Construction industry

Polyurethanes, due to their low thermal conductivity, are primarily used as thermal insulation in buildings. Nowadays, this polymer has become a key component in modern constructions, offering suitable durability and applications ranging from sealing to enhancing the strength of structures. In other words, closed-cell polyurethane foams can be used to reduce energy loss and, consequently, lower utility bills. On the other hand, open-cell foams have the ability to absorb sound waves, providing greater peace and quiet for residents. Additionally, polyurethane flooring and coatings adhere well to various surfaces, are easy and quick to clean, and have an attractive appearance, contributing to their growing popularity.

Product applications

The types of polyurethane foams offered by Imen Polymer Chemie Company for use in the construction industry include thermal insulation spray foam, sound insulation spray foam, pipe insulation, sandwich panels, flooring, and coatings. Some applications of this product in the construction industry are listed below:

- Insulating warehouses

- Insulating mushroom cultivation halls

- Insulating poultry farms

- Sports, laboratory, and parking flooring

- Sound insulation for conference halls and theaters

- Thermal insulation for residential apartments

- Insulation for villas

- Insulation for commercial shopping centers

After-sales services

We never leave you

on your own afterwards either

Imen Polymer Chemie

Some of our latest

Air conditioner pipe insulation: Types, benefits, and best materials

Spray polyurethane foam roofing

Roof sandwich panels and their different types

Role of polyurethane in the construction industry

The construction industry continuously seeks innovative materials that enhance durability, energy efficiency, and sustainability. Among these materials, polyurethane stands out due to its versatility, excellent insulation properties, and resistance to environmental factors. Polyurethane is widely used in construction applications such as insulation, coatings, adhesives, and sealants. Its unique chemical structure allows it to provide superior performance, making it a preferred choice for builders and engineers worldwide.

This article explores the applications, benefits, and future trends of polyurethane in the construction sector, highlighting why it has become indispensable specially in modern building projects.

How polyurethane foam is transforming the construction industry

Polyurethane is a polymer composed of organic units joined by urethane links (-NHCOO-). It can exist in various forms, including rigid and flexible foams, elastomers, and coatings, making it highly adaptable to different construction needs. The material is formed through the reaction of polyols with diisocyanates, resulting in a durable and resilient product.

Polyurethane’s unmatched properties, such as thermal insulation, moisture resistance, and mechanical strength, make it an essential component in construction materials. Whether used as an insulating foam, protective coating, or structural adhesive, polyurethane enhances the performance and longevity of buildings.

