Polyurethanes have excellent bonding properties with other materials. This property is unfavorable in the molding of foam bodies.....

In order to quickly and smoothly remove the product from the mold, a mold release agent must be used. Mold release agent forms a barrier between the mold and the surface of the molded part. The action of the release agent is so important that it is directly responsible for the appearance and surface properties of the part once it is unmolded. Furthermore, a suitable release agent can dramatically decrease cycle time and improve molding process efficiency.

By applying polyurethane mold release agent to the surface of the mold, a thermally and chemically stable film can be formed on the surface of the polyurethane product, which facilitates the smooth detachment of the product from the mold. In order to make the product release well, there must be a dense and smooth film on the surface of the mold. It is required that the film does not react with the raw material but also has a certain adhesion to the mold, and at the same time has a certain flexibility.

Kinds of release agents

1. Internal agents:Internal mold release agents are added to polyurethane resin systems and help minimizing or even completely eliminating the need for additional external release agents, at the same time, they do not impair the chemical or physical characteristics of the resin. In other words, they act like a chemical additive which migrates to the surface and lubricates the mold.

Fatty acid derivatives, esters, metal soaps, organic salts and siloxanes/silicones have been tried as polyurethane internal mold release agents. These release agent candidates have been incompatible with the polyurethane matrix resin, separating from the resin and requiring mixing before and during use.

2. External agents:These agents are divided into two main categories: Sacrificial and semi-permanent release agents

- Sacrificial release agents (Wax)

Historically, the most common types of release agents have been naturally occurring waxes and greases. Even today, wax remains the most common form of release agent and one that everyone is familiar with. They are sold in either paste or liquid form, they are relatively safe and easy to use. In addition, they typically only last for one or two releases before they have to be re-applied. They include polyvinyl alcohol (PVA), silicone oils, and more. Silicone release agents have the characteristics of high and low-temperature resistance, low surface tension, and no corrosion to metals.

The main point to know about sacrificial coatings is that while they get applied directly to the mold itself, they do not bond to its surface. As the newly molded part is removed from the mold, these release coatings transfer from the mold to the surface of the part. At this stage in the process, the release agent has been “sacrificed” and must be reapplied to the mold before the next molding cycle can begin.

Sacrificial release agents are particularly useful in molding operations in the composites industry. Wax release agents especially can also improve an imperfect mold’s surface by filling in small pits or flaws, so those imperfections do not transfer to the molded part.

However,

consider the following disadvantages of sacrificial release agents can transfer to a finished part, potentially causing post-painting or gluing issues.

- Semi-permanent release agents

Unlike sacrificial release agents, semi-permanent mold releases bond to the mold surface itself instead of the part. The main advantage of this property is that many molding cycles can take place before the release agent must be reapplied. This greatly reduces cost and cycle times when compared to traditional sacrificial release agents. It also has the major added benefit of providing minimal transfer of the coating to the molded component. It forms a hard or rubbery film (i.e. non-greasy), while maintaining the other requirements of a release agent.

They are typically reactive, cross-linkable resins formulated or dissolved in various inert solvents. They are applied directly to the mold surface and, by a process of solvent evaporation and solute cure, form a complete, uniform thin film over the entire mold surface. Although the production of a crosslinked film tends to slightly increase the force required for release (compared to a wax or silicone), it also increases the durability of the film and thus enables many releases to be obtained from one application.

As mentioned above, the increased durability of the film also results in a significant decrease in the amount of transfer from the coated mold to the released polymer, often to such an extent that secondary processing, e.g. painting or bonding, can be performed without a separate surface preparation stage.

Depending on the reactivity of the semi-permanent resin (and there are several types), a chemical reaction occurs with the mold surface. This ensures the release agent remains on the surface of the mold and is not removed with the part when release occurs. The crosslinking of the resin then produces an inert coating of low surface energy capable of releasing most polymers.

