Decorative industry

Polyurethane plays a crucial role in the decorative industry as a versatile material. The use of polyurethane wood imitation foam helps to avoid tree cutting and prevents deforestation for making decorative parts.

Compared to natural wood, polyurethane wood imitation foam exhibits higher resistance to decay and mold growth. Additionally, it offers the flexibility to adjust density within a wide range, from 100 to 1000 kilograms per cubic meter. These materials can be easily molded, taking the shape of the mold effectively. Coloring, and drilling are also possible with the obtained samples. Overall, polyurethane wood imitation foam demonstrates greater resistance and strength compared to natural wood.

Product applications

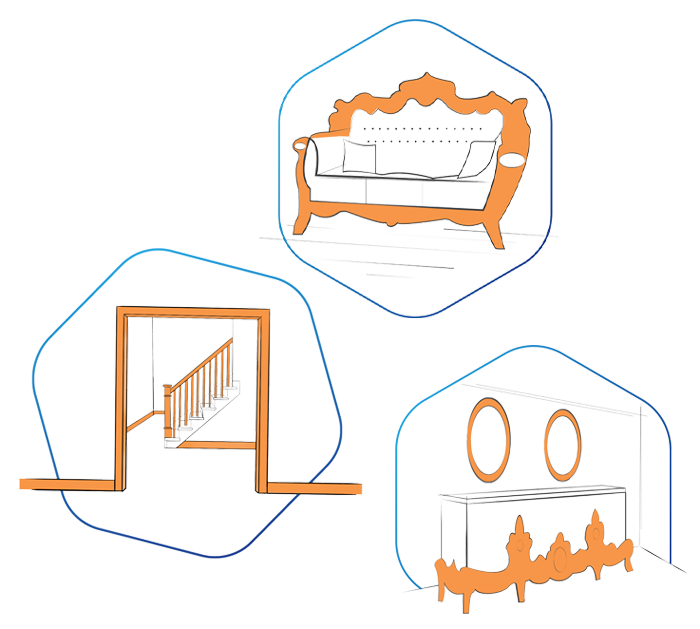

Polyurethane imitation wood foam, offered by Imen Polymer Chemie Company in various densities, is considerably lightweight. It serves as an alternative to natural wood in various applications, including:

- Sofa frames

- Crown molding

- Picture frames

- Mirror frames

- Prefabricated cornices

- Wall cornices

- Sculpture making

- Pedestals

- Rear car parcel shelf

- Car sunroof

- Wooden buffets

- Door cabinet

After-sales services

We never leave you

on your own afterwards either

A revolution in decoration and architecture

Polyurethanes are widely used in industries because of multiple properties and production capability. An example of these industries is the decorative applications where polyurethane stands as one of the best solutions due to its special features. Polyurethane from producing decorative foams to the use in both interior and exterior architecture has found an important place in decoration and architecture industry. This is what we are going to explore further in this content.

Polyurethane in architecture

Polyurethanes have very much extended their domain of application not only in indoor decoration but also in building architecture. Advantages of polyurethane, such as that it is lightweight and insulating has helped with growth in use for construction applications, where weight or weather resistance are issues. Uses of polyurethane in architecture including the following:

Building facades

These are made of polyurethane foams, which have currently been used as light and strong coverings on building facades. The foam can easily take the forms of stone, brick, or wood, among others, reaching really beautiful and unique shapes.

Thermal and acoustic insulation

Polyurethane is one of the main materials used in thermal and acoustic insulation for buildings, due to its excellent insulating properties. It can be applied on walls, ceilings, and floors, thus helping with energy saving.

Green and modern roofs

One of the new usages of polyurethane in architecture is creating green roofs. These roofs, optimized with polyurethane foams, do not only enhance beauty but also help in reducing internal heat and improving air quality.

Exterior decorations

In modern architecture, polyurethane foam is used to make decorative exterior elements resistant to environmental conditions and requiring extremely low maintenance, including but not limited to columns, window frames, and doors.

What is decorative foam?

Decorative foam is a lightweight polyurethane material known for its durability and versatility, making it ideal for both interior and exterior decorations. Often called polyurethane wood imitation foam or wood-like foam, it can be easily shaped into a variety of intricate designs. This flexibility allows designers to craft unique pieces that can be installed in various settings. Essentially, decorative foams can replicate the appearance of more expensive materials such as wood, stone, or metal, while being significantly lighter and simpler to work with. Moreover, using polyurethane foam instead of traditional wood can contribute to reducing deforestation and conserving natural resources.

Applications of decorative foam

Polyurethane decorative foam has brought about a remarkable evolution in various industries, especially in interior design. This versatile product can be utilized to create a range of components, including:

Ceiling and wall decorations

Decorative foams are a favored option for enhancing ceilings and walls. These lightweight, prefabricated polyurethane pieces are easy to install in various settings, enabling the creation of diverse designs such as reliefs, frames, and decorative lines. They are commonly used in the production of prefabricated moldings.

