Table of contents

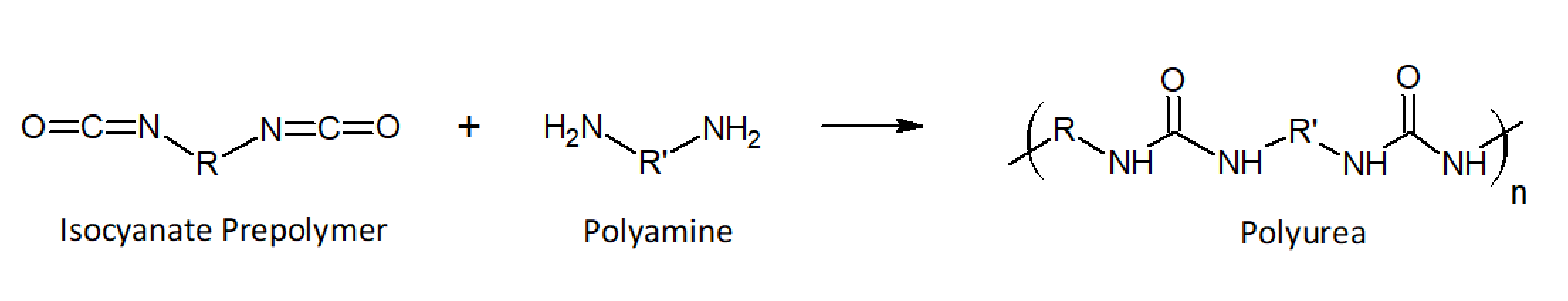

Polyurea is a substance derived from step-growth polymerization, which is the result of the reaction of polyamines with polyisocyanates; the mentioned reaction is illustrated in the following:

