Table of contents

The search for the perfect thermal insulation for building floors requires finding the right balance between performance, durability, cost efficiency, and sustainability. This article will give you a clear, science-based overview of floor insulation, the materials commonly used, and the reasons polyurethane based systems perform better than many alternatives. Whether you are an engineer, architect, project manager, or insulation material buyer, this guide is designed to help you make better decisions for modern construction projects.

What is thermal insulation for building floors?

Thermal insulation for building floors includes materials or systems installed inside or beneath floor structures to reduce heat transfer between indoor spaces and the ground or other levels of a building. Floors can be a major source of heat loss during winter and heat gain during summer, especially in buildings built directly on the ground or located in regions with large temperature differences. Effective floor insulation helps maintain stable indoor temperatures and lowers the energy required for heating and cooling systems. In addition to improving thermal comfort, proper floor insulation helps buildings meet modern energy-efficiency regulations that focus on improving overall building performance.

Floor insulation works by limiting heat transfer through conduction, convection, and in some cases radiation. Compared to walls and roofs, floor insulation must tolerate higher mechanical loads, constant pressure, moisture exposure, and long-term use without losing performance. For this reason, choosing the right insulation material is especially important. A properly designed insulation system ensures long-term structural stability while keeping thermal performance. Since building floors support people, furniture, and equipment, insulation materials must have strong physical strength and long-term chemical stability.

Types of thermal insulation for building floors

A variety of insulation materials is used in building floors, each offering specific benefits depending on project conditions, budget limitations, and performance requirements. Common choices include extruded polystyrene (XPS), expanded polystyrene (EPS), mineral wool, fiberglass, cork, and polyurethane-based systems. XPS and EPS are popular mainly because of their relatively low cost and resistance to moisture; however, they have limitations in compressive strength and long-term dimensional stability. Mineral wool provides good fire resistance and sound insulation, but its sensitivity to moisture reduces its suitability for floor applications. Cork is an environmentally friendly material, but it is not ideal for areas exposed to heavy loads and may deform over time.

Polyurethane insulation, especially rigid polyurethane (PU) and polyisocyanurate (PIR) foam, is widely known as one of the highest-performing insulation solutions worldwide. These materials offer excellent compressive strength, very low thermal conductivity (compared to other alternatives), and strong adhesion, particularly when applied as spray systems. In modern construction, polyurethane-based insulation is highly preferred due to its high thermal efficiency, long service life, and flexibility in different floor designs. It is especially effective in commercial buildings, cold storage facilities, multi-level structures, industrial floors, and energy-efficient residential projects.

Key features of thermal insulation for building floors

Several key performance factors determine whether an insulation material is suitable for use in flooring systems or not. The most important of these is thermal conductivity, also known as the lambda value. Insulation materials used beneath floors must have very low thermal conductivity in order to effectively limit heat transfer. Materials with low lambda values play a major role in meeting building energy-efficiency standards and reducing long-term energy costs. For example, polyurethane insulation with its low thermal conductivity, is an ideal choice for applications that need high energy efficiency.

Compressive strength is another critical property of floor insulation materials. Floors are continuously exposed to loads from people, furniture, and heavy equipment, so the insulation layer must resist deformation under constant pressure. Materials with insufficient compressive strength may deform over time, leading to long-term floor settlement and reduced insulation performance. Moisture resistance is equally important, as floors especially those installed over concrete slabs or directly on the ground are often exposed to moisture. Water absorption can significantly reduce insulation efficiency and accelerate material degradation. That’s why moisture-resistant solutions are widely preferred for long-term performance and reliability in floor insulation applications.

The best thermal insulation for building floors

When evaluating the most effective thermal insulation for building floors, industry specialists focus on key performance factors such as thermal resistance, mechanical durability, moisture resistance, and service life. Numerous comparative studies indicate that polyurethane insulation—especially rigid polyurethane (PU) and polyisocyanurate (PIR) foam performs better than many alternative materials in almost every category. Its very low thermal conductivity provides excellent energy efficiency, while its high compressive strength allows it to withstand sustained structural loads.

Unlike mineral wool or fiber insulation, polyurethane does not sag, deform, or lose thickness over time, which makes it highly reliable for long-term use. In addition, the closed-cell structure of rigid polyurethane foam offers exceptional resistance to moisture. As mentioned just before, water absorption alters insulation performance negatively.

