Table of contents

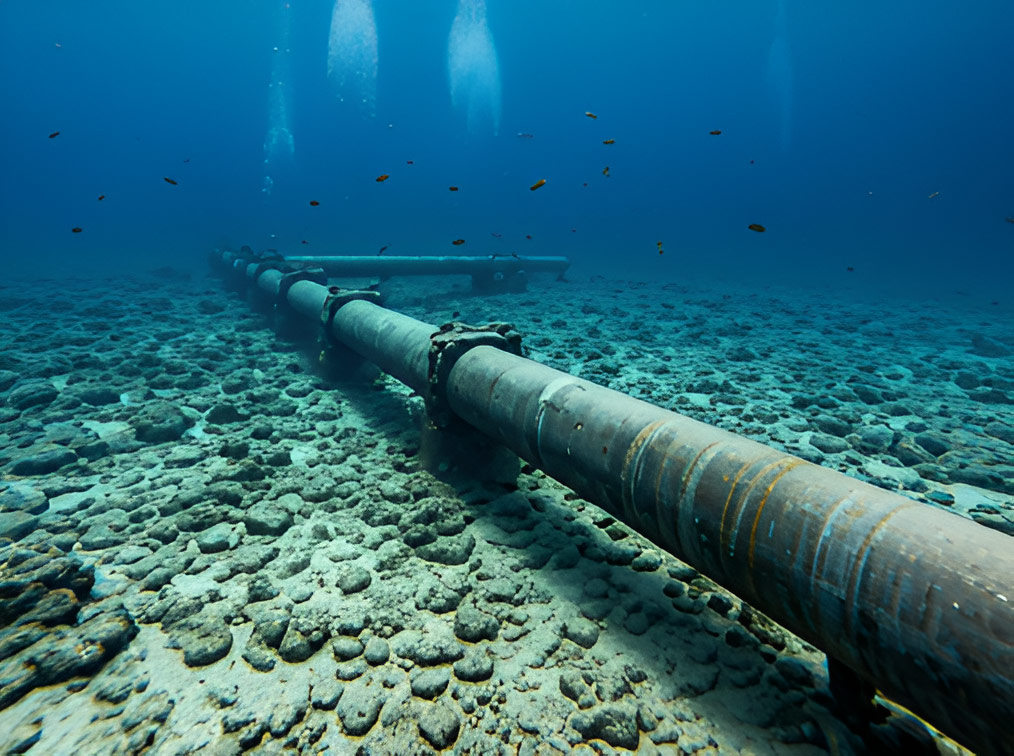

In fact, effective insulation protects pipelines from rapid heat loss, prevents flow problems such as hydrate formation, and ensures stable long-term operation. In other words, it extends the service life of the pipeline all of which are essential for safe and economical offshore operations. As a result, this article explains what subsea pipeline insulation is, the materials commonly used, and why polyurethane has become the preferred solution for deep-sea environments.

What is subsea pipeline insulation and why is it essential?

Subsea pipeline insulation refers to a thermal barrier applied to pipelines transporting hydrocarbons under water. Its main function is to keep the temperature of the transported fluid above its critical threshold, preventing the formation of hydrates or wax deposits that can disrupt flow or block the pipeline entirely.

In offshore production, repairing cost is very high (operational downtime can reach millions of dollars per day), so pipe insulation with suitable material is of great importance. Without effective insulation, the temperature of the transported fluid drops quickly as it moves through cold seawater, especially in deep areas below 1,000 meters where temperatures are close to freezing. Such rapid cooling can cause serious operational issues, which is why insulation is considered a core element of flow assurance in subsea engineering.

It has to mentioned that the role of subsea pipeline insulation is beyond just controlling the temperature. A strong and stable insulation system also offers mechanical protection against external forces, pressure changes, and possible contact with fishing gear or underwater tools. In addition, effective insulation improves energy efficiency by reducing heat loss over long distances, which lowers the need for additional heating. When insulation is properly selected and applied, it helps the pipeline operate safely, minimizes the risk of blockages, and reduces maintenance costs. Because of these advantages, insulation plays an important role in protecting offshore pipelines and keeping them reliable for many years.

Types of subsea pipeline insulation systems

Subsea pipeline insulation systems are generally classified into three main categories based on how the insulation interacts with seawater and how it is integrated into the pipeline structure: pipe-in-pipe (dry insulation), wet insulation, and flexible insulation systems (this classification is widely accepted in offshore engineering standards and flow assurance design practices).

- Pipe-in-pipe (dry Insulation) systems consist of two concentric pipes, where the inner pipe transports the hydrocarbon fluid and the outer pipe provides mechanical protection. The insulation material is placed in the annular space between the two pipes and is fully isolated from direct contact with seawater. Because the insulation remains dry, these systems offer the highest thermal performance and are especially suitable for deep-water and ultra-deep-water applications. Pipe-in-pipe systems are commonly used for long-distance subsea flowlines where maintaining fluid temperature over extended lengths is critical. Although they involve higher manufacturing and installation costs, their superior thermal efficiency and stable performance over time often justify their use in demanding offshore environments.