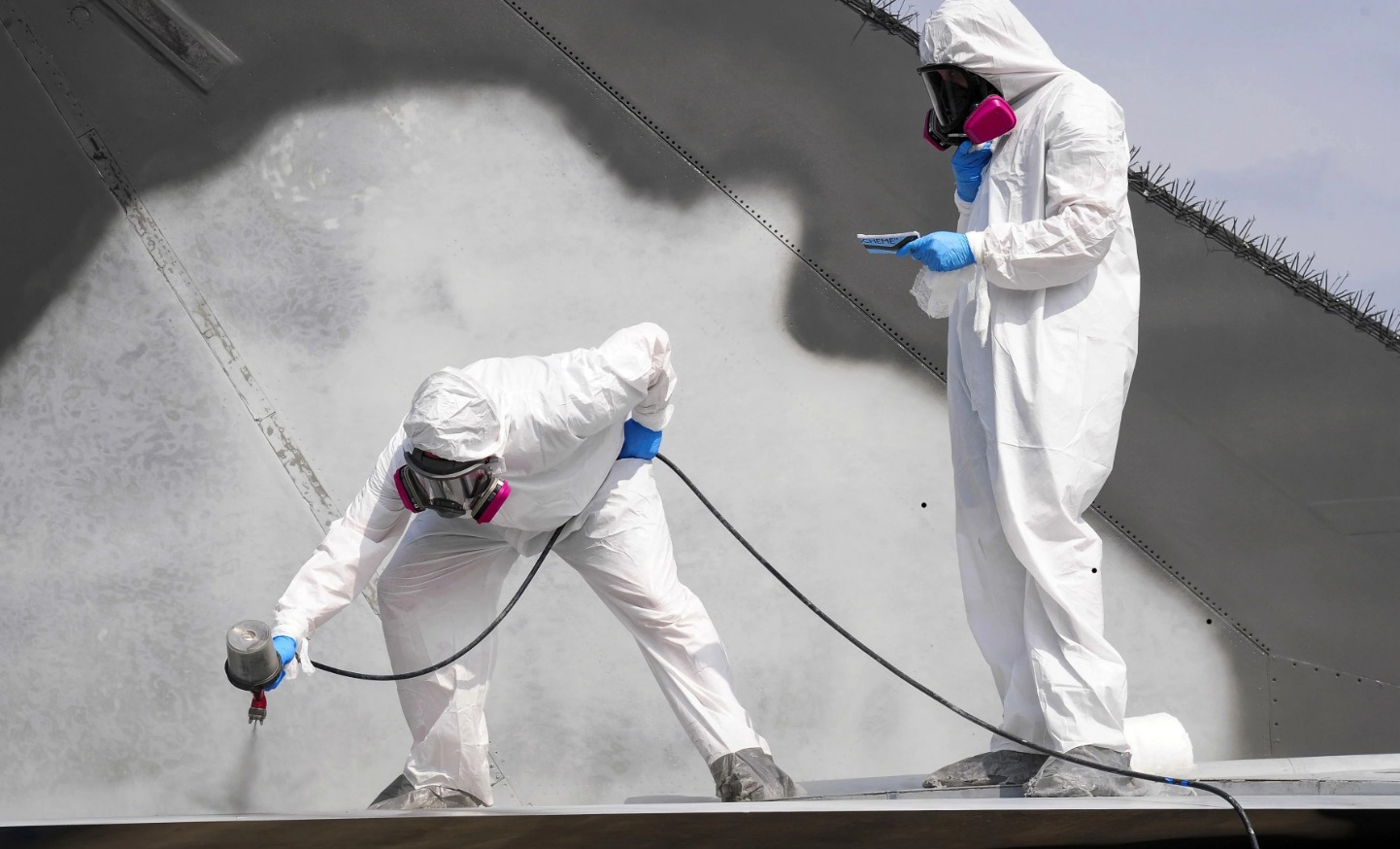

It is a waterproofing material that is often used in industrial and commercial settings to protect surfaces from water damage. It is applied as a liquid coating, which then quickly cures to form a durable, waterproof barrier. This can be used for waterproofing roofs, foundations, decks, and other surfaces. Also used to seal concrete structures, such as swimming pools, water tanks and retaining walls.

The adaptability and adhesion of the polyurea allow use in almost any application requirement waterproofing, coating and/or protection can include: waterproofing and corrosion protection on steel, concrete and many other supports.

It adheres tenaciously to a variety of different substrates (concrete, metals, wood and more) without primers and in a wide range of temperature and humidity environments. In other words, it can be applied even on wet surfaces.

Advantages and properties of polyurea coating

- Very fast setting (within few seconds up to typically 2 to 5 minutes depending upon the formulation)

- Excellent strength and durability (make it an ideal option for waterproofing surfaces that are exposed to harsh conditions.)

- Excellent chemical resistance (suitable option for waterproofing surfaces in industrial settings)

- Flexibility (can be applied to a wide range of surfaces and is suitable for use on both smooth and irregular surfaces)

- Elongation (high elongation properties which allow it to move with the substrate and avoid cracking)

- Temperature resistance (resist high and low temperatures and maintain its flexibility over a wide range of temperatures)

Types of polyurea

Depending on polyurea chemical structure, it could be of two types: aliphatic or aromatic.

- The aromatic polyurea is more tenacious and not resists UV exposure, causing some discoloration and loss of shine, which is not recommended for applications “face side”.

- On the contrary, aliphatic polyurea is resistant to UV radiation and it is excellent as a finish coat, because of its raw materials high costs, it makes it a polyurea of higher price range.

Applications for Polyurea Coatings

- Automotive industry

The auto industry has used polyurea coatings for more than three decades. It can be said that it developed in the late 1980s for the automotive industry, this material is now used in a wide array of applications. The coating is popular because of its impact resistance and other mechanical properties, moreover, because of its corrosion- and abrasion-resistant characteristics.

- Pipelines, pumps and irrigation systems

Polyurea provides corrosion and abrasion protection of pipelines that carrying abrasive and corrosive materials. It is used as a pump coating to reduce cavitation and erosion, and to improve pump output. It is also used to line aquaculture tanks and ponds, and for canal repairs and leakage proofing.

- Defense and security sectors

Due to their proven impact resistance, ability to absorb explosive energy, durability and quick setting features, polyurea coatings and linings easily find use in the defense and security sectors. As a military equipment coating, polyurea can contract and expand with changes in ambient temperature and form a moisture tight seal. Coatings will be free of scratches, dents and abrasion damage, all while ensuring an attractive glossy appearance. Coating military buildings with polyurea can minimize damage due to bomb blasts.

- Healthcare

In a hospital environment, ideally the floor and wall coverings will be resistant to viruses and bacteria because there is a constant risk of patients acquiring a secondary infection. Cracks, crevices and scratches on the floor can cause moisture seepage and spread dangerous diseases.

Polyurea coatings seal cracks and prevent scratches that might otherwise occur due to frequent scrubbing, thus minimizing the risk of bacterial propagation. These coatings can help maintain sterile conditions in surgical areas, intensive care units and neonatal care units.

- Concrete structures and bridges

Due to polyurea properties (as mentioned just before), it is used for the initial coating. Also, polyurea’s structure (molecular chain) makes it to have a high durability. This is the secret of its suitability in construction and other fields. Consequently, it can prevent the collapse of concrete structures.

To sum up, polyurea protects wooden, concrete and steel surfaces and structures from abrasion and corrosion damage. It can help preserve a deteriorating concrete structure and help repair and keep canals intact. It resists scratches, chemicals, oils and salts in commercial and industrial floor applications. It can also preserve boats and other vessels by providing protection from cracking and deterioration. As a matter of fact, pure polyurea does not react with water making it the best waterproofing material.