3D panels

Decorative foams are also employed to craft 3D panels that serve as wall coverings. These panels can be shaped in different styles, giving interiors a distinctive appearance. Polyurethane decorative stone panels are a smart choice for achieving beautiful, natural effects in both indoor and outdoor environments.

Decorative columns and capitals

Another important application of decorative foams is in the creation of lightweight columns and capitals for interior decor. These features are especially popular in classical and neo-classical architecture, bringing a real touch of charm to spaces.

Decorative frames

Polyurethane foams are widely used to manufacture decorative frames for windows, doors, mirrors, and picture frames. They are also utilized in the production of balcony ledges and stair railings.

Chair legs and sofa crowns

Polyurethane decorative foam is integral to the production of sofa frames and chair legs. While lightweight, this foam is sturdy enough to tolerate daily use and weight. Its resistance to moisture and environmental factors, combined with its eco-friendliness and design versatility, has made it a favorable in the furniture and upholstery industry.

Sculpture making

Thanks to its unique properties, polyurethane decorative foam has gained popularity in the sculpture-making field. This material allows artists and designers to create lightweight, durable sculptures with intricate details.

Advantages of decorative foam

Polyurethane wood foam offers a variety of benefits that make it a top choice over other common decorative materials, including:

Lightweight

One of the biggest benefits of decorative foams is their light weight, which eases installation and handling. This is especially important for decorations that placed at height.

High strength

Even though it is lightweight, this foam can be produced in a wide range of densities, ensuring the durability of the finished products.

Moisture and heat resistance

Polyurethane decorative foams are highly resistant to moisture and heat, making them perfect for use in humid areas like bathrooms or kitchens.

High flexibility

Polyurethane is very moldable and can be easily shaped into various designs, allowing designers to craft unique decorative features.

Impact and abrasion resistance

In addition to being lightweight, decorative foams are also highly resistant to impact and abrasion, making them ideal for high-traffic areas such as hallways or commercial spaces.

Finishability

These foams are easy to finish and can undergo various post-processing treatments based on project requirements, such as sanding, priming, painting, cutting, or even screwing and riveting.

Polyurethane wood foam production by Imen Polymer Chemie and how to purchase

We at the Imen Polymer Chemie as a leading producer of polyurethane raw materials in Iran, have launched an innovative product called polyurethane wood foam/wood imitation polyurethane foam. This product, crafted with advanced technology and high-quality materials, serves as an excellent alternative to natural wood and finds extensive applications in the automotive, furniture, and interior design sectors.

Distinctive features of Imen Polymer Chemie’s polyurethane wood foam

Lightweight and high strength

The polyurethane wood foam from Imen Polymer Chemie is designed to be lightweight yet strong, making it a fantastic substitute for natural wood in various decorative applications.

Durability and longevity

This foam is resistant to moisture, heat, and different weather conditions. Unlike natural wood, which can warp due to environmental factors, polyurethane foam offers remarkable durability. Additionally, customers can request flame retardant additives to be included in the foam’s formulation, enhancing its fire-resistant qualities.

Workability and paint compatibility

Polyurethane wood foam is easy to work with and compatible with a wide range of paints, enabling the creation of diverse and unique designs.

Eco-friendly

One of the main benefits of this foam is that it helps reduce the use of natural wood, which in turn helps protect natural resources. Its environmentally friendly production process is also a significant advantage.

Design flexibility

This foam can be easily molded into different shapes, giving designers and manufacturers the flexibility to bring their creative ideas to life. It fits molds well, making it possible to produce even the most detailed designs.

Experience the best quality with Imen Polymer Chemie

Superior raw material quality

We use the finest raw materials in the production of our polyurethane foams, ensuring the final product’s quality.

Technical support and after-sales service

We provide technical consultation to help customers select the right product and execute their projects.

Advanced production technology

The use modern technology in our company’s production line allows our foam materials to compete in terms of quality and durability with international counterparts.

Competitive pricing

Since we produce our polyurethane wood imitation foam domestically, the product is offered at a more competitive price compared to imported alternatives, without compromising on quality.

How to purchase polyurethane wood imitation foam

To purchase polyurethane wood imitation foam, you can visit Imen Polymer Chemie’s official website or contact us directly. Our experts are always ready to provide services and products to customers. Additionally, products can be customized according to the needs of various projects.

To purchase this product and benefit from professional support, contact Imen Polymer Chemie today at (00982157325) and start your projects with certainity.

Conclusion

With its unique features, polyurethane wood imitation foam is recognized as a versatile material in the decorative and architectural industries. This polymer is resistant to moisture, heat, and temperature fluctuations, and can accept various coatings and finishes. Furthermore, it can be quickly molded and produced, making it ideal for urgent and large-scale projects. Polyurethane decorative foam also boasts a long lifespan and is suitable for both indoor and outdoor uses.

Imen Polymer Chemie

Some of our latest

What is the best car refrigerator insulation?

What are aliphatic isocyanates?