Furniture industry

Polyurethane is a popular material in the furniture manufacturing industry due to its unique properties. Its main advantages include high resistance to abrasion, scratches, and impacts. Additionally, polyurethane can have a sleek and attractive appearance, making it widely used in the design of office and home furniture.

Cold cure foam is a type of polyurethane that, in addition to having good physical properties, offers suitable softness and flexibility, making it widely used as foam for seating cushions. Wood imitation foam creates an appearance similar to wood and is used in the design of wooden furniture (it can be used as natural wood substitution). On the other hand, when better durability is needed, integral foams are a better replacement for cold cure foams.

Overall, the use of polyurethane in furniture manufacturing provides high durability and longevity to the furniture, allowing manufacturers to achieve a new level of quality. The types of polyurethane foams offered by Imen Polymer Chemie Company for use in the furniture manufacturing industry include cold cure foam, imitation wood foam, and integral foam.

Product applications

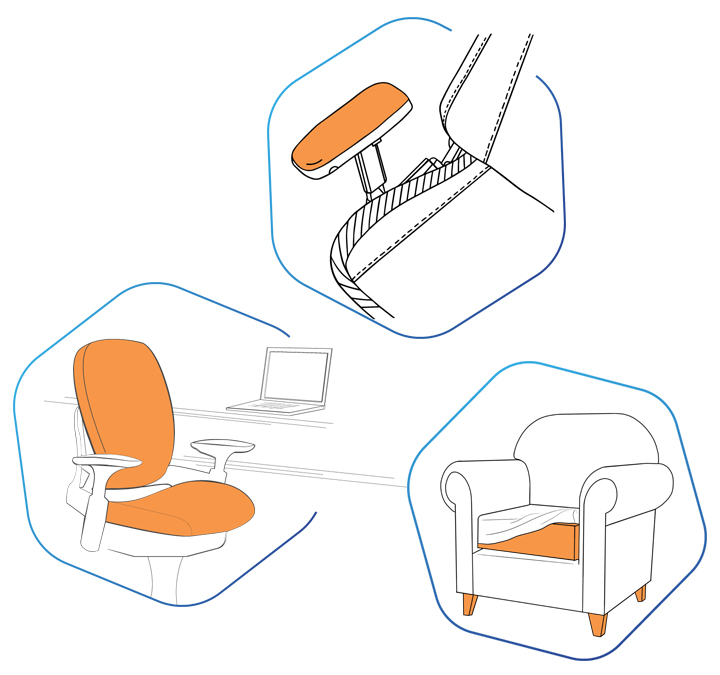

Therefore, polyurethanes are highly versatile and can be used in various parts of furniture, including the following:

- Furniture frames

- Sofa cushions

- Chair, table, and sofa legs

- Sofa backs

- Office chair foam

- Office chair armrests

After-sales services

We never leave you

on your own afterwards either

Imen Polymer Chemie

Some of our latest

Imen Polymer Chemie, leading polyurethane raw material manufacturer, participated in the 25th Tehran home appliances exhibition

Top polyurethane material supplier in Qom – Imen Polymer Chemie

Discover innovation with Imen Polymer Chemie at the 2025 Tehran International Home Appliance Exhibition

Furniture foams

As you know, foams are one of the main components in furniture manufacturing. These materials must have various properties such as softness, flexibility, strength, and high durability. They are categorized based on different materials and characteristics. Soft and comfortable foams are the best option for sofas and cushion production.

Among various materials, polyurethane foams have gained significant attention due to their superior characteristics. In other words, it can be stated that the foams have made a big difference in the furniture industry. From flexible cushioning foams to rigid structural components and decorative moldings, polyurethane has become an essential building block in this industry.

In this article, we will talk about the benefits of using polyurethane in furniture, its applications, and, overall, the important role of the material in the industry. In the end, we will guide you to have a great purchase if you are sourcing high-quality raw materials for furniture production.

Polyurethane in the furniture industry

Polyurethane has become a needed material especially in modern furniture manufacturing. It is playing an important role in improving both functionality and aesthetics.

Whether it is used in soft seating, cushioning, or structural components (such as furniture frame and chair/table leg), polyurethane shows better efficiency compared to traditional materials. Its flexibility and performance characteristics make it an ideal choice for high-quality furniture, office seating, bedding products, and more.

As a manufacturer or exporter in the polyurethane industry, knowing how they are used in furniture can help you find new customers and grow your business.

Benefits of using polyurethane in furniture

The use of polyurethane in the furniture industry has many advantages; the main ones are mentioned below:

Excellent durability

Polyurethane foam is highly resistant to wear and tear; this results in increased service life compared to traditional sponge foams. It keeps its shape and resilience even under continuous pressure, making it suitable for furniture that are used frequently.

Enhanced design flexibility

Polyurethane systems are highly versatile and their properties such as density, hardness, and elasticity can be customized. This allows designers to produce everything from very soft cushions to firm structural parts, all tailored to specific applications and user needs.

Comfort and ergonomics

Polyurethane provides excellent pressure distribution and body support. Its ability to conform to body contours makes it ideal for seating and bedding applications where user health is a priority.

