Table of contents

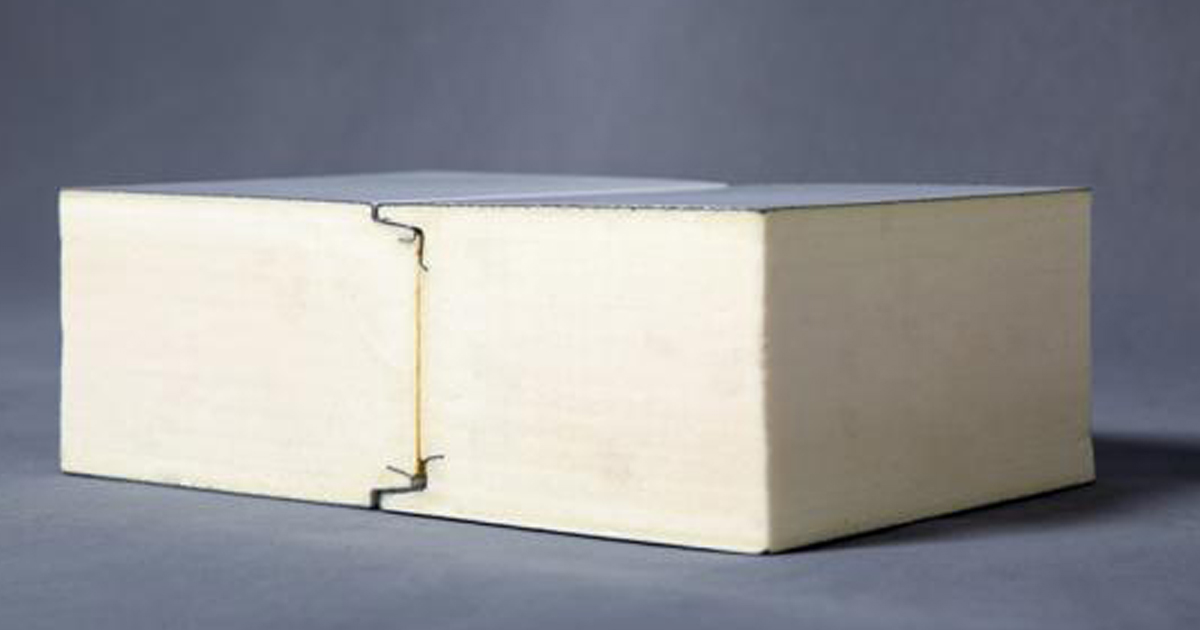

Polyurethane foam

Polyurethanes are polymers characterized by urethane bonds (-NH-CO-O-) in their structure. They are formed by the reaction of isocyanates with hydrogen-active compounds, such as polyols containing hydroxyl groups. Catalysts are typically used in the reaction process to enhance production speed and efficiency. Additionally, various additives are incorporated to achieve the desired properties.

The wide range of hydrogen-active compounds and diisocyanates enables the production of diverse polyurethanes. This variety allows manufacturers to customize polyurethane properties for specific applications using suitable materials and additives, delivering products tailored to customer needs.

Polyurethanes can be produced as rigid, flexible, or semi-rigid/semi-flexible foams. Because of their various forms and characteristics, they are used in different applications.

Raw materials for producing the best polyurethane foam

Raw materials play a key role in determining the quality and performance of polyurethane foam. As a result, raw materials (components) of polyurethane foam must be chosen carefully to ensure the final foam has a uniform structure, suitable physical and mechanical properties, and long-term stability.

Additives also significantly enhance the features of polyurethane foam. For instance, catalysts control the reaction speed, stabilizers maintain the cellular structure, and flame retardants improve safety in sensitive applications. Careful selection and balance of these additives help produce foam that performs optimally under diverse conditions.

By using high-quality raw materials and advanced formulations, companies like Imen Polymer Chemie manufacture products in accordance with global standards. This approach not only ensures product quality but also enhances competitiveness in domestic and international markets.

