Table of contents

The importance of pipe insulation

Pipe insulation is becoming a must in industries where thermal regulation and energy conservation are so important. Whether in oil and gas pipelines, chilled water systems, or industrial plants, uninsulated or poorly insulated pipes can lead to significant energy losses, condensation problems, corrosion, and even safety risks.

Rigid polyurethane foam is a polymeric material that has low thermal conductivity and closed-cell structure. It has become a preferred choice for pipe insulation in tough environments. The foam offers exceptional insulation performance while it is lightweight, chemically stable, and highly durable. Consequently, polyurethane foam is widely used in both above-ground and underground piping systems.

What makes an insulation foam the best for pipes?

There are several factors you’d better to consider when deciding on choosing the best pipe insulation foam. They are as follows:

- Thermal resistance (R-value): The material must minimize heat transfer effectively. In other words, it must have a high R-value to resist heat flow.

- Moisture resistance: It should prevent condensation and avoid water absorption. The closed cell structure of rigid PU foam resist water penetration easily.

- Mechanical strength: The foam must withstand physical stress and compression. It has to be mentioned that high mechanical strength leads to a longer lifespan.

- Chemical resistance: Compatibility with pipeline contents and external chemicals is crucial. In simpler terms, the insulation must have great chemical resistance, especially to environmental factors.

- Ease of application and maintenance: A reliable insulation system should be easy to install and require minimal maintenance (generally, easier installation can lead to cost savings).

Polyurethane excels in all these areas, which is why it is widely known as the best insulation foam for pipelines in industrial and commercial sectors.

After sales service

For price inquiries and purchasing liquid polyurethane for polyurethane foam production, please contact Imen Polymer Chemie Company.

Polyurethane vs. other pipe insulation materials

In this section, we are going to compare polyurethane insulation material to other commonly used pipe insulation materials like polyethylene, elastomeric foam, fiberglass, and mineral wool. By the end, you will see the reason behind its popularity.

- Polyurethane vs. fiberglass: While fiberglass has good thermal resistance, it is more fragile, prone to moisture absorption, and less effective in maintaining a consistent R-value over time (fiberglass will sag over time and the provided R-value will be lowered). Polyurethane’s closed-cell structure makes it significantly more resistant to water penetration and thermal bridging.

- Polyurethane vs. polyethylene: Polyethylene is lightweight and flexible, making it suitable for residential use. However, it cannot withstand high temperatures or pressure changes as effectively as polyurethane, limiting its application in industrial setting.

- Polyurethane vs. elastomeric foam: Elastomeric foam is flexible and resists condensation, but its thermal performance is inferior to that of polyurethane. In long-term energy savings, polyurethane offers better insulation with thinner layers.

- Polyurethane vs. mineral wool: Mineral wool is fire-resistant and cost-effective but doesn’t have the structural rigidity and moisture barrier qualities of polyurethane. Its fibrous structure can also break down over time, especially in humid environments.

These comparisons indicate the clear advantages of polyurethane over alternative insulation materials, but the real question is, what makes polyurethane the preferred choice in challenging, real-world applications? Its advantages go well beyond technical specifications, ranging from exceptional energy efficiency to long-term durability and environmental compatibility.

We’ll cover the distinct advantages of polyurethane pipe insulation in more detail in the sections that follow, as well as the reasons it remains the industry standard. Discover why it’s the best option for modern facilities by reading more.

Advantages of polyurethane pipe insulation

Polyurethane pipe insulation benefits are various, but the main important ones are stated below.

- Exceptional thermal insulation: With one of the lowest thermal conductivity values (~0.020–0.025 W/m·K), polyurethane foam minimizes heat loss or gain, reducing energy consumption through applications.

- Moisture and vapor resistance: The closed-cell structure of polyurethane foam acts as a vapor barrier, it prevents condensation and corrosion under insulation, which is a major issue in industrial pipelines.

- Structural integrity: Once applied, polyurethane foam forms a rigid, durable shell around the pipe, enhancing protection against mechanical damage and environmental stress (the insulation will not sag over time).

- Wide operating temperature range: Polyurethane insulation performs well in extreme temperature environments, typically between -180°C to +120°C, this makes it ideal for both cryogenic and hot fluid systems.

- Fast and reliable installation: Spray or injection-application methods allow for seamless coverage, even around complex pipe geometries. It adheres strongly to the pipe surface, reducing the need for additional adhesives or mechanical fasteners.

- Lightweight: Polyurethane foam adds minimal weight to piping systems, which is an advantage in large-scale construction or transportation projects.

