Table of contents

These panels are no longer seen as just an alternative to traditional roofing systems; they are now recognized as advanced building components designed to meet today’s technical, environmental, and economic demands. Roof sandwich panels are popular because they combine several key functions in one product. They provide structural strength, thermal insulation, moisture resistance, and design flexibility through a smart multilayer structure. As energy-efficiency standards continue to rise worldwide, the use of high-performance roofing systems like sandwich panels is growing rapidly. In this article we will give you a clear and practical overview of roof sandwich panels, their main types, and the important role of polyurethane materials in achieving reliable and efficient roofing performance.

What is a roof sandwich panel?

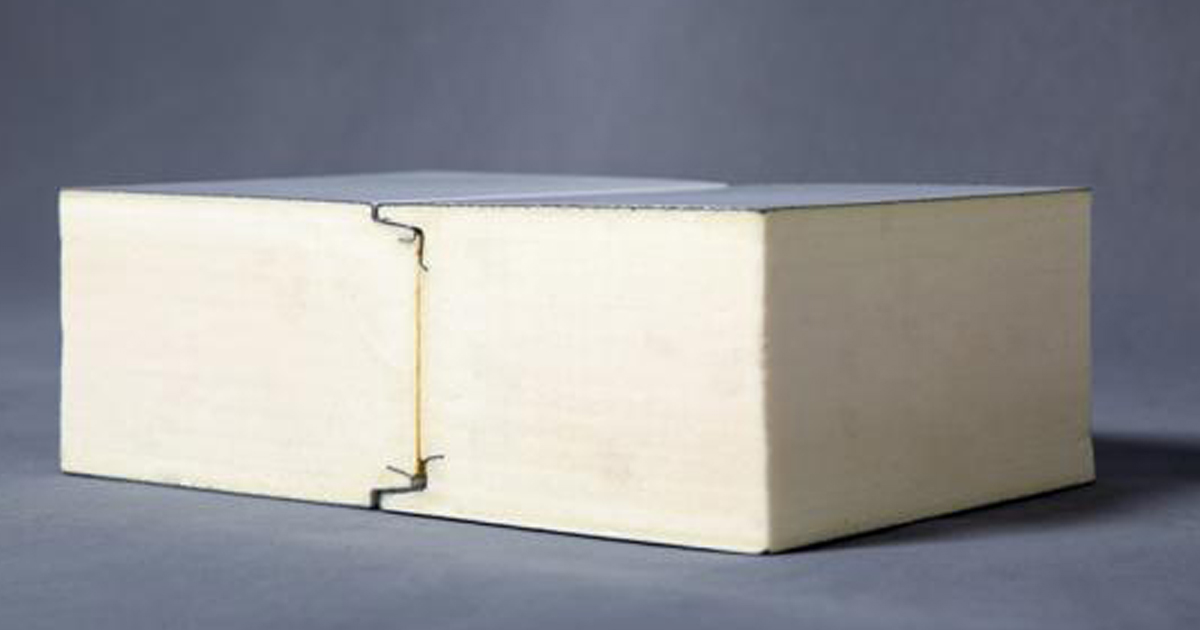

A roof sandwich panel is a prefabricated construction element that has three main layers: two outer facing sheets and an insulating core material positioned between them. The outer layers are typically made of metal sheets such as galvanized steel or aluminum, while the core consists of a high-performance insulation material, most commonly polyurethane or polyisocyanurate. These layers are bonded together under controlled industrial conditions to form a single, rigid panel with consistent quality and predictable performance.

The structure of sandwich panels is based on how different layers work together as one strong unit. The outer sheets provide mechanical strength and resistance to external loads such as wind, snow, and impact, while the core material delivers thermal insulation and contributes to the panel’s overall stiffness. This combined design allows roof sandwich panels to cover long distances with fewer supports, which lowers the overall weight of the roof and makes installation much faster. Unlike traditional roofing systems that are built layer by layer on-site, sandwich panels are factory-made with high accuracy. This results in fewer installation mistakes and a much shorter construction time.

Advantages of roof sandwich panels compared to traditional roofing systems

One of the most important advantages of roof sandwich panels is their exceptional thermal performance. Traditional roofing systems are usually built from several separate layers that are installed one by one. This can create gaps, where heat and air escape. Roof sandwich panels are different because they are made as a single, integrated system with continuous insulation. This helps keep the temperature inside the building stable, reduces energy loss, and lowers heating and cooling costs throughout the year.

Another key benefit of roof sandwich panels is faster and easier construction. They are lightweight but strong, which makes them simple to transport and install. Because the panels are large, wide roof areas can be covered quickly, especially in industrial buildings, warehouses, and commercial spaces. Since the panels are produced in a factory under controlled conditions, quality is consistent, on-site work is reduced, and material waste is minimized. Over time, this results in lower maintenance costs and a longer-lasting roofing system.

Types of roof sandwich panels based on their external design

The outer design of roof sandwich panels affects both how the roof performs and how it looks. Different surface shapes are created to handle specific needs such as strength, water drainage, and visual style. Choosing the right panel design helps the roof perform well under weather conditions while also keeps the building overall appearance.

1.Trapezoidal roof sandwich panel

Trapezoidal roof sandwich panels are one of the most common options for industrial and commercial buildings. Their outer sheet has a trapezoidal shape that increases strength and stiffness. This design helps the panels withstand strong winds and heavy snow loads, making them suitable for large roofs such as factories, warehouses, and logistics centers.

In addition to strength, the trapezoidal shape helps rainwater flow easily toward drainage systems. This lowers the chance of water buildup and roof leakage, especially in areas with frequent rainfall. Trapezoidal panels are also cost-effective, offering a good balance between performance, durability, and price, which is why they are widely used in large-scale projects.

