Table of contents

Your foot is your second heart, so choosing the shoe with the right sole is of great importance. As you might know, shoe soles can be produced with various materials and different properties. Consequently, we will discuss the two key materials used for shoe sole manufacturing; polyurethane and rubber soles. Keep reading to find out more.

Polyurethane vs. rubber soles, which one is best for your needs?

When selecting the right material for shoe soles, both polyurethane (PU) and rubber are popular choices, each with distinct properties. However, polyurethane has increasingly become the preferred material in various industries due to its versatility, durability, and performance. Applications of shoes are various (they can be used for athletic shoes to industrial footwear), therefore understanding the differences between these two materials can help consumers and manufacturers make more informed decisions.

Polyurethane soles typically have superior abrasion resistance, excellent load-bearing capacity, and adaptability to different temperatures. Rubber, while known for its elasticity and impact resistance, tends to wear out faster under intense use and can be heavier. Choosing between the two soles depends on the intended application, and it has to be mentioned that for long-lasting wear and high performance, polyurethane is often a better choice.

Why polyurethane soles offer better grip and support?

One of the visible advantages of polyurethane soles is their exceptional grip on a wide variety of surfaces. Because their density can be adjusted and tread designs can be customized, PU soles are able to provide outstanding traction even in slippery or oily environments. This makes them ideal for work shoes, hiking boots, and sports footwear where secure footing is critical.

Also, polyurethane offers greater structural stability than rubber. Its shock-absorbing capabilities help maintain proper posture and alignment during movement, which result in reducing the risk of injury. Moreover, it can be said that PU soles maintain their shape over time, that ensure consistent support throughout the life-time of the shoe. When rubber soles are pressed, unlike PU soles, they may wear in shorter period of time and lose their form.

After sales service

For price inquiries and purchasing liquid polyurethane for polyurethane foam production, please contact Imen Polymer Chemie Company.

Comparing the weight and comfort of polyurethane vs. rubber soles

Weight is really an important factor that affects in comfort, especially for individuals who spend hours on their feet. Generally, polyurethane is lighter than rubber, which directly result in reduced leg fatigue and easier mobility. It is essential to state that its lightweight nature does not have negative impact on its strength. In other words, PU keeps its durability despite its reduced mass.

Comfort is also increased by the cushioning effect of polyurethane. It distributes pressure more evenly across the sole of the foot, reducing localized strain. Although, rubber might sometimes be softer in some formulations, but it does not provide the same level of engineered responsiveness. As a result, PU soles are often preferred in ergonomic footwear designed for long term usage or physically demanding tasks.

How polyurethane soles reduce foot fatigue for all-day comfort?

Foot fatigue is a common problem for workers, athletes, and anyone who spends long periods walking or standing. Polyurethane’s unique molecular structure allows it to absorb and disperse shock efficiently, which helps to minimize the stress that is gathered on feet, knees, and lower back. This property significantly leads to reduced fatigue during daily activities.

Furthermore, polyurethane soles can be engineered with multi-density zones particularly dual-density designs, show specific pressure points, and offer targeted relief and comfort. Unlike rubber, which provides a uniform feel across the entire sole, polyurethane can be tailored to support natural foot movement, improving comfort over long durations and enhancing the overall user experience.

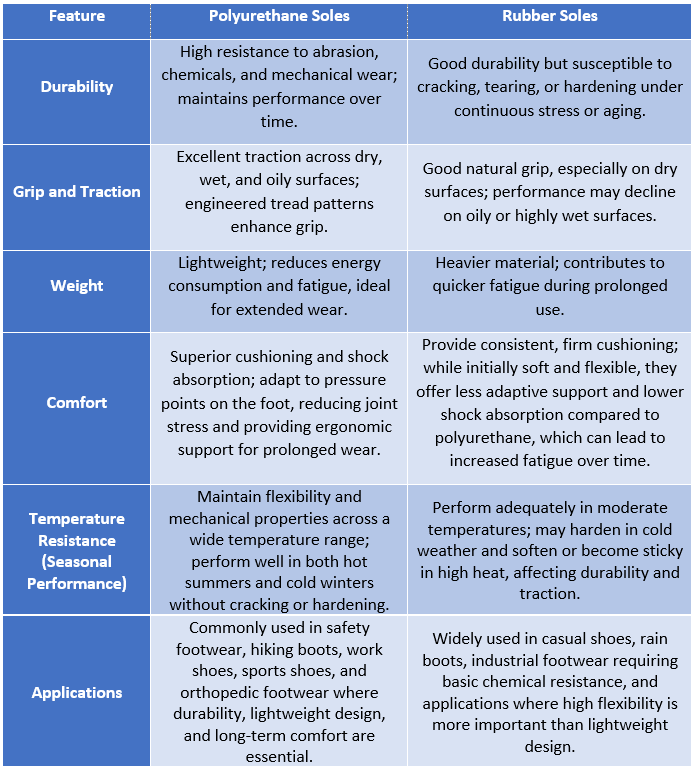

In the following, we compered the two soles in a table:

The environmental impact of polyurethane vs. rubber soles

Now a days, environmental considerations has become increasingly important in material selection. Polyurethane, although synthetic, can be produced with reduced environmental impact, this can be done through moving toward eco-friendly and recyclable formulations. Also, it has to be said that some polyurethane systems are now water-based or made with bio-based polyols, reducing reliance on fossil fuels.

On the other hand, while natural rubber is biodegradable, its production often involves deforestation and intensive labor, leading to significant ecological and ethical concerns. Synthetic rubber, widely used in mass-produced soles, shares many of the environmental downsides of petroleum-based products. By contrast, polyurethane manufacturers are developing more sustainable practices, making PU a promising alternative in eco-conscious footwear design.

Conclusion

Polyurethane shoe soles have shown numerous advantages over rubber soles. That’s why they are becoming more and more popular in footwear industry. In this article we reviewed the main points about PU soles. If you have further questions, leave us a comment or contact us directly.