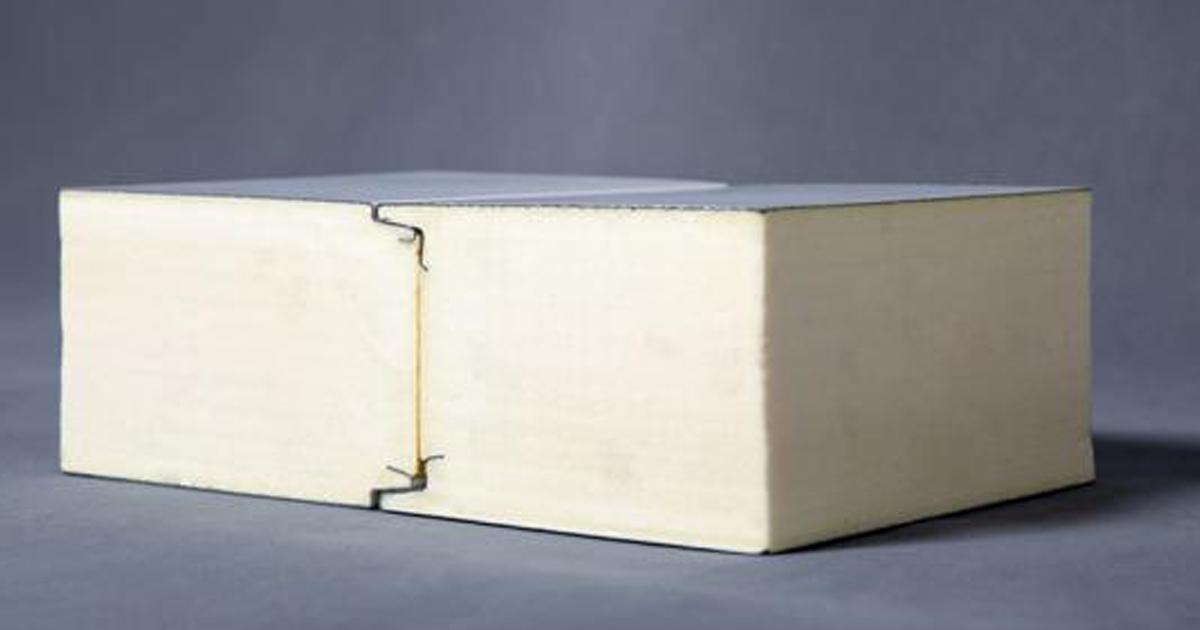

Closed-cell polyurethane foam

Closed-cell rigid polyurethane foam stands out as a high-quality insulation material, offering exceptional thermal performance for both construction and appliance applications. Its popularity continues to grow, driven by increasingly rigorous energy efficiency regulations and the global push for more sustainable building solutions. This demand has driven new ideas to make these foams insulate better.

The superior thermal insulation of closed-cell PU foam is rooted in its structure. The foam’s morphology, the intrinsic properties of the polyurethane material, and the type of gases trapped within its cells all play a crucial role in minimizing heat transfer. Understanding how these elements work together reveals why PU foam is such an effective insulator.

By optimizing the cell size, gas composition, and polymer matrix, manufacturers can significantly reduce these heat transfer mechanisms, creating foams that meet and exceed modern energy standards.

As the industry grows, the goal is to create better and greener formulas so that closed-cell PU foam continues to be a leading choice for insulation.

Applications of polyurethane in the construction industry

Polyurethane materials can be used in different industries specially building and construction industry. Their applications include:

1. Insulation materials

Polyurethane foam is one of the most effective insulation materials available. It is commonly used in walls, roofs, floors, and ceilings to avoid energy loss. The foam has the lowest thermal conductivity compared to traditional insulation materials like rock wool, polystyrene foam and so on.

Spray polyurethane foam (SPF)

Used for thermal and sound insulation, SPF expands to fill gaps and voids, preventing air leakage and enhancing the building’s energy efficiency. It is applied quickly and adheres perfectly to various substrates.

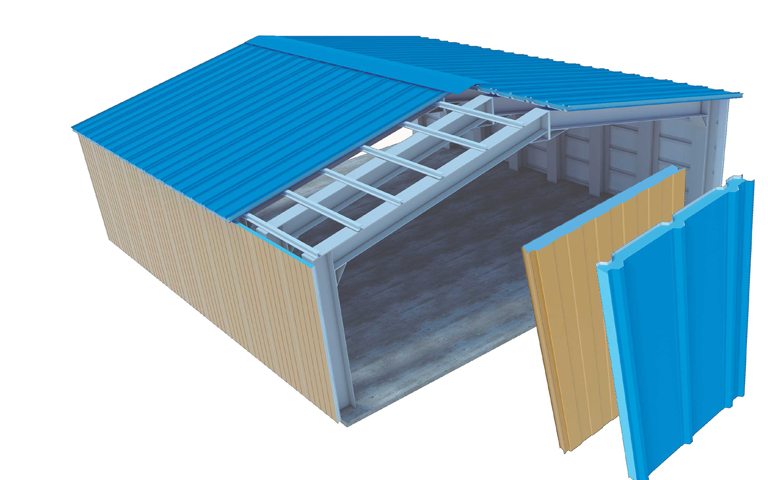

Polyurethane sandwich panels

These polyurethane sandwich panels are widely used in commercial and residential buildings for their high R-value, ensuring superior thermal insulation.

2. Polyurethane coatings

Polyurethane coatings provide a protective layer to various surfaces, increasing durability and resistance to environmental factors such as UV radiation, moisture, and chemicals.

Coatings:

Applied to enhance the long life of substrate by protecting them from harsh environment conditions.

Floor coatings:

Used in industrial and commercial settings to create durable, slip-resistant, and aesthetically pleasing floors.

3. Sealants and adhesives

Polyurethane-based adhesives and sealants are crucial in the construction industry for their excellent bonding strength, durability, and flexibility. These materials are widely used in various applications to enhance structural integrity and longevity.

Expansion joint sealants

Used in bridges, roads, and buildings to thermal expansion, contraction, and structural movement in infrastructure such as bridges, roads, and buildings. They provide a waterproof barrier, preventing water infiltration and protecting against damage caused by moisture.

