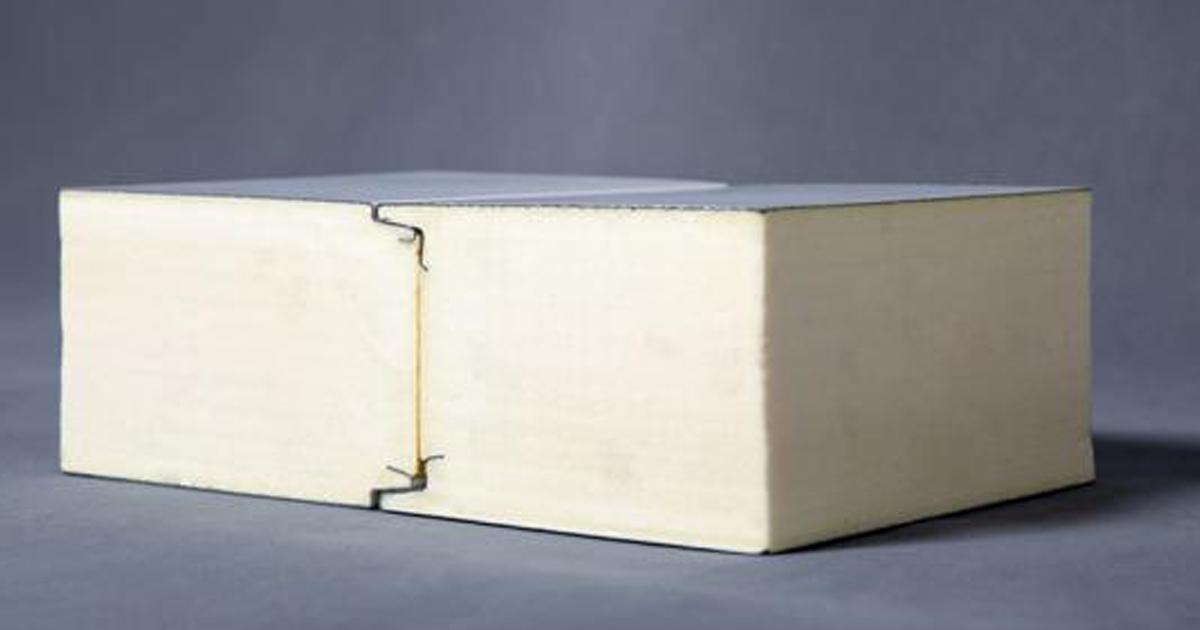

Rigid foam

Rigid polyurethane foam is a polymeric insulator where the ratio of polyol components significantly affects the final properties of the foam. The first key factor in these foams is the cross-link density of the polymer network, which ensures the final strength of the foam. In other words, rigid polyurethane foam has a closed-cell structure with high cross-linking and is a thermoset material with low density. This product is used in thermal insulation applications such as refrigerators and freezers, building insulation, pipes, refrigerated vehicles, and more. Therefore, rigid polyurethane foams play a crucial role in energy conservation.

Applications of rigid polyurethane foam

Due to the variety of properties and benefits, they have wide applications in various industries. Some of the most important applications of rigid polyurethane foam are:

- Building insulation

- Shoe soles and insoles

- Wire harnesses

- Office chair handles

- Bicycle and motorcycle seats

- Air filter foam

- Boxing gloves

- Car seats

- Refrigerator insulation

- Pillows and mattresses

After-sales services

We never leave you

on your own afterwards either

A complete guide to rigid polyurethane foam

Polyurethane has had a huge impact in our lives since its invention. It has unique properties that set it apart from other materials. Among various types of polyurethane foams, rigid foams are the most widely used. They have various applications in different industries.

In this article, we will discuss the foam’s characteristics and explain why it has become so popular in the market. Also, we introduce reliable polyurethane raw material manufacturer for those who want to buy high-quality materials.

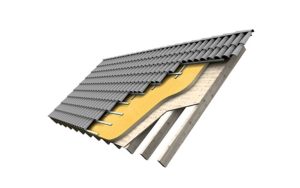

Rigid polyurethane foam for insulation and construction

Rigid polyurethane foam (RPUF) is mostly used as a thermal insulation material because of its great insulating capability, low thermal conductivity, and excellent dimensional stability. It is the preferred material for insulating gas pipes, building walls, ceilings, and refrigerated storage units. Its high compressive strength, low moisture absorption, and resistance to various chemicals make it a reliable solution for long-term applications. In other words, RPUF is the most energy saving material that’s why it is multi-functional in industries.

