Table of contents

Proper insulation of refrigerant and chilled water pipes plays a key role in system performance, energy consumption, durability, and overall comfort. When insulation is selected and applied correctly, it protects the pipes and also enhances the efficiency and reliability of the entire HVAC system.

This article gives a clear and practical explanation of air-conditioning pipe insulation, why it matters, what benefits it offers, which materials are commonly used, and how high-quality polyurethane raw materials help improve performance, save energy, and extend system lifespan.

What is air conditioner pipe insulation and why is it important?

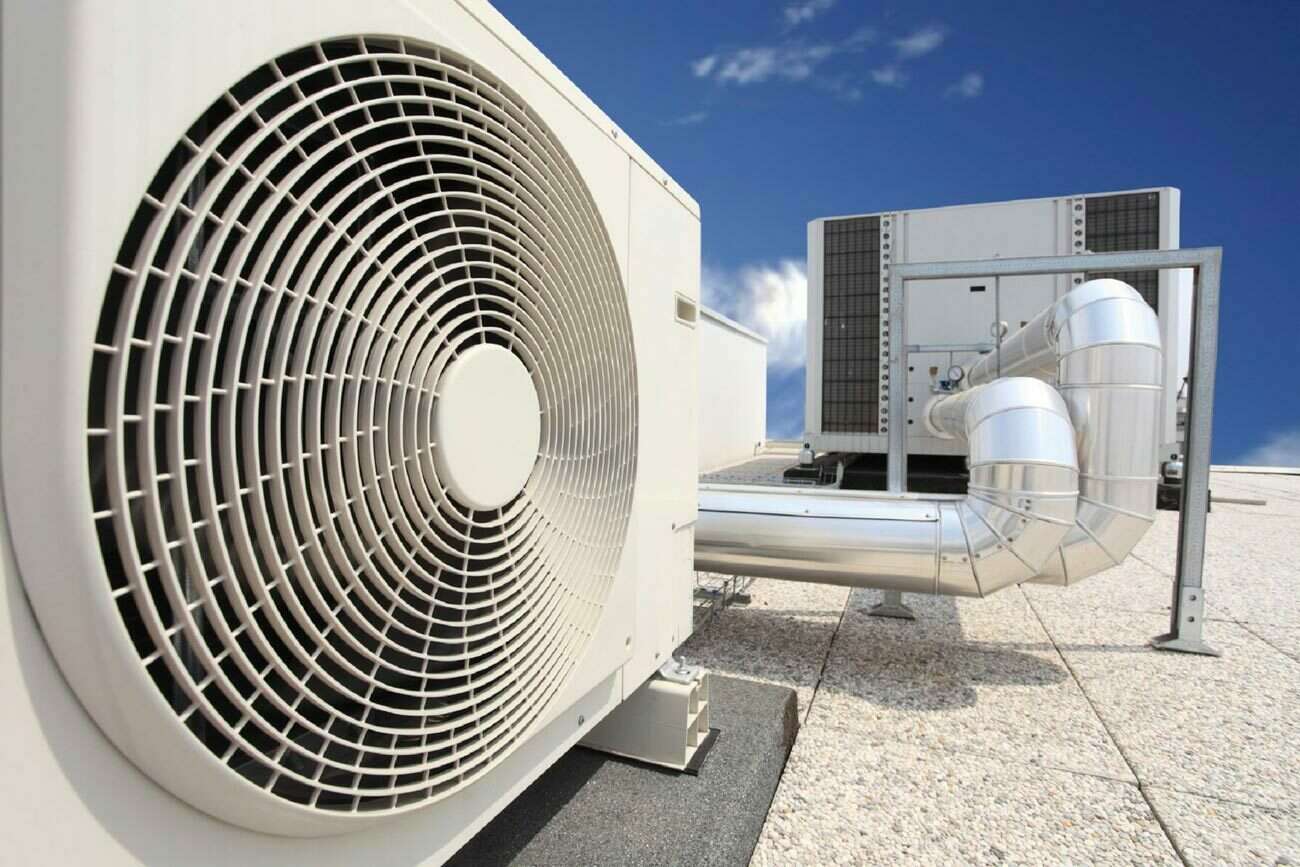

Air conditioner pipe insulation is the protective layer placed around the pipes that carry refrigerant or chilled water in an air conditioning system. These pipes often operate at temperatures very different from the surrounding air. Without insulation, they quickly absorb heat from the environment or lose cooling power along the way. Insulation helps keep the temperature inside the pipes stable so the system can do its job properly and deliver cooling where it is needed.

Another important reason for insulating AC pipes is moisture control. When cold pipes are exposed to warm, humid air, water can form on their surface. Over time, this moisture can cause rust, water damage, and even mold in nearby areas. Proper insulation keeps the pipe surface dry by reducing temperature differences and limiting moisture contact. For any air conditioning system that is expected to work efficiently and reliably, pipe insulation is a basic and necessary part of the design.

Benefits of proper air conditioner pipe insulation

When pipe insulation is done correctly, the results are easy to notice. The system cools more effectively because less energy is wasted along the pipes. This means the air conditioner does not need to work as hard to reach the desired temperature, which leads to lower electricity consumption and more consistent cooling performance, especially in larger buildings.