Structural adhesives

Ensure strong bonding between different construction materials, including concrete, wood, and metal. They offer excellent resistance to environmental stressors such as temperature fluctuations, UV exposure, and mechanical loads, making them ideal for both indoor and outdoor applications.

4. Waterproofing and water stopping solutions

Waterproofing is a critical aspect of construction, and polyurethane materials are widely used to prevent water infiltration.

Liquid-applied polyurethane materials

Used in basements, tunnels, and bathrooms to create a seamless, watertight barrier.

Polyurethane grouts

Injected into cracks and joints to prevent water seepage.

Advantages of using polyurethane in construction

Using Polyurethane in Construction has numerous advantageous including the following:

1. Superior thermal insulation

Polyurethane foam has one of the highest R-values per inch compared to other insulation materials. This means it provides excellent thermal resistance, reducing heating and cooling costs significantly.

2. Moisture and water resistance

Unlike traditional insulation materials such as fiberglass, polyurethane does not absorb water. This prevents mold growth and structural damage caused by moisture infiltration.

3. Lightweight yet strong

Polyurethane offers high mechanical strength while remaining lightweight. This makes it easier to handle and install without compromising durability.

4. Versatility in applications

Due to its various formulations, polyurethane can be adapted to multiple construction applications, including insulation, waterproofing, adhesives, and coatings.

5. Long-term durability

Buildings that incorporate polyurethane components tend to have a longer lifespan due to the material’s resistance to wear, chemicals, and environmental stressors.

6. Sustainability and energy efficiency

With increasing demand for energy-efficient buildings, polyurethane plays a vital role in reducing energy consumption. Its insulating properties contribute to lower carbon emissions, making it an environmentally friendly choice.

Future trends in polyurethane construction applications

With advancements in material science, polyurethane continues to evolve, offering even more benefits to the construction sector.

Smart polyurethane materials:

Development of self-healing polyurethane coatings and foams that can repair minor damages automatically.

Eco-friendly polyurethane:

Research is being conducted on bio-based polyurethanes to reduce dependency on fossil fuels.

Integration with 3D printing:

Polyurethane-based 3D printing materials are being explored to create customized building components with enhanced performance.

How to buy polyurethane material for construction from Iran?

Ordering polyurethane raw materials from Iran, particularly from Imen Polymer Chemie, is an easy and efficient experience. Thanks to a strong production infrastructure and a commitment to meeting global quality standards, we are fully equipped to serve international markets.

We supply a wide range of polyurethane raw materials for various applications, ensuring high performance and reliability. Whether for construction, insulation, adhesives, coatings, or other industries, our products are designed to deliver the best results. As an experienced exporter, we handle everything from logistics and documentation to compliance with international trade regulations, making the purchasing process easy for our customers.

For buyers worldwide, we offer flexible shipping options, competitive pricing, and expert technical support to help you find the right materials for your needs. Every order is carefully processed to meet the highest industry standards. Whether you need insulation foams, sealants, adhesives, or coatings, Imen Polymer Chemie is a reliable partner, delivering high-quality polyurethane solutions to markets across the Middle East, and beyond.

Why choose Imen Polymer Chemie for polyurethane building materials solutions?

As a leading producer of polyurethane raw materials, Imen Polymer Chemie offers high-quality solutions tailored to the construction industry’s needs. With years of experience and a commitment to innovation, we provide a wide range of polyurethane products, including insulation foams, coatings, adhesives, and sealants.

Custom formulations:

Our R&D team develops specialized polyurethane formulations to meet specific project requirements.

Technical support:

We offer comprehensive guidance on the proper application and handling of polyurethane products.

Sustainable solutions:

Our products contribute to energy-efficient and environmentally friendly construction practices.

Reliability and performance:

Our polyurethane materials are tested to ensure superior durability and performance in demanding construction environments.

Get in touch with us today!

If you’re looking for high-performance polyurethane materials for your construction projects, Imen Polymer Chemie is here to help. Contact us today to learn more about our products and how we can support your building needs.

Conclusion

It can be said that polyurethane has really changed the construction industry by providing innovative solutions for insulation, waterproofing, adhesives, and coatings. Its unmatched performance, durability, and sustainability make it a key material in modern construction projects. As the industry moves towards energy-efficient and eco-friendly building solutions, polyurethane will continue to play a vital role in shaping the future of construction. By choosing high-quality polyurethane materials from trusted suppliers like Imen Polymer Chemie, builders and engineers can ensure long-lasting and efficient structures.