Table of contents

Pigment dispersions (pastes) should always be used when pigmenting polyurethane resin rather than pigment powder because the rigorous milling and mixing process during manufacture ensures that the tiny pigment particles are fully dispersed into a small amount of carrier polyurethane, getting the very most from their color. When a dispersion is then added to the bulk of the polyurethane (PU) resin it blends in easily, ensuring that the pigment is thoroughly mixed through the resin (rather than staying in lumps).

color pastes comprise well-dispersed pigments/colors combined with polyester polyol and reactive hydroxyl groups, and are easily mixed into polyurethane systems. They are characterized by extremely high color intensity, bright color, appropriate viscosity and good flow properties. As a result, the choice between dry pigment and a pre-dispersed supply (color paste) form should not be made on price alone.

In fact, color pastes can be applied to interior coloring of PU materials without changing their structure or strength, while it can be designed in a way to substantially delaying or hiding the process of yellowing.

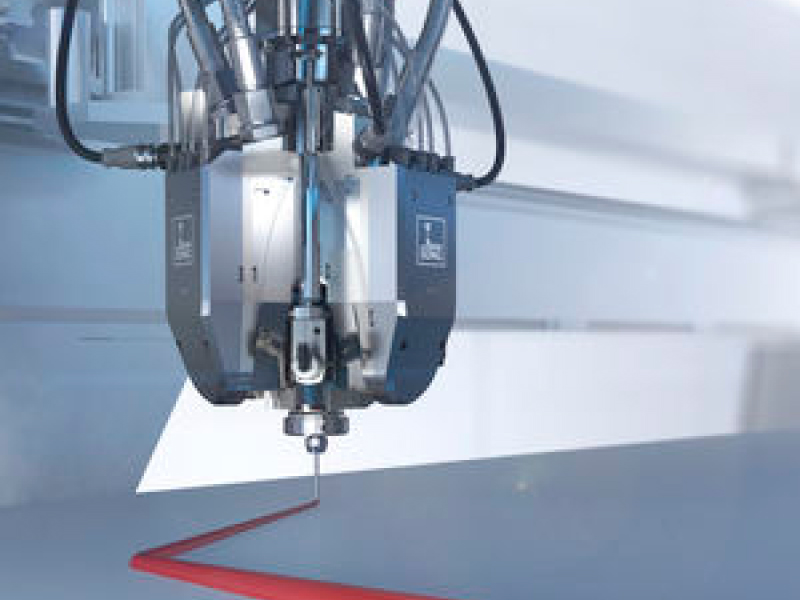

They can come with different viscosity required by customers without affecting their color expressiveness. Usually, small batch hand-mixing operations choose higher viscosity pastes for easier weighing and handling, while when metering pumps are used lower viscosity pumpable pastes are preferred. The tendency for pigments to settle increases the lower the viscosity. Therefore, stirring the paste before use at the pump, is highly recommended.

Advantages of color pastes in PU systems

- Good compatibility with various polyols

- Easy and optimal pigment dispersion

- Wide range of pigments

- Very good storage stability

- Desirable coloring effect

- Bright and uniform color

- Decrease in consumption compered to pigments

Main application fields

- Footwear

- Flooring

- Adhesives and Sealants

- Automotive interiors

- Furniture industry

- Foams for insulation and sealing

- Packaging foams

- Soft toys

- Integral skin foams

Imen Polymer Chemie Co. color pastes for polyurethane systems

Imen Polymer Chemie Co. has successfully designed color pastes for polyurethane foam systems in various colors (white, black, orange, pink, and red); also, they can be provided according to customer’s demand in a wide range of colors and there is possibility of designing UV resistant pastes. Formulas can be provided to maximize pigment content and reduce adding proportion by customers.

Features of the product in Imen Polymer Chemie Co.

- Solvent- or phthalate-free

- No problems of migration

- Easy dispersion

- Convenient processing viscosity

- Not impair the physical properties of polyurethane system even at high concentration

- The storage life of about 6 months (at 15-30)

- Resistant to the temperatures which occur during polyaddition

In conclusion, polyurethane color paste of high quality is manufactured for specialized applications by using pigments and other polymeric raw materials. Specialized applications are where the product is subjected to be used without any cover such as, car air filter, shoe sole, automotive interiors, foam in place gaskets, packaging foam and toys.

Based on the choice of the carrier, the customer can ensure that physical properties of the final product remain unchanged at any level of the pigment loading. It has to be noted that, to get desired color characteristics high color intensity pigment pastes with low loading can be achieved.

For more information feel free to contact us.