A trusted manufacturer of rigid polyurethane foam in the Middle East

Imen Polymer Chemie began its journey in 2003 by importing polyurethane materials and soon developed as one of the most outstanding domestic manufacturers of polyurethane raw materials in Iran.

It doesn’t matter if you need materials for spray foam or molded insulation panels, we can make you sure that you get reliable quality and helpful support every step of the way. We understand that when you’re buying rigid polyurethane foam raw materials from outside the country, it’s important to work with someone you can trust. With years of experience and a strong commitment to customers, we at Imen Polymer Chemie are here to make the process easy and dependable.

Exporting raw material of rigid polyurethane foam from Iran

One of Imen Polymer Chemie’s key strengths is our ability to meet the high standards needed for international trade. Our company follows strict quality checks, cares about environmental safety, and has clear paperwork processes to make exporting smooth and easy. If you’re looking to import raw materials for making rigid PU foam, or other PU materials, you can trust us for reliable quality, compliance with regulations, and on-time delivery.

Moreover, we also share complete technical documents, safety data sheets (SDS), and performance test results for every product. This transparency in work builds trust and help our international partners to be sure that they will receive high-quality products and also the knowledge needed to use them the right way.

Custom polyurethane formulations

Every industrial application has its unique needs, so creating a custom urethane formula is of great importance. This is why our company invests and pays a lot of attention to research and development (R&D).

Whether you want fire-resistant formulations for construction, hydrolysis-resistant coatings for marine applications, or low-density systems for lightweight insulation panels, Imen Polymer Chemie can provide personalized support from small scale testing (lab test) to full-scale production. In better words, we can develop specialized polyurethane systems that precisely match customer’s needs.

Our technical team work closely with customers to analyze raw material behavior, determine ideal processing parameters, and ensure that the final product meets all physical, mechanical, and environmental specifications. This level of technical partnership is especially valuable to international buyers who are unfamiliar with regional climatic conditions or local manufacturing limitations.

How to buy polyurethane raw materials from Imen Polymer Chemie

As global demand for durable and high-performance polymer systems continues to rise, choosing a reliable polyurethane raw material manufacturer becomes really important. Imen Polymer Chemie, a leading Iranian producer with deep experience in polyurethane systems, offers tailor made solutions to global markets seeking high-quality materials such as rigid polyurethane foam, adhesives, coatings, and more.

With decades of specialized experience and a strong focus on research and innovation, we are ready to serve international industries looking for superior quality and dependable supply.

Imen Polymer Chemie also participates in almost all famous industrial PU exhibitions and trade missions, to make it easy for international buyers to contact and explore collaboration opportunities in person.

Competitive advantages of working with Imen Polymer Chemie

When choosing a polyurethane raw material manufacturer, price and availability really matters. Moreover, long-term reliability, innovation, and responsiveness come into consideration. Also, Imen Polymer Chemie offers several distinct advantages:

Customized solutions:

Every customer receives a tailored formulation that matches their process, product, and climate.

Technical support:

From cup tests to equipment training, our company offers full technical guidance to ensure optimal product performance.

Consistent quality:

Automated reactors and rigorous testing ensure consistency in batch production.

Sustainable practices:

We adhere to environmental regulations and try to develop more eco-friendly systems (we already have developed many water based formulations).

Proven experience:

With over 20 years of operational history, we have the experience and production capacity to handle complex international projects.

These strengths make our company a preferred partner for businesses that value high-quality polyurethane systems and a dependable supply chain.

Conclusion

Imen Polymer Chemie offers more than just polyurethane raw materials, it delivers expertise, innovation, and trust. As a pioneer polyurethane manufacturer who is growing global reach, we invite international customers to experience the difference that a specialized and responsive supplier like us can make.

If your business is searching for a trustworthy partner to source rigid polyurethane foam systems, polyurethane adhesives, or other high-performance raw materials, we are here to meet your needs. Contact us today to find out more about how we can support your production goals and help you succeed in the global polyurethane market.