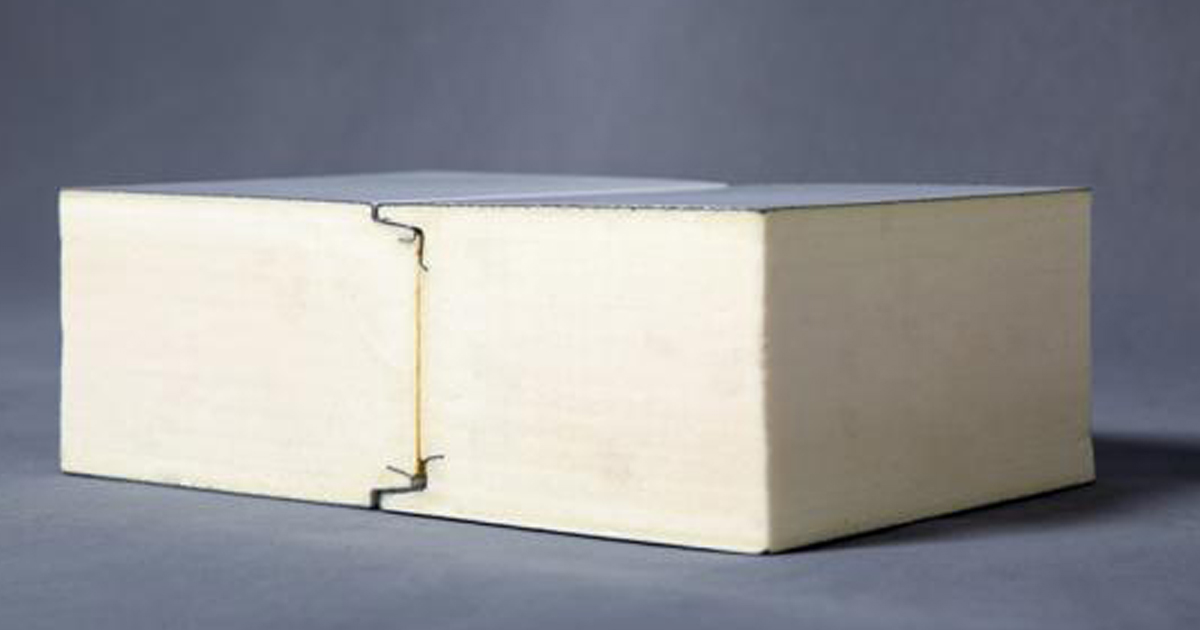

Polyurethane’s versatility further enhances its advantages: spray-applied systems create a continuous, seamless insulation layer over complex surfaces, while rigid polyurethane panels provide precision and uniformity for more standardized construction. For these reasons, polyurethane insulation is widely used in modern energy-efficient buildings and in projects that must meet strict energy standards.

Why should we use polyurethane thermal insulation?

Polyurethane is so popular due to its perfect thermal efficiency, which enables building designers to get high insulation performance with thinner layers compared to other materials. This results in more usable interior space and greater flexibility in architectural design. Because polyurethane has one of the lowest thermal conductivity values (typically about 0.025 W/m·K), it can achieve the same thermal resistance using significantly less material than EPS, XPS, or mineral wool. The material’s dimensional stability ensures that it keeps its shape, thickness, and thermal performance over years of use, even under pressure.

Moreover, polyurethane insulation enhances building durability. Its ability to bond strongly to substrates increases structural cohesion, reducing thermal bridging and improving the overall performance of the building envelope. Polyurethane is also resistant to mold, bacteria, and chemical degradation, which contributes to healthier indoor environments. In industrial or commercial settings, polyurethane-insulated floors help maintain consistent temperatures, reduce HVAC loads, and support operational efficiency. These benefits make polyurethane an especially valuable choice in countries with high energy costs or extreme temperature variations.

Purchase polyurethane materials for thermal insulation from Iran

Iran has become a regional hub for the production and supply of polyurethane raw materials, offering high-quality products that meet international standards. Buying polyurethane materials directly from specialized manufacturers in Iran allows buyers in the Middle East, Asia, and Europe to benefit from competitive pricing, consistent formulations, and reliable support services. Among the most reputable suppliers, Imen Polymer Chemie is recognized as a trusted manufacturer of polyurethane raw materials, offering specialized formulations tailored for thermal insulation applications in building floors. Our company provide engineered PU-based systems designed for rigid foam insulation with optimized thermal conductivity, compressive strength, and long-term stability.

As a knowledge-based producer with specialized experience in polyurethane technology, we offer more than just materials. Our technical team supports clients throughout the process—from selecting the proper formulation for a project to guiding optimal application methods. Whether you are sourcing materials for residential flooring, commercial buildings, cold storage facilities, or industrial insulation systems, purchasing from Imen Polymer Chemie ensures access to high-performance raw materials engineered specifically for insulation excellence. Iran’s growing expertise in polyurethane production, alongside the company’s commitment to quality and innovation, makes it an ideal supplier for international buyers looking for reliable materials for advanced thermal insulation systems.

Polyurethane Products

Conclusion

The best thermal insulation for building floors must combine low thermal conductivity, high compressive strength, moisture resistance, and long-term durability. While various materials exist in today’s market, polyurethane insulation consistently considered the most efficient, dependable, and versatile option for both residential and commercial construction. Its great thermal properties, mechanical resilience, and adaptability make it the top choice for modern energy-efficient buildings. For developers and distributors seeking high-quality polyurethane raw materials, Imen Polymer Chemie offers proven expertise, advanced formulations, and technical support that ensure the long-term success of insulation projects. Choosing the right thermal insulation today will significantly impact energy performance, structural reliability, and building comfort for decades to come—and polyurethane remains the material that brings excellence in every aspect.