2. Tile-effect roof sandwich panel

Tile-effect roof sandwich panels are made to look like traditional roof tiles while providing the technical advantages of modern sandwich panels. They are often used in residential buildings, villas, and commercial projects where appearance is important. The tile-style surface creates a classic roof look without the heavy weight and complex installation of traditional tiles.

These panels still offer strong insulation and structural reliability while keeping the roof lightweight. This makes them a good choice for buildings with load limitations. Because they are factory-made, tile-effect panels are installed faster and with better alignment than traditional tile roofs, resulting in a cleaner and more durable final appearance.

3. Flat (smooth) roof sandwich panel

Flat or smooth roof sandwich panels have a simple and clean surface with no visible patterns. This design is popular in modern architecture where a minimal and modern look is preferred. Flat panels are commonly used in office buildings, modern commercial spaces, and certain industrial facilities.

Even with their simple design, flat panels provide dependable strength and effective insulation. They are usually installed with suitable fastening systems to ensure proper load distribution. Their smooth surface also makes cleaning and maintenance easier, which is especially useful in buildings that require high hygiene standards or controlled environments.

Types of roof panels based on insulation core material

The insulation core is the most important part of a roof sandwich panel because it has a direct effect on thermal insulation, fire performance, and long-term durability. Several materials are commonly used as the core, including polyurethane, polyisocyanurate, mineral wool, and expanded polystyrene. Each of these materials has specific advantages and limitations depending on the project requirements.

Polyurethane-based cores are widely considered the most efficient option because they offer very low thermal conductivity and high strength while they have low weight. Mineral wool cores are usually chosen for projects that require high fire resistance, but they often need to be thicker to provide insulation levels similar to polyurethane. Expanded polystyrene is generally selected as a more economical solution, although it typically provides lower thermal insulation and less mechanical strength compared to polyurethane systems.

Types of roof panels based on outer sheet material

The choice of outer sheet material influences the durability of roof sandwich panels and also their resistance to corrosion, UV radiation, and environmental exposure. Galvanized steel sheets are commonly used due to their strength and affordability, often enhanced with protective coatings to improve corrosion resistance.

Aluminum sheets provide excellent corrosion resistance and lower weight, making them suitable for coastal or highly humid environments. In some specialized applications, stainless steel or pre-painted metal sheets are used to meet specific aesthetic or hygienic requirements. Selecting the appropriate outer sheet material ensures that the roof panel keeps its performance and appearance over decades of service.

What is the best type of roof sandwich panel?

Choosing the best type of roof sandwich panel depends on several factors, including technical needs, environmental conditions, and cost considerations. Climate, how the building will be used, the amount of load and pressure the roof must handle, and available budget, all play a role in the process of decision making. Because each project is different, there is no single panel type that works best in every situation, and the right decision should be based on performance requirements.

In many cases, roof sandwich panels with polyurethane insulation cores provide the most balanced solution. They offer strong thermal insulation, good mechanical strength, and reliable long-term performance. When these panels have suitable outer sheet materials and the correct panel design, polyurethane roof sandwich panels can meet modern construction requirements while also helping to reduce energy use and support sustainability goals.

Polyurethane Products

Advantages of polyurethane roof sandwich panels

Polyurethane roof sandwich panels are known for their superior thermal insulation properties. The closed-cell structure of rigid polyurethane foam reduces heat transfer, allowing thinner panels to achieve high insulation values. Lower energy consumption is one of the key results of this system, and it also allows more usable space to remain inside the building envelope.

In addition to thermal insulation, polyurethane foam cores provide strong dimensional stability and effective moisture resistance. Their insulating performance remains consistent over time and under different environmental conditions. Because of these properties, panels with polyurethane cores are especially suitable for industrial roofs, cold storage buildings, and structures exposed to very hot or very cold environments.

Purchasing polyurethane materials for roof sandwich panel production from Iran

For roof sandwich panel manufacturers, the quality of polyurethane raw materials has a direct impact on product performance and production consistency. Reliable raw materials help ensure stable insulation properties, uniform panel quality, and smooth manufacturing processes. In recent years, Iran has become an important source of polyurethane materials, offering competitive costs, strong technical knowledge, and increasing export capacity. Choosing the right raw material partner ensures stable production and reliable panel quality.

Imen Polymer Chemie is a specialized producer of polyurethane raw materials that supports roof sandwich panel manufacturers at this level. Our company develops polyurethane systems designed to match specific technical needs and climate conditions, helping manufacturers achieve effective insulation, strong panel structure, and efficient processing. In addition to material supply, our technical guidance and formulation support further strengthen production reliability, making sourcing polyurethane materials from us a simple and reliable choice.

Conclusion

Roof sandwich panels are now a key part of modern construction because they help solve common challenges such as energy efficiency, structural strength, and fast installation. Due to their smart design, advanced materials, and factory-controlled production, these panels provide strong, durable, and reliable roofing solutions for many types of buildings. Knowing the different types of roof sandwich panels, including their surface design, insulation core, and outer sheet materials, helps engineers, manufacturers, and builders choose the right option for both technical needs and visual goals.

Among all available choices, roof sandwich panels with polyurethane insulation cores offer some of the best overall performance. They provide excellent thermal insulation, long service life, and flexibility for different applications. By using high-quality polyurethane raw materials from experienced producers like Imen Polymer Chemie, manufacturers can meet international quality standards and market expectations with confidence. As construction moves toward more efficient and sustainable solutions, roof sandwich panels will continue to play an important role in modern building design.