- Maintenance and long-term performance: One of the strengths of polyurethane insulation is its minimal maintenance requirements. Due to its rigidity and moisture resistance, polyurethane maintains its physical properties over time. In fact, when properly installed, polyurethane insulation can last for decades without significant degradation.

Applications of polyurethane pipe insulation in different industries

Because of its excellent thermal performance, durability, and resistance to moisture and chemicals, polyurethane pipe insulation is used in a wide range of industries, including:

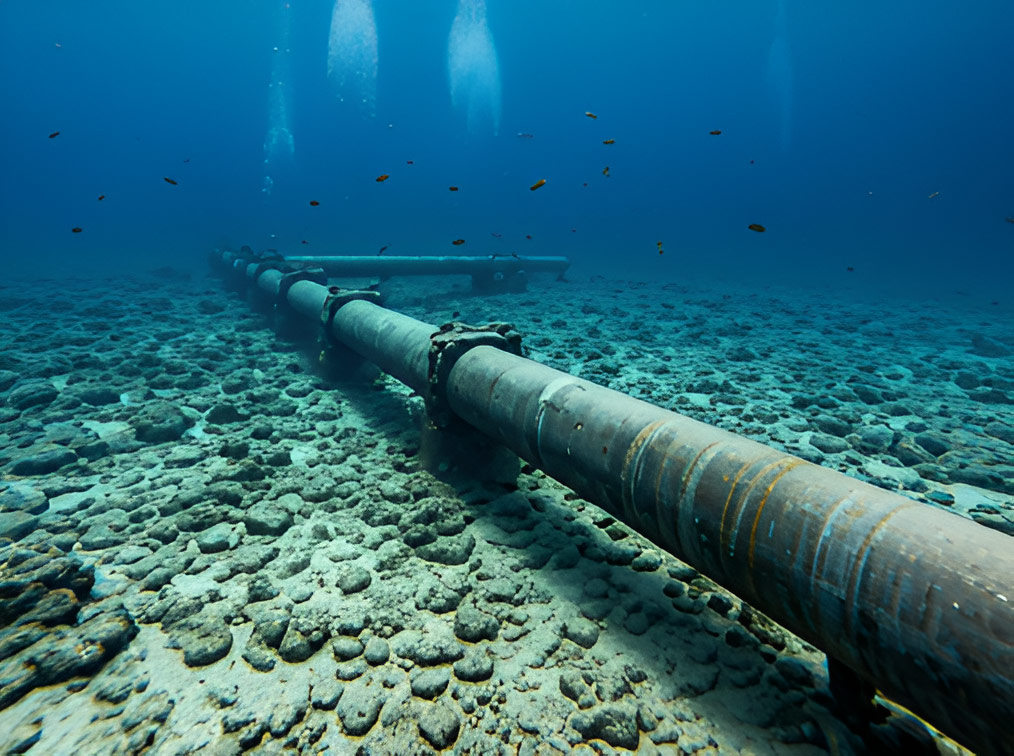

- Oil and gas pipelines

Whether onshore or offshore, polyurethane insulation helps keep the fluids inside pipelines at the right temperature. This prevents issues like wax buildup or hydrate formation, which can block the flow.

- District heating and cooling systems

In systems that carry hot or chilled water across long distances, polyurethane keeps the temperature stable and reduces energy loss, making the entire network more efficient.

- Chemical and petrochemical plants

Polyurethane’s chemical resistance and thermal stability make it a reliable choice for insulating process lines. It other words, it protects pipes carrying aggressive media under high temperatures and pressure.

- Food and beverage processing

Cleanliness and temperature control are essential in food processing. Polyurethane insulation resists moisture and helps maintain precise conditions in piping systems.

- Cold storage systems

In commercial buildings and refrigeration units, polyurethane insulation helps lower energy consumption and improve system performance by minimizing heat transfer.

How to choose the right polyurethane system for pipe insulation

Selecting the right polyurethane formulation for pipe insulation isn’t just about choosing a product, it’s about finding a solution that fits the specific requirements of your project. Different applications demand different physical, thermal, and mechanical properties. The most critical factors you should evaluate when selecting a polyurethane system including:

- Operating environment: Will the insulation be exposed to direct sunlight, high humidity, chemical vapors, or extreme temperatures? Outdoor and above-ground installations require polyurethane systems with excellent UV resistance, while underground applications demand high mechanical strength, water impermeability, and long-term thermal stability. In contrast, indoor or controlled environments may allow for lighter formulations.