Lightweight and cost-effective

Compared to many other materials with similar mechanical properties, polyurethane offers an excellent strength-to-weight ratio (lower weight but similar mechanical strength). This helps to reduce production and transportation costs due to simplifying handling and assembly processes.

Thermal and acoustic properties

Polyurethane helps make furniture more useful by reducing heat transfer and blocking noise. This can make homes, offices, or other spaces feel quieter and more comfortable to spend time in.

Applications of polyurethane in furniture

Polyurethane is widely used in furniture manufacturing because it can be made in many different forms, each with its own unique purpose; including:

Both cold cure foam and hot-cure foam are used in molded furniture seats and backs. Cold-cure foam is highly durable, resistant to sagging, and keeps its shape for a long time, even with daily use. In another words, cold-cure foam is produced at lower mold temperatures and that production condition gives it excellent elasticity and long-term support. This makes it ideal for high quality sofas and ergonomic chairs.

Hot cure foam, on the other hand, is cured at higher temperatures and often used when faster production cycles are needed. However, it is usually less durable than cold cure. Therefore, it is frequently used in lower-cost or temporary furniture where long-term performance is not the top priority.

Memory foam is popular for cushions and in the layers of mattresses that need to mold to the user’s body and relieve pressure points. It smoothly contours to the body’s shape, provide a soft support, and help reduce pressure on joints. It creates a very comfortable feeling. It is also used in medical pillows.

Latex foam is another flexible polyurethane foam that unlike memory foam is more bouncy and breathable option, and is often chosen for its natural feel and better durability.

Integral skin foam is a special type of polyurethane used in parts like armrests, and headrests. It has a soft core with a tougher outer layer (has a tough skin), which means it looks smooth and finished without needing extra fabric or covers.

For decorative furniture parts such as trim, legs, or frames, wood imitation foam is a great alternative to real (natural) wood. It can be shaped and painted to look like wood but is lighter and easier to handle. Also, it is more durable than natural wood and has great resistant to water. That’s why it’s become a smart option in furniture designs.

What’s the difference between polyurethane foam and regular sponge foam?

Generally, when we talk about “sponge foam” we mean a sponge made of flexible polyurethane foam so it has an open-cell structure. This cell structure lets the air to penetrate into the sponge, and pass through easily. In other words, this gives the material its soft, and bouncy feel.

It is light weight yet durable, and shows a good resistance to daily use damage. As a result, it can be used in mattresses, furniture cushions, car seats, and so on.

On the other hand, polyurethane foam is a broader term. It includes many different types of foam with varying levels of hardness and density, from very soft and flexible foams (like sponge foam) to rigid, high-density foams used in construction and appliances. For example, rigid polyurethane foam is commonly used for thermal insulation in buildings and refrigerators, while semi-rigid foams may be used in automotive dashboards or structural parts.

While both materials are made from polyurethane, sponge foam specifically refers to soft, open-cell foams used for comfort and cushioning. Polyurethane foam is a general term that covers all types of PU foams depending on the application.

Choosing the right furniture foam

So far, it’s clear that the best foam for furniture is polyurethane, and the foam come into different types. Each of them offers unique properties that impact its use. So, selecting the right foam for your project is necessary for comfort, durability, and appearance. You’d better consider the following factors:

Intended use

The purpose of the furniture plays a key role. For example, seating in public spaces or offices needs durable, supportive foam, while home loungers may benefit more from softer, comfortable options like memory foam or latex foam.

Comfort level

Softness or firmness should match the purpose; for example, lounging furniture may need softer foam, while dining chairs may need firmer support.

Density and firmness

Higher-density foams usually last longer and provide better support. Firmness also affects how the furniture feels when using it.

Budget

Foam types like memory foam or high-resilience foam may cost more, so your budget will influence which material is most practical. Cheaper foams may not last long, so it’s crucial to balance cost with quality.

Moreover, for furniture manufacturers, the quality of polyurethane foam depends on the quality of its raw materials primarily polyols, isocyanates, and additives. Choosing a reliable supplier with deep technical expertise makes you sure that the final foam product has long durability and passes safety requirements.

Buying polyurethane materials for furniture manufacturing

For international buyers and distributors who are sourcing high-quality polyurethane systems for furniture manufacturing, Imen Polymer Chemie offers proven formulations, logistical expertise, and reliable export support.

Whether you’re launching a new furniture product line or looking to improve the performance of existing models, buying the right polyurethane materials is necessary. We have:

- Tailored polyurethane formulations for specific furniture applications

- Expert consultation on foam system selection and processing

- On-time delivery and export documentation support

- Compatibility with high-pressure and low-pressure foam machines

To place your order or consult with our technical team, contact us at +989389692489.

Conclusion

In today’s competitive furniture market, manufacturers need top innovative materials that are high-quality, durable, and cost-effective. Polyurethane materials, due to their unique properties, can fit these needs perfectly. By choosing the right supplier, you can make the most of this flexible and reliable polymeric material.

We at the Imen Polymer Chemie Co. provide top-quality polyurethane raw materials, offer expert technical support, and deliver the best solutions. So, whether you make sofas, ergonomic chairs, or decorative parts for furniture, our products will help improve your quality and boost your business.