Table of contents

Polyurethane, a versatile performer in 3D printing

Polyurethanes are a family of polymers that can be engineered to display a wide range of mechanical, thermal, and chemical properties. This adaptability allows manufacturers to adjust a material’s hardness, flexibility, or durability to match specific application needs. In 3D printing, this is especially valuable for projects that require both high dimensional accuracy and specific performance characteristics, whether it’s elasticity for impact absorption, rigidity for structural support, or resistance to harsh chemicals.

Because polyurethane formulations can be tailored for different 3D printing techniques such as stereolithography (SLA), digital light processing (DLP), or material jetting, they provide advantages like:

- Customizable hardness: You can make it very soft or very hard, depending on the need.

- Excellent adhesion to substrates: This improves print accuracy and reducing layer misalignment.

- Chemical and heat resistance: Enabling long-term performance in tough conditions.

- Design flexibility: Allowing resin formulations to be optimized for individual projects (you can have custom design).

How spray-foam-based 3D printing works

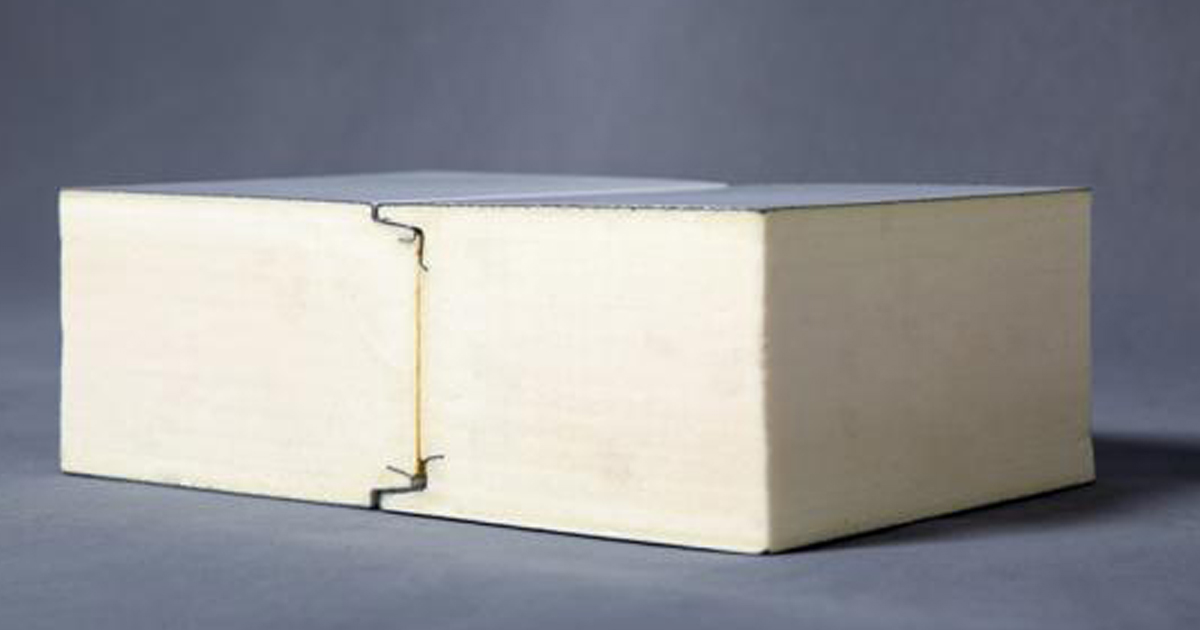

Traditional 3D printers use solid plastic wires (filaments) or liquid resins. Spray foam printing is different. It uses a special two-part polyurethane mixture that is sprayed out through a nozzle. This nozzle can be attached to a robotic arm or other automated system that moves with great accuracy.

The foam is sprayed in thin layers. Each layer quickly hardens before the next one is applied. By controlling the spray speed, angle, layer thickness, and timing, complex shapes can be created much faster than with regular 3D printing.

Compared to other resins like epoxy, polyurethane can be made less brittle and more flexible. It also sticks better to different surfaces, which is very helpful for printing unusual shapes.

Benefits of using polyurethane foam in 3D printing

Manufacturers and designers like polyurethane foam because it combines strength, durability, and flexibility. Some of its most valuable benefits include:

1. Impact and compression resistance: parts can withstand high mechanical stress without cracking or deforming.

2. Enhanced durability: better resistance to chemicals, moisture, and heat compared to many conventional resins.

3. Compatibility with multiple 3D printing methods: including DLP, SLA, and certain thermoplastic polyurethane (TPU) FDM systems.

4. Fully customizable properties: formulation can be changed to adjust curing time, surface texture, or mechanical performance.

Special features of 3D-printing-grade polyurethane

Polyurethane made for 3D printing has specific qualities, such as the following:

- Controlled viscosity for even deposition

- Controlled hardening time for accurate details

- Strong bonding to print surfaces

- UV stability for decorative or outdoor applications

- Adjustable hardness from very soft (Shore A) to very hard (Shore D)

This combination makes polyurethane foam a high-performance candidate for projects that need both strong structural parts and decorative designs.

The role of robotics and automation in foam-based 3D printing

Using robots in spray foam printing brings high accuracy and faster production. Robotic arms can follow digital designs exactly, applying foam in precise amounts and positions. This ensures parts match the design perfectly and have an even surface.

Automation also means the process can run without breaks, repeat the same task many times without mistakes, and work in dangerous or hard-to-reach areas. This is especially helpful for large projects with tight deadlines.

Polyurethane Products

Industrial applications of spray polyurethane foam in 3D printing

This method is great for creating large or complex shapes. It’s used to make:

- Large models and prototypes

- Decorative pieces with fine details

- Stage and exhibition structures

- Oversized advertising displays

- Architectural models and full-scale mock-ups

Compared to traditional 3D printing, spray foam printing is:

- Faster: Layers harden quickly, so projects finish sooner.

- More efficient: Uses only the material needed. Lower material waste through controlled deposition is possible.

- Scalable: Can make very large objects without huge, expensive printers.

Conclusion

Spray polyurethane foam 3D printing, especially with robotic systems, is a somehow new and exciting way to make strong, large, and detailed parts. It’s quick, accurate, and works for both industrial and creative projects. For innovators in architecture, design, and industrial manufacturing, it’s not just a new material, it’s a new way of thinking about what’s possible.