Table of contents

Features of polyurethane Plastofoam adhesive

Plastofoam adhesive is composed of polyol and isocyanate, which react chemically to create a stable and durable structure. Its key features include:

- High adhesion: It adheres effectively to various surfaces, including Styrofoam, metal, wood, glass, and stone, ensuring strong bonding between layers.

- Moisture and heat resistance: It maintains its effectiveness even in extreme environmental conditions like high humidity and elevated temperatures.

- Chemical Resistance: Able to withstand strong alkalis and acids.

- Optimized curing time: Formulated for appropriate curing times to streamline production processes, even in high-speed manufacturing lines.

- Fire resistance: Certain formulations are designed to possess fire-retardant properties.

- Long-term durability: It preserves its quality over time, prolonging the lifespan of products that using this adhesive.

Applications of polyurethane Plastofoam adhesive

Due to its adaptable characteristics, this adhesive is used in various applications, including:

- Construction: Bonding and insulating Plastofoam in walls, ceilings, and floors.

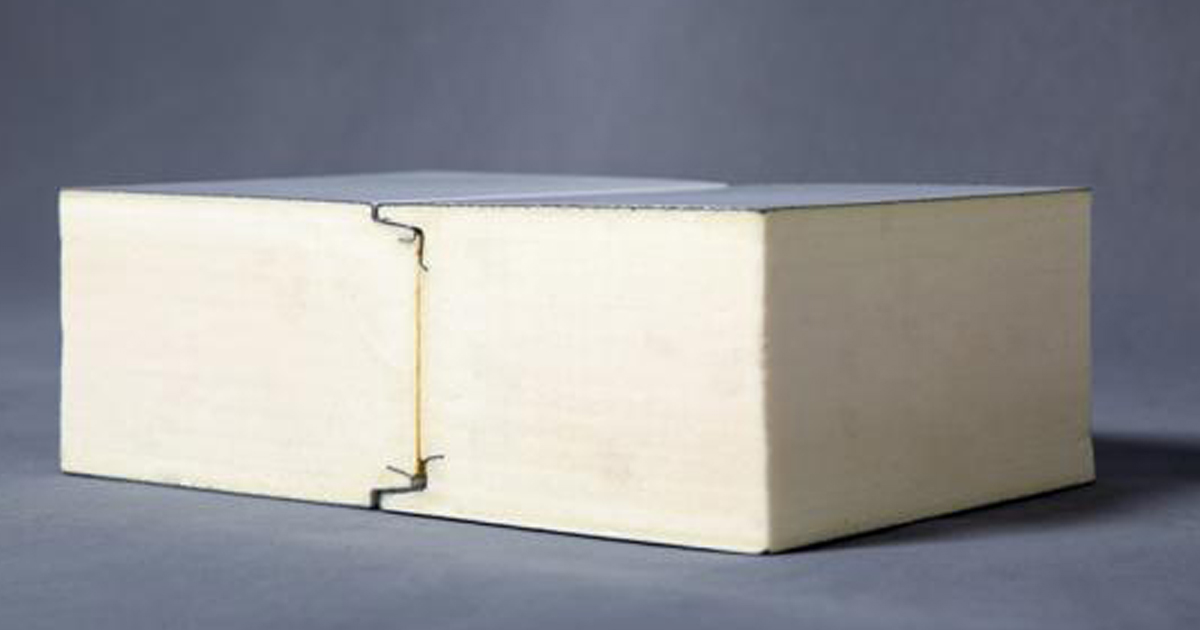

- Sandwich panels: Used in manufacturing thermal and acoustic insulation panels for containers, prefabricated rooms, and cold storage.

- Packaging industry: Connecting lightweight and fragile Styrofoam components.

- Decorative and model making: Bonding delicate pieces to create sturdy structures.

- Automotive industry: Manufacturing truck panels, especially for refrigerated vehicles.

- Door production: Used in doors with polystyrene foam cores and PVC covers.

Types of polyurethane Plastofoam adhesives

Polyurethane adhesives for polystyrene are available as one-component and two-component systems, which can be elastic or rigid depending on their formulation. One-component polyurethane adhesives are generally easier to use since they do not require mixing before application. On the other hand, two-component polyurethane adhesive systems are typically stronger and exhibit more desirable physical properties.

1. One-component polyurethane adhesives

In one-component adhesives, polyols and isocyanates (the two essential components) are pre-mixed to form a prepolymer that reacts with environmental moisture or heat to cure. This curing process begins when water is sprayed onto the adhesive surface or the sample is subjected to pressure and heat simultaneously.

- Moisture-curing one-component polyurethane adhesive:

These adhesives are commonly used for general-purpose applications both indoors and outdoors. They require moisture to cure and retain their elasticity after curing. Typical applications include glazing and construction.

When working with moisture-curing adhesives, it’s crucial to consider the adhesive’s working time. Once water contacts the adhesive surface, the reaction accelerates, and after a specific period, the curing process completes. Afterwards, the adhesive loses its ability to bond to new surfaces.

- Heat-Curing One-Component Polyurethane Adhesive:

Another type of one-component polyurethane adhesive cures when exposed to external heat. These adhesives create rigid bonds and are generally stronger than moisture-curing adhesives. However, they are not as strong as rigid two-component polyurethane adhesives. Therefore, one-component systems are often used in simpler assembly applications.