The formed film in the mold (compared to the one with sacrificial release agents), is reactive and bond to the mold surface it tends to give a much dryer and harder film with relatively low slip and are therefore not suitable for all applications. It also tends to be less user-friendly than waxes, and requires a cure time after application (although waxes do need to be left to harden before polishing).

Another category for release agents

Polyurethane mold release agents can also be categorized into solvent- or water-based according to the formulation. This has an obvious consequence of solvent-based systems having to be stored in sealed containers and of water-based systems being used in hot molding processes (>60°C).

Organic solvents result in significant VOC emissions; this has led to significant impetus worldwide to reduce/eliminate organic solvents from mold release. The obvious approach of replacing organic solvent with water as the carrier for mold release composition is not without its challenges. Water, with its extensive hydrogen bonding, is a difficult solvent to evaporate. Its low equivalent weight and small molecular size also make it highly reactive with isocyanate. Residual water left in the mold prior to pouring typically results in extensive surface defects of the part. Water, with its high surface tension, is a poor film forming solvent, resulting in poor integrity of the release film. Additionally, emulsifiers required to stabilize the water/wax emulsion.

Advantages of mold release agents

- Superior part release

- Cleaner molds and shorter cycle time

- Excellent surface cosmetics

- Various gloss levels

Choosing a suitable mold release agent

Mold release agents play a vital role in the molded polyurethane foam sector, but their choice involves balancing a number of factors; in other words, there are many factors to consider when deciding on the right release system for a molded polyurethane part, including:

- Environmental impact (tin free release agent)

- Cost

- Safety (lowest VOC emission)

- Efficiency in use

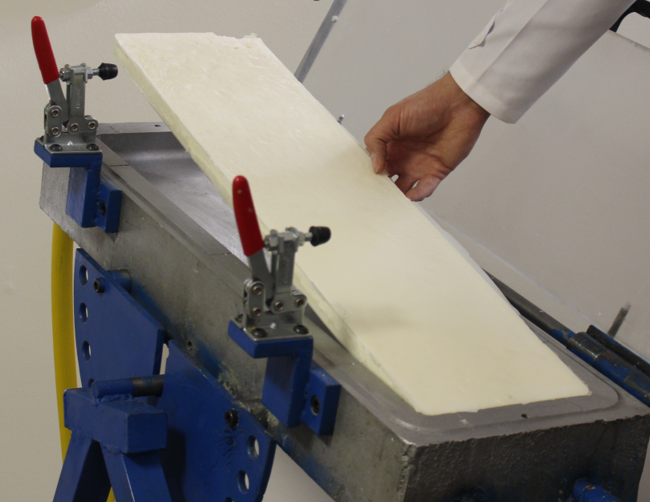

The procedure

1. Applying a thin layer of the release agent to the mold by brush or by the spray2. Time should be spent until the layer dries/cures completely

3. Pouring/injecting the foaming mixture in the mold

Generally, an ideal release agent should:

- Be non-toxic and safe to use (ideally a water-based system)

- Be quick and easy to apply to any mold configuration (i.e., a one-component system with a low viscosity)

- Form a complete and uniform film on the mold surface

- Dry or solidify quickly to minimize production down time

- Be insoluble in the polymer being molded and withstand polymer processing conditions (e.g., temperature, pressure, shear and other abrasive forces), i.e., remain at the polymer/mold interface

- Be chemically inert and possess a surface energy lower than the resin or polymer being molded

- Have a low coefficient of friction to facilitate easy release from deep or complex molds

- Keep the mold clean for as long as possible

- Be low cost, i.e. give the lowest cost per part

In conclusion, it has to be mentioned that there is no universal release agent and this must be adapted to a large number of variables such as

- Temperature

- Material

- Geometry of the mold

- Cycle time or the surface finish of the pieces

The product is available in Imen Polymer Chemie Co. for different kinds of polyurethane foams. For more information, please contact our experts.