- Wet insulation systems are applied directly to the external surface of a single steel pipeline and remain in continuous contact with seawater throughout their service life (that’s why it is also known as direct insulation). These systems rely on insulation materials that can withstand hydrostatic pressure while maintaining low thermal conductivity under wet conditions. Wet insulation is widely used for subsea flowlines, jumpers, and spools due to its simpler installation and lower overall cost compared to pipe-in-pipe solutions. While wet insulation generally provides lower thermal performance than dry systems, modern polymer-based materials—especially polyurethane—have significantly improved resistance to water absorption and pressure-induced degradation, making wet insulation a reliable choice for many subsea projects.

- Flexible insulation systems are specifically designed for flexible pipes and dynamic subsea components. Unlike rigid pipeline insulation, flexible systems must adapt continuous movement, bending, and dynamic loads caused by waves, currents, and platform motion. These insulation layers are typically integrated into the flexible pipe structure and are engineered to keep thermal performance without cracking or dividing into layers. Flexible insulation plays an important role in ensuring flow assurance in areas where rigid pipelines cannot be used, particularly in deep-water developments with complex seabed geometry or floating production systems.

Ultimately, the choice of insulation system depends on operational conditions, fluid type, depth, and pressure requirements, and polyurethane is applied in various subsea insulation systems because it can be tailored to meet different performance needs.

Best materials for subsea pipeline insulation

The materials used for subsea insulation must tolerate harsh underwater conditions, low temperatures, and chemical exposure while maintaining stable thermal performance over time. Common insulation materials include syntactic foams, polyurethane foams, polypropylene foams, elastomeric coatings, and advanced composite systems. Syntactic foam is often applied in deepwater projects because it can retain its insulating properties at great depths. It is made of microscopic hollow spheres embedded in a polymer matrix, which provides both strength and low weight. However, the complex production process and high cost of these microspheres limit its widespread use.

Polypropylene and polyurethane foams remain the most commonly used polymer-based insulation materials. Polypropylene offers good mechanical durability and cost efficiency for shallow-water applications, but its thermal performance decreases as water depth increases. Rigid polyurethane foam, in contrast, keeps stable insulation properties at significant depths due to its closed-cell structure, high compressive strength, and low water absorption.

Elastomeric coatings are also used in certain flexible pipeline segments, providing excellent subsea durability and resistance to mechanical deformation. In all cases, the performance of insulation materials is heavily influenced by their density, cell morphology, and long-term hydrolytic stability. High-quality raw materials, detailed formulation, and controlled manufacturing processes are therefore essential for producing reliable insulation systems capable of withstanding decades of underwater service.

Why polyurethane is the most effective choice for deep-sea pipeline insulation?

Polyurethane has become the industry standard for deep-sea pipeline insulation because of its exceptional mechanical and thermal stability under pressure. At depths exceeding several thousand meters, the hydrostatic force can exceed 300 bar, causing most foams to collapse or absorb water. Polyurethane systems designed for subsea applications maintain structural integrity due to their dense, cross-linked cellular structure and ability to resist compression without significant thermal degradation. This reliability is crucial for ensuring continuous thermal protection throughout the pipeline’s lifespan, even under repetitive thermal cycling and mechanical stress.

Another key advantage of polyurethane is its versatility in formulation. Manufacturers can customize density, thermal conductivity, and curing kinetics to match the exact requirements of each project. This adaptability allows polyurethane to perform effectively in a wide range of temperatures, pressures, and fluid compositions. Moreover, rigid polyurethane foam exhibits low water absorption, excellent adhesion to steel surfaces, and strong chemical resistance—properties that significantly reduce the risk of insulation failure in corrosive subsea environments. These characteristics make polyurethane a popular choice for insulation systems, for buoyancy modules, bend stiffeners, and other subsea components requiring long-term durability.

Purchase polyurethane raw materials for subsea pipe insulation

Selecting well-formulated polyurethane raw materials is necessary for ensuring the performance and longevity of subsea insulation systems. High-quality polyols and isocyanates allow manufacturers to achieve consistent density, mechanical strength, and closed-cell structure—all critical parameters in deep-water applications. Imen Polymer Chemie produces specialized polyurethane raw materials tailored for pipeline insulation, using advanced formulations that deliver stable thermal conductivity, superior pressure resistance, and long-term hydrolytic durability. These raw materials are designed to meet strict offshore industry requirements and provide exceptional curing stability during production.

Working with a trusted supplier ensures access to reliable materials and to technical support throughout the formulation and manufacturing process. Imen Polymer Chemie provides expert consultation to help customers refine foam density, optimize cure profiles, and adjust formulations for specific environmental and operational conditions. This comprehensive support reduces production risks and enhances final product performance. Offshore insulation projects need precision, and partnering with the right raw-material manufacturer ensures that operators can achieve consistent quality, long-term reliability, and operational cost-efficiency across their pipeline networks.

Conclusion

Subsea pipeline insulation is a critical engineering solution for maintaining operational safety, flow assurance, and energy efficiency in offshore oil and gas production. With increasing exploration in deep and ultra-deep waters, insulation materials must tolerate extreme pressures, low temperatures, and challenging environmental conditions while protecting valuable subsea infrastructure. Among available materials, polyurethane stands out as the most reliable and adaptable option due to its mechanical strength, low thermal conductivity, and long-term resistance to moisture and pressure.

For operators and manufacturers looking for high-performance raw materials to produce advanced insulation systems, Imen Polymer Chemie offers specialized polyurethane formulations engineered specifically for pipeline applications. By choosing the right materials and expert support, offshore developers can significantly improve pipeline integrity and ensure efficient, uninterrupted flow throughout the life of their subsea assets.