Heat-curing adhesives can process faster than moisture-curing adhesives since their drying time is controllable with heat. For rigid adhesives, thick layers should be avoided as curing begins from the outer surface, and thicker layers increase the risk of incomplete curing inside.

2. Two-Component Polyurethane Adhesives

In two-component adhesives, the main components are stored separately and react to form polyurethane bonds when mixed.

- Two-Component Polyurethane Adhesive Systems:

These adhesives can be elastic or rigid, depending on their chemical composition. Elastic two-component polyurethane adhesives are thermoplastic, meaning they can be reprocessed upon heating. Conversely, rigid two-component polyurethane adhesives are thermoset and cannot be reprocessed after curing.

Multi-component polyurethane adhesive systems allow for easier customization compared to one-component systems. As a result, these systems can offer enhanced physical properties and are suitable for use across various industries. Applications range from printed circuit boards to glazing and automotive interior decorations.

After sales service

For price inquiries and purchasing liquid polyurethane for polyurethane foam production, please contact Imen Polymer Chemie Company.

How to Use Polyurethane Plastofoam Adhesive

To achieve optimal results and high bonding strength, surface preparation and proper adhesive application are essential. Follow these steps carefully:

- Surface preparation:

Ensure the surface is clean and free of dust, grease, oil, or any contaminants that could hinder proper bonding. Use a clean cloth and appropriate cleaning solutions. For smooth or polished surfaces, light sanding can improve adhesion. After cleaning, ensure the surface is completely dry, as moisture can reduce adhesive performance.

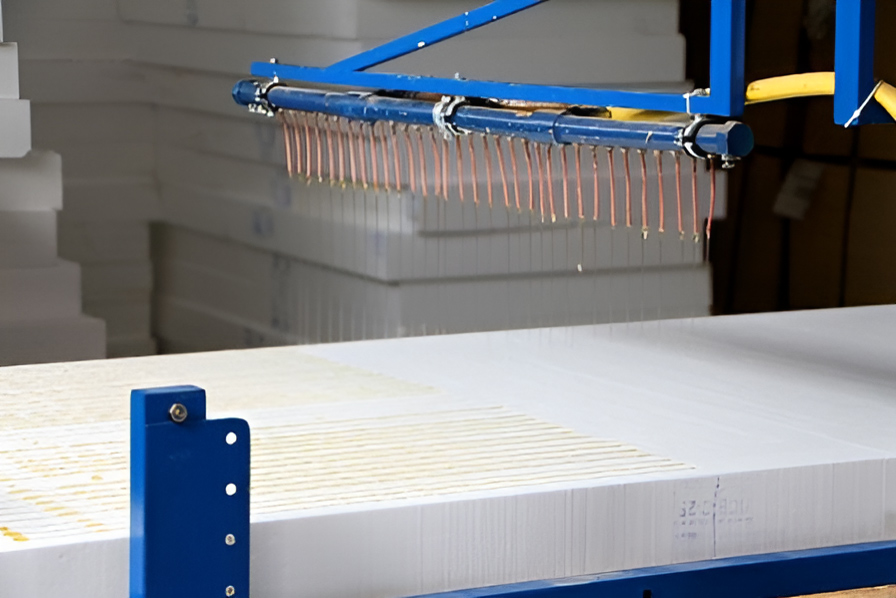

- Adhesive application:

Use appropriate tools like a nozzle or spatula to apply the adhesive evenly across the surface. This ensures the adhesive reaches all areas and prevents air bubbles. The adhesive layer should be thick enough to achieve the desired strength but not excessive to avoid material waste. Proper nozzle use can help control the adhesive amount for a professional finish.

- Pressing the parts together:

After applying the adhesive, align the parts precisely and apply appropriate pressure to bond them together. Use tools like clamps, weights, or even a press to stabilize the parts. The pressure should be sufficient to distribute the adhesive evenly and create a uniform bond. Ensure the pressure is maintained long enough for the adhesive to cure effectively.

- Drying time:

The drying time of polystyrene adhesives depends on factors such as the adhesive type, ambient temperature, and humidity levels. Each adhesive type requires a different curing time. Following the manufacturer’s instructions is crucial to prevent layer separation. Complete drying ensures the bond is strong and durable.

Additional considerations include:

- Temperature Control: Monitor the ambient temperature during adhesive application to ensure proper curing.

- Safety Precautions: When working with chemical adhesives, including polyurethane polystyrene adhesives, use gloves, masks, and adequate ventilation.

Some of

Polyurethane Products

Advantages of Using Polyurethane Plastofoam Adhesive

Using polyurethane polystyrene adhesives offers numerous benefits, including:- Enhanced structural strength:

- Energy efficiency:

- Increased production efficiency:

- Ease of use:

Purchasing polyurethane polystyrene adhesives

To purchase polyurethane polystyrene adhesives, consult specialized manufacturers or suppliers like Imen Polymer Chemie. With over 30 years of expertise in polyurethane materials, Imen Polymer Chemie prioritizes customer satisfaction. The company offers both one-component and two-component polystyrene adhesives along with premium customer services:- Polyurethane technical support: Receive technical consultations and training to achieve maximum product quality.

- Easy ordering: Enjoy fast delivery and even custom production tailored to your project needs.

- Customizable polyurethane materials: Benefit from products manufactured to meet specific customer requirements.