Proper insulation also helps protect the system over time. Pipes that are shielded from heat, moisture, and constant temperature changes are less likely to crack, corrode, or fail early. This reduces maintenance needs and unexpected repairs while helping the system last longer. In simple terms, air conditioner pipe insulation is not an extra feature, but a practical decision that improves comfort, reduces costs, and supports long-term system performance.

Types of insulation materials for AC pipes

Several materials are used to insulate air-conditioning pipes. Rubber insulation is common because it is flexible, easy to install, and helps block moisture. It is often used on refrigerant pipes, especially where pipes need to bend or fit into tight spaces. However, its performance can decrease over time, especially in hot or outdoor conditions.

Fiberglass is another insulation option and is mainly used for chilled water pipes in commercial buildings. It can reduce heat transfer, but it must be well sealed. If moisture enters the material, it loses much of its insulating ability.

Polyethylene foam is a lighter and cheaper option, but it does not insulate as well and is usually not suitable for high-performance air-conditioning systems.

Polyurethane (PU) foam is used when stronger and more effective insulation is needed. It has very good heat-blocking ability and resists moisture well, which helps keep pipes cold for longer and reduces energy loss. Also, spray polyurethane foam is widely used for insulating air conditioner pipes, especially in mechanical rooms and industrial HVAC systems where pipes, valves, and fittings have complex shapes. Unlike pre-formed insulation, sprayed polyurethane foam expands on contact, creating a continuous and tightly bonded insulation layer that eliminates gaps and thermal bridges. This makes it particularly effective for moisture control, energy efficiency, and long-term durability in demanding environments.

Best insulation material for air conditioner pipes

As just mentioned before, among the available insulation options, polyurethane-based insulation systems are known as one of the most effective and reliable solutions for insulating air-conditioning pipes. Polyurethane materials have very low heat transfer, which means they can keep cold or hot fluids at the desired temperature even when the insulation layer is not very thick. This is especially important in modern buildings where installation space around pipes is limited and designers need efficient insulation without increasing pipe size.

Besides strong thermal performance, rigid polyurethane foam insulation is durable and keeps its shape over time. Its closed-cell structure helps prevent water and moisture from entering the insulation, which greatly reduces condensation and protects pipes from corrosion. When properly formulated, polyurethane materials can also be adjusted to meet different needs, such as fire performance, density levels, and environmental requirements. Because of these advantages, polyurethane raw materials are widely used by manufacturers and contractors to produce high-performance and long-lasting insulation systems for air-conditioning pipes.

How air conditioner pipe insulation improves energy efficiency?

Energy efficiency in air-conditioning systems depends greatly on how well heat transfer is controlled during operation. When pipes are properly insulated, the cooled refrigerant or chilled water can travel through the system without picking up unwanted heat from the surrounding environment. This helps maintain the intended temperature difference and allows the system to deliver the required cooling using less energy.

Good insulation also helps reduce how often compressors turn on and off and limits sudden peak loads. With less heat loss, the system runs more smoothly and steadily, instead of constantly stopping and restarting, which wastes energy and puts extra stress on mechanical parts. Over time, this leads to lower electricity costs, less environmental impact, and better alignment with energy efficiency standards. From a sustainability point of view, insulating air-conditioning pipes is one of the easiest and most effective ways to improve overall HVAC performance.

Common problems caused by poor AC pipe insulation

Poor or improperly installed insulation can cause many practical problems in air-conditioning systems. One of the most common issues is condensation. When insulation is not effective, moisture forms on the pipe surface, which can damage the pipes and create conditions for mold and bacteria to grow. This can reduce indoor air quality and may lead to health concerns, especially in places like offices, shopping centers, and hospitals.

Another major problem is higher energy use caused by heat loss. Without proper insulation, the cooling effect weakens as it moves through the pipes, so the system has to run longer to reach the desired temperature. This puts extra strain on the equipment, increases maintenance costs, and shortens the system’s service life. These problems show why choosing the right insulation material and installing it correctly is essential for efficient air-conditioning performance.

Polyurethane materials for pipe insulation supplier from Iran

Iran has become as a significant producer of high-quality polyurethane raw materials for various industrial applications, including HVAC insulation systems. Imen Polymer Chemie is a specialized manufacturer and supplier of polyurethane raw materials designed for use in foams specially pipe insulation, coatings, and adhesive systems. Rather than producing finished insulation products, our company focuses on developing advanced polyurethane formulations that insulation manufacturers can use to produce high-performance solutions.

The polyurethane systems offered by our company are engineered to meet international standards in terms of thermal conductivity, density control, mechanical strength, and moisture resistance. With strong technical expertise and continuous research and development, we support our customers by providing tailored material solutions, technical consultation, and consistent product quality. For global markets looking for reliable suppliers of polyurethane raw materials for air conditioner pipe insulation, Iran-based manufacturers like Imen Polymer Chemie represent a competitive and technically capable option.

Conclusion

Air conditioner pipe insulation is a key factor in the overall performance of HVAC systems. Proper insulation helps reduce energy loss, maintain stable temperatures, and prevent condensation on pipe surfaces. It also supports smoother system operation and reduces stress on mechanical components. Choosing the right insulation material is important to ensure long-term reliability and durability. Polyurethane-based insulation is widely used in modern air-conditioning systems because it offers strong thermal insulation and good resistance to moisture. These advantages make it a practical solution for energy-efficient and long-lasting HVAC installations.