- Thermal insulation performance: The core purpose of pipe insulation is to reduce heat transfer. You should choose a polyurethane system with a low thermal conductivity to ensure maximum energy efficiency, especially for hot or chilled pipelines.

- Surface application type (exposed or embedded): Whether the pipe is above ground (exposed) or embedded (underground or inside walls) affects the type of insulation system required. Exposed pipes may need additional mechanical or UV protection, while embedded systems should be more compression-resistant to handle soil pressure or construction loads.

- Mechanical strength and compression resistance: For applications such as buried pipelines or areas subject to physical stress, a higher-density polyurethane foam offers better structural stability and impact resistance.

- Moisture and vapor resistance: In humid or coastal regions, closed-cell polyurethane system with excellent water barrier properties can prevent condensation and corrosion under insulation.

- Installation method: The way insulation is applied plays a major role in system selection. Spray-applied foam is ideal for complex shapes or on-site installations. Pour-in-place systems work well for pipe joints or fittings, while pre-insulated pipe sections are commonly used in district heating and industrial infrastructure for faster deployment.

- Fire performance (if required): In facilities where fire safety is a concern, using flame-retardant polyol systems is recommended. These systems can be formulated to meet various international fire resistance standards.

Environmental benefits of polyurethane insulation

Today, sustainability is a key factor in material selection. Polyurethane contributes to green building practices in several ways:

- Energy efficiency: Superior insulation reduces energy consumption in heating and cooling systems.

- Durability: Long service life minimizes the need for replacements and reduces waste.

- Reduced material usage: High insulation performance allows for thinner applications compared to other materials.

Moreover, modern polyurethane systems can be formulated with low-GWP (Global Warming Potential) blowing agents, supporting compliance with international environmental standards.

Common installation methods for polyurethane pipe insulation

There are several methods for applying polyurethane insulation to pipes:

- Spray application

This method involves spraying two-component polyurethane directly onto the pipe surface on-site. It’s especially suitable for large, complex pipe networks or retrofitting existing systems. Spray foam creates a seamless layer of insulation that adheres tightly to the surface, minimizing thermal bridges and gaps. It’s commonly used in industrial facilities, refineries, and process plants where quick, flexible application is needed.

- Pour-in-place/pre-insulated pipe systems

One of the most efficient and widely used pipe insulation methods in industrial applications is the pre-insulated pipes, also known as pipe-in-pipe insulation. In this method, a smaller carrier pipe (typically made of steel, copper, or PEX) is inserted into a larger protective casing, usually a high-density polyethylene (HDPE) or metal outer pipe. The space between the two pipes is then injected with rigid polyurethane foam, forming a strong, uniform, and high-performance insulation layer.

- Pre-fabricated pipe systems

This method uses pre-fabricated half shells for insulation, commonly called split pipe insulation/urethane insulation half shells. These are produced in standard sizes and manually assembled around the pipe during installation. Once installed, the segments are sealed with adhesives or vapor barriers and may be covered with metal or plastic jacketing. This is a convenient solution for maintenance work, pipe repairs, or small-scale projects where spray or injection is not practical.

Why choose Imen Polymer Chemie for polyurethane pipe insulation raw materials?

At Imen Polymer Chemie, we provide tailored polyurethane raw material systems for pipe insulation, carefully engineered based on your operating conditions, performance targets, and installation preferences. Whether you’re insulating pipelines in an oil refinery, a district heating system, or a cold-storage facility, we help you select the right formulation to deliver reliable and long-lasting results. Our formulations are tested for superior thermal and mechanical performance, ease of processing, and environmental safety.

We don’t sell the foam itself, but we provide the essential building blocks that allow foam producers and pipeline contractors to manufacture high-quality insulation systems. With in-depth technical support, product customization, and export capabilities, we are proud to be a trusted partner for businesses across the region and beyond.

Conclusion

In a competitive industrial landscape where energy efficiency, performance, and sustainability matter, polyurethane foam clearly stands out as the best pipe insulation solution. Its low thermal conductivity, moisture resistance, and long-term durability make it the insulation material of choice for pipelines in nearly every sector.

Whether you’re working on a new district heating project, upgrading oil and gas pipelines, or insulating industrial process lines, choosing the right polyurethane raw material is key to long-term success. Imen Polymer Chemie is here to support you with reliable polyurethane systems engineered for excellence.

Contact our team today to find the ideal polyurethane solution tailored to your pipe insulation project, and take the first step toward excellent performance and energy savings.