Table of contents

In this article, we will introduce you to the different types of pipe insulation; by the end, you will find out why polyurethane materials have become so popular in the market. Also, we will guide you in purchasing polyurethane pipe insulation raw materials from Iran.

Different types of pipe insulation

Choosing the right pipe insulation depends on several factors such as temperature resistance, moisture control, chemical compatibility, and of course your budget. The most common types including:

1. Polyethylene pipe insulation

Polyethylene is one of the most widely used materials for insulating residential piping systems, particularly for cold and hot water lines. It is a closed-cell foam that is lightweight, flexible, and easy to install. Polyethylene insulation is moisture-resistant, which helps prevent pipe sweating and corrosion. It’s generally used in environments where temperature extremes are not a major concern.

2. Polyisocyanurate (PIR) pipe insulation

Polyisocyanurate, often abbreviated as PIR, is a rigid foam insulation material with excellent thermal resistance. It is particularly suitable for HVAC systems and chilled water pipes. PIR is chemically similar to polyurethane but has a higher closed-cell content and a greater resistance to fire and moisture. This material offers a high R-value per inch and is frequently used in commercial and industrial settings.

3. Polystyrene pipe insulation

Polystyrene insulation comes in two main forms: expanded (EPS) and extruded (XPS). Both types are rigid, closed-cell foams are water resistance. XPS offers better thermal performance (compared to EPS) and is often used in underground or external pipe insulation where moisture resistance is crucial. Polystyrene is ideal for applications requiring a budget friendly insulation.

After sales service

For price inquiries and purchasing liquid polyurethane for polyurethane foam production, please contact Imen Polymer Chemie Company.

4. Polyurethane pipe insulation

Polyurethane foam is among the most efficient insulation materials available today, making it ideal for demanding industrial applications. With an exceptionally low thermal conductivity, polyurethane provides excellent insulation with minimal thickness. It performs well across a wide temperature range and is resistant to water, chemicals, and mechanical stress.

Polyurethane is especially popular in district heating and cooling networks, oil and gas pipelines, and refrigeration systems. Its closed-cell structure ensures superior moisture resistance, preventing corrosion under insulation (CUI). Moreover, it is compatible with various jacketing materials, such as polyethylene, aluminum, and PVC (in other words it has great adhesion to various substrates).

5. Fiberglass pipe insulation

Fiberglass insulation is composed of fine glass fibers and is typically used for high-temperature applications. It is available in both rigid and flexible forms, often with an external vapor barrier such as foil. Fiberglass offers excellent thermal performance and is commonly used in HVAC systems, steam lines, and industrial piping. However, it is sensitive to moisture and may require additional protective coatings in humid environments. Also, it can deteriorate over time and start to sag.

6. Mineral wool pipe insulation

Mineral wool, also known as rock wool or stone wool, is made from volcanic rock and other natural materials. It is a dense, fire-resistant insulation that provides excellent thermal and acoustic performance. Mineral wool can withstand extremely high temperatures and is non-combustible, making it ideal for fire safety applications. It also offers good water repellency, although not as much as closed-cell foams. It has to be mentioned that this insulation will sag over time so, it can not provide uniform thermal conductivity.

7. Rubber foam insulation

Flexible elastomeric rubber foam is another common type of insulation, particularly for HVAC and refrigeration lines. It is closed-cell, offering good resistance to moisture, UV, and chemicals. Its flexibility makes it suitable for systems with bends and irregular shapes. Rubber foam also offers sound-dampening properties to some extent, making it a multifunctional choice.

8. Cellular glass insulation

Cellular glass is a rigid insulation made from crushed glass and carbon. It is completely inorganic, non-combustible, and resistant to moisture, fire, and most chemicals. Cellular glass is suitable for high-temperature and cryogenic applications and is often used in petrochemical and power generation industries. Cellular glass pipe insulation is so brittle; this makes the installation process hard and costly.

Benefits of polyurethane pipe insulation

Among all pipe insulation materials, polyurethane foams are the material of the choice due to their outstanding properties. These includes the following:

- High thermal efficiency: Lower thermal conductivity reduces energy loss.

- Compact thickness: Less material needed for the same insulation value (it has high R-value).

- Durability: Resistant to mechanical stress, chemicals, and water. It will not sag or lose its strength as time passes.

- Temperature resistance: Performs well in a wide range of temperatures. It also tolerates temperature fluctuations very well.

- Long-term performance: Maintains structural integrity over time.

