Table of contents

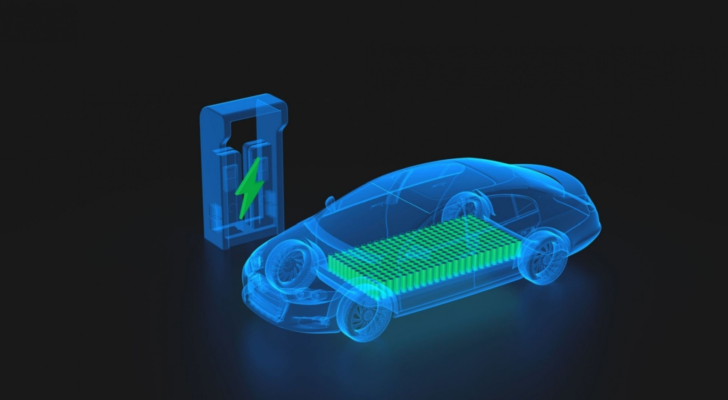

Polyurethane battery covers play a critical role in the electric vehicle (EV) industry, enhancing both the performance and safety of batteries. As EVs have gain a lot of attention in the automotive sector, the demand for high-quality, durable materials to protect batteries has grown significantly. Polyurethane coatings have emerged as a leading choice in this field due to their unique properties, including light weight and exceptional durability.

The rising importance of polyurethane battery coatings in EV

The shift towards environmentally friendly transportation has increased the need for energy efficiency and reduced greenhouse gas emissions. Lightweight parts have become a central trend in the automotive industry. Polyurethane battery covers, as vital components of EV batteries, contribute to this effort with their advanced performance and unique advantages.

One of the standout benefits of polyurethane covers is their electrical insulation properties, which shield batteries from thermal and electrical shocks. This ensures battery stability and minimizes risks associated with high temperatures or unauthorized voltage spikes, making polyurethane an indispensable material in modern battery technology.

Advantages of polyurethane battery covers

Polyurethane offers a range of high-performance features, making it an ideal material for battery coatings; these include the following:

- Elasticity and durability: Exceptional flexibility and resistance to wear and tear.

- Chemical and corrosion resistance: Protection against harsh environments.

- Electrical insulation: Protect internal components against electrical and thermal damage.

- Sealing capabilities: Prevents electrolyte leakage, enhancing battery safety and longevity.

Additionally, polyurethane coatings demonstrate outstanding weather resistance, maintaining stability across extreme temperatures, environmental conditions, and humidity. This reliability is crucial for batteries exposed to outdoor or harsh environments, ensuring EVs equipped with polyurethane-coated batteries perform reliably in any climate.

Polyurethane also excels at absorbing shocks and reducing vibrations, effectively enhance battery lifespan by minimizing physical stress during operation.

Lightweight Design and Cost Efficiency

Polyurethane’s exceptional processability makes it highly adaptable. Techniques like injection molding and compression molding simplify manufacturing, significantly reducing production costs and increasing efficiency. Customizable with various additives, polyurethane can be tailored to improve flame resistance, UV protection, and other specific requirements.

One key advantage is its contribution to reduce EVs weight. Research based on a sample survey of Chinese passenger vehicles reveals that reducing vehicle weight by only 10% can increase driving range by 5.5%. Since battery weight accounts for 20-30% of a typical EV’s total weight, designing lightweight polyurethane battery covers directly enhances driving range and lowers costs.

In other words, reducing the weight of these covers can lead to the overall reduction of the car’s weight and thus increase the car’s range. This feature is very important for electric vehicle manufacturers, who are looking to increase efficiency and reduce energy consumption.

Conclusion

The application of polyurethane in battery covers has become increasingly vital in modern battery technology, particularly in EVs and energy storage systems. As material technologies advance, the performance of polyurethane battery covers will continue to improve, offering exciting opportunities for growth in the battery industry.

With their superior mechanical, safety, and economic properties, polyurethane battery covers are among the best solutions for enhancing the performance and lifespan of EV batteries. As polyurethane innovations progress, their role in the automotive and energy sectors becomes even more prominent.