are discussed (according to the fact that polyurethane is the best insulating material).

- Spray polyurethane foam (SPF)

SPF is a versatile material widely used in insulation applications, specifically in the construction industry, due to its unique properties. SPF is created by combining two main liquid components, isocyanate and polyol.

As they are mixed together, they start reacting and forming a solid foam. This sprayed foam expands quickly as soon as it is applied. SPF fills gaps and crevices perfectly, therefore providing an effective air barrier. Its exceptional thermal insulation properties help reduce energy consumption by maintaining consistent indoor temperatures, making it an environmentally friendly choice (the less energy wasted, the less harm to the environment). Furthermore, SPF exhibits excellent soundproofing properties, which can enhance the acoustic comfort of buildings. Another significant advantage of this material is its resistance to moisture, which helps prevent the growth of mold and mildew, contributing to healthier indoor air quality.

For the insulating process, the presence of skilled professionals is necessary who can apply the foam properly. Keep in mind that incorrect application can lead to issues such as uneven surfaces or insufficient insulation. But, when it is applied correctly, SPF can remarkably increase the energy efficiency and durability of structures (specifically, thermal insulation spray foam polyurethane with its rigid structure adds extra strength to the buildings).

Overall, SPF is somehow an innovative solution for achieving great insulation and energy performance in residential and commercial buildings. It is applied directly onto surfaces where it expands and hardens, forming a seamless, airtight, and moisture-resistant barrier. Depending on the project’s needs, SPF can be applied in two main forms:

- Closed-cell foam is denser and has higher R-values; it can be used for both a thermal and vapor barrier.

- Open-cell foam is lighter and acts better as sound insulation due to its ability to absorb noise waves.

In summary, SPF is a powerful and efficient solution that combines thermal, acoustic, and moisture insulation in one application.

- Insulation panels and boards

- Insulation panels and boards

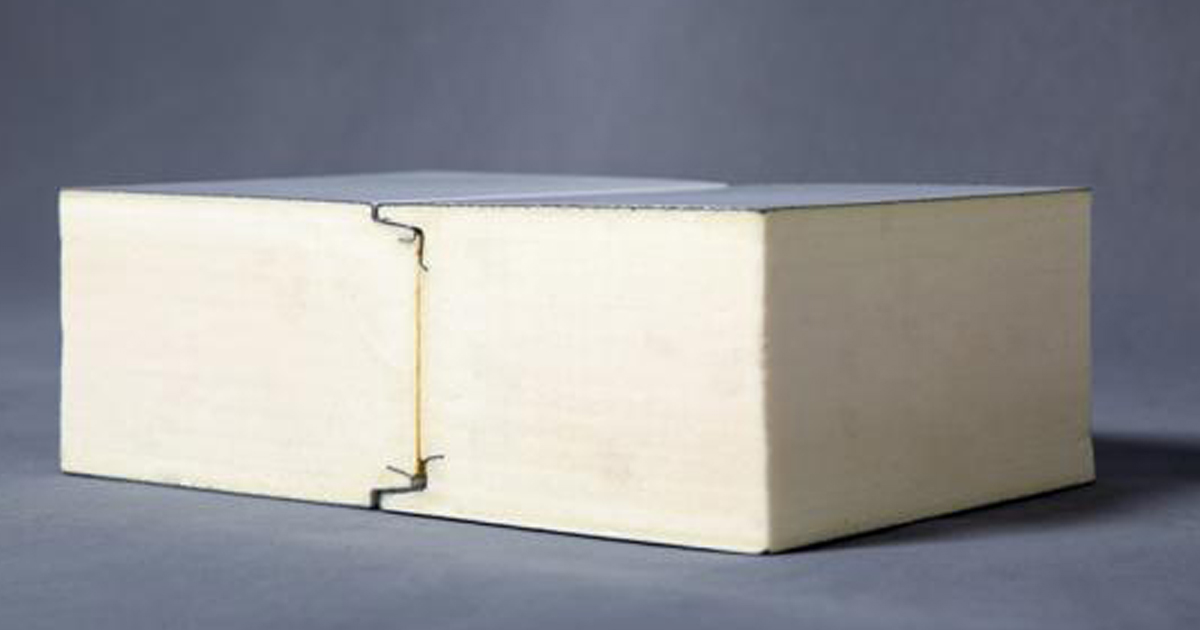

The second major method includes the use of prefabricated rigid insulation boards, which are widely used in modern construction, particularly for projects that require fast, clean, and efficient installation.

There are different insulation panels/boards on the market. The most common and effective ones are particularly based on thermal resistance and made of polyurethane and polyisocyanurate (PIR). These rigid polyurethane foam boards are cut into various standardized sizes and thicknesses. Therefore, they are ready for quick installation on walls, roofs, and floors. These panels combine high thermal performance with structural reinforcement so, they are ideal for large projects that need to be completed in a short time.

Polyurethane Products

Additional considerations when selecting building insulation

There are also some other considerations you’d better keep in mind while deciding on the right material for building insulation, such as the following:

- Environmental impact: One key consideration when selecting insulation materials is their environmental impact. Choosing high-quality and durable insulation with strong thermal resistance minimizes energy loss, which helps reduce greenhouse gas emissions. Additionally, long-lasting materials maintain their performance over time and don’t require frequent replacement, resulting in less material waste and a lower overall impact on the environment.

- Fire resistance: For building insulation, fire resistance is of great importance (this property directly affects the building’s safety). Polyurethane insulation materials can be formulated with fire retardants to meet international standards. They are available in various fire-resistance grades according to DIN 4102 (B1 and/or B2); this allows builders to select the appropriate formulation based on the specific fire safety requirements of each project.

- Durability and compressive strength: Choosing high-quality materials with long-term durability is always a concern, especially in areas exposed to mechanical stress like floors. Good insulation should resist early degradation, maintain its thermal performance over time, and offer suitable compressive strength to withstand loads. These materials are also less likely to attract pests. To ensure these benefits, it’s important to purchase from a reputable supplier that offers tested and certified products.

- Ease of installation: Some insulation types are easier and quicker to install. For example, prefabricated boards—boards with simple surfaces—save time. On the other hand, SPF does a great job when there are hard-to-reach areas or irregular shapes. Also, in projects with limited space, choosing the right insulation material becomes even more important.

- Cost: When choosing insulation, both initial and long-term costs matter. Some materials have a higher price at first but offer better energy savings and durability; this will lead to reduced future expenses. Other insulation materials might be cheaper at first glance, but they lead to higher utility bills and could need earlier replacement. As a result, balancing cost with performance helps ensure smart investment.

Moreover, selecting the right type of insulation depends on the building’s design, climate, and the performance goals of the project. As an example, colder climates typically need higher R-values (a thicker material or the one with higher efficiency).

Conclusion

Effective insulation is an important factor in making a building energy-efficient. From thermal and acoustic control to moisture protection, each type of insulation plays a key role in improving indoor comfort, safety, and long-term performance. By choosing the right materials and buying from trusted suppliers, construction professionals can achieve reliable results tailored to the specific needs of each project. Polyurethane insulation materials, due to their high performance and superior properties, are always a smart solution for durable and sustainable building insulation. When insulation is done right, it’s not just about saving energy; it’s about creating healthier, longer-lasting, and more efficient spaces.