Applications of polyurethane pipe insulation

Based on above mentioned advantages; polyurethane foam can be used in different industries as pipe insulation; including:

- District heating and cooling networks

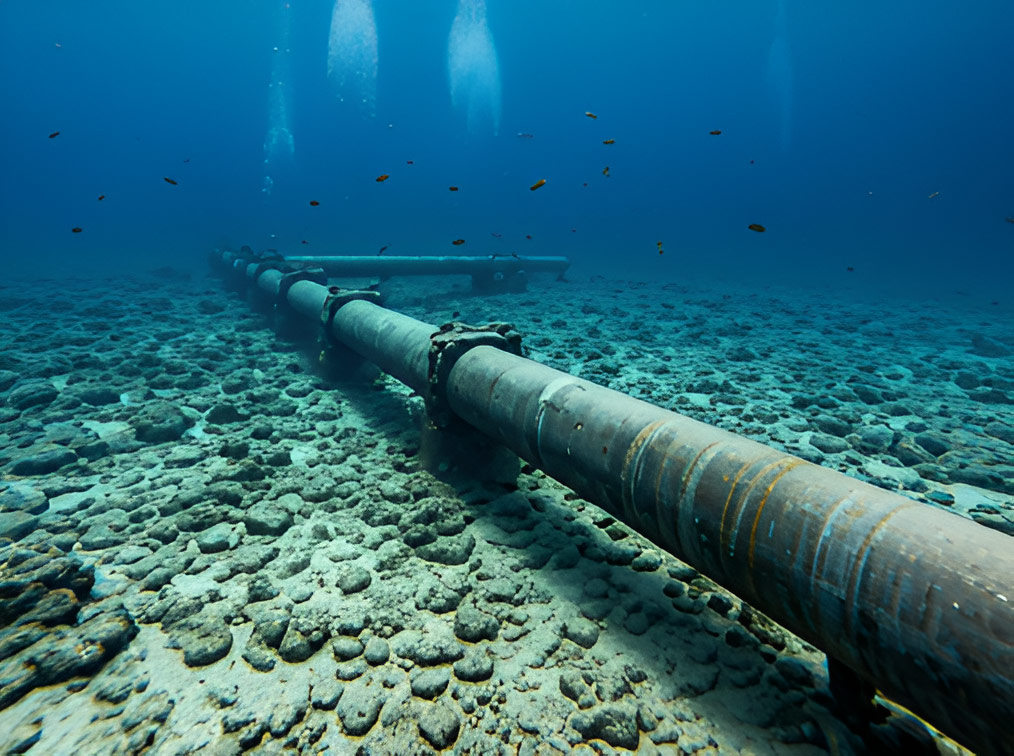

- Oil and gas pipelines

- Cold storage facilities

- Food and beverage industries

- Chemical processing plants

- Marine and offshore structures

Factors to consider when choosing pipe insulation

When selecting insulation, you’d better consider some factors as follows:

- Temperature range: Ensure the material can withstand operating temperatures.

- Moisture exposure: Choose closed-cell options for humid environments.

- Mechanical impact: Rigid foams offer better protection against physical damage.

- Chemical resistance: Consider exposure to corrosive substances.

- Fire safety: Look for fire-retardant properties where needed.

- Method of applying: Spray polyurethane foam need professional operator to apply it, but there is premanufactured insulation that only need to be assembled.

- Above/underground exposure: Some pipe insulations can resist high stress so they can only be used as insulation of above ground pipes.

Purchasing raw materials for polyurethane pipe insulation foam from Iran

Iran is a growing hub for the production of polyurethane raw materials, with Imen Polymer Chemie being one of the leading manufacturers and the (PU) system house. With years of experience and technical expertise, Imen Polymer Chemie provides high-quality polyol and isocyanate systems specifically formulated for pipe insulation applications. These materials are designed to meet international performance standards and can be customized based on climatic and mechanical requirements.

Exporting from Iran offers several advantages:

- Cost-effective production due to local resource availability

- Technical support for application development and process optimization

- Customized formulations for specific project needs

- Reliable supply chain for international customers

Buyers from Europe, Asia, and the Middle East can benefit from competitive pricing and robust quality assurance processes when sourcing polyurethane raw materials from Iran.

Why choose Imen Polymer Chemie?

Imen Polymer Chemie stands out for its commitment to innovation, customer satisfaction, and technical excellence. Our company offers:

- Tailor-made polyurethane systems for different pipe insulation requirements

- On-site and remote technical consultation

- R&D support to improve insulation efficiency

- Compliance with global safety and performance standards

Conclusion

Choosing the right pipe insulation material is necessary for ensuring energy efficiency, system durability, and cost savings. Among all the available options, polyurethane foam offers the best balance of thermal performance, durability, and moisture resistance, making it the preferred choice for industrial applications. If you’re looking for a reliable source of polyurethane raw materials, Imen Polymer Chemie from Iran is ready to support your project with advanced formulations and expert guidance.

Just contact us today to learn more about our polyurethane solutions and how we can help you optimize your insulation projects. Whether you’re planning a new build or retrofitting an existing system, our team is here to deliver materials and support tailored to your needs.