Key features of the best polyurethane foam

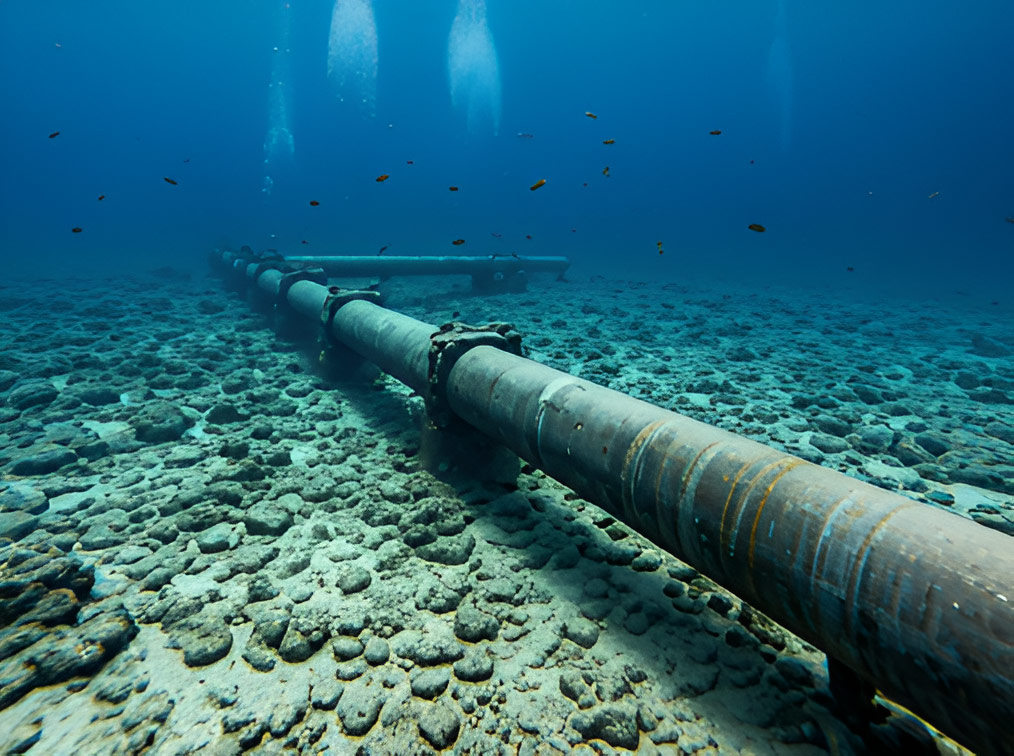

When discussing the best polyurethane foam, several characteristics come into play. In addition to high-quality raw materials, a uniform cellular structure suited to its application and resistance to various environmental conditions are crucial. One of the most critical features of high-quality polyurethane foam is its mechanical strength, particularly its resistance to pressure and tension. This property is especially vital in industries such as automotive and furniture, where products must tolerate repeated loading while maintaining durability and performance. Advanced foam formulations effectively meet these requirements. Furthermore, polyurethane foams, because of their cellular structure, excel in preventing heat and sound transfer. This property is essential for applications such as building insulation, industrial equipment, and heating and cooling systems.Why polyurethane foam outperforms other materials?

Polyurethane foam has remarkable competitive advantages due to its unique properties. One of the most remarkable benefits is its lightweight nature compared to its strength and durability, making it an ideal material for industries such as automotive and aerospace, where weight reduction is of great importance. Another advantage is the materials insulation property. Polyurethane foam effectively prevents heat and sound transfer, making it highly desirable in industries like construction and industrial equipment manufacturing. Compared to other materials like polystyrene foams or mineral fibers, polyurethane foam offers better efficiency (minimum thermal conductivity) and greater longevity. Its flexibility and adaptability to different conditions are additional benefits. Polyurethane foam can be produced in flexible, semi-rigid, and rigid forms, each tailored for specific applications. Adjusting the formulation to meet customer demands requires advanced technical expertise, making it a top choice across industries.Applications of polyurethane foam in industries

Polyurethane foam is widely used across various industries and is present in numerous everyday applications. In the construction industry, it serves as insulation for walls and roofs and is used in manufacturing insulated windows and doors. In the automotive sector, polyurethane foam is utilized for car seats and other interior components, including air filter foams, ensuring comfort and safety for passengers. It is also a preferred material in the furniture industry due to its formability and durability, making it suitable for producing sofas and other household items. Additionally, in the electronics industry, polyurethane foam acts as an electrical insulator and protective material for sensitive equipment. These extensive and diverse applications highlight polyurethane foam’s critical role in advancing product quality across various industries.

Comparing rigid and flexible polyurethane foams (quality and performance)

Polyurethane foams generally fall into two categories: flexible and rigid. The main difference lies in their structure and physical properties. Flexible foams typically feature open cells, which effectively absorb pressure, while rigid foams have closed-cell structures, offering enhanced strength and resistance to pressure and impact. These differences make each type of foam suitable for specific industrial needs. Understanding the features and differences between polyurethane foams aids in selecting the most appropriate type for particular applications, ultimately improving product quality and performance. Moreover, the formation of the cellular structure is critical. Foams with poor cellular structures are prone to environmental stresses and lack durability. The quality and performance of both foam types heavily depend on formulation and production processes. Manufacturers equipped with advanced technology and expertise can deliver high-quality foams with optimal performance.High-quality polyurethane foam reduces costs

Using high-quality polyurethane foam can significantly reduce long-term costs. Its durability and resistance to pressure, tension, and environmental changes minimize the need for frequent repairs or replacements. Additionally, polyurethane foam’s thermal and sound insulation properties contribute to energy savings. For example, its use in building or industrial equipment insulation reduces energy consumption for heating and cooling. This not only lowers operational costs but also keeps natural resources and reduces environmental impact.After sales service

For price inquiries and purchasing liquid polyurethane for polyurethane foam production, please contact Imen Polymer Chemie Company.

Sustainable and environmentally friendly foam

Nowadays, where environmental concerns are becoming increasingly important, choosing materials that are eco-friendly has become a top priority. Polyurethane foam is no exception. Producing sustainable and environmentally friendly foams requires raw materials that have minimal environmental impact. Imen Polymer Chemie, leveraging advanced technologies, has developed formulations that significantly reduce greenhouse gas emissions.

In fact, paying attention to environmental standards and sustainability principles plays a critical role in selecting various types of foam. Foams produced using eco-friendly formulations not only minimize negative effects on ecosystems but are also safer and healthier options for humans. These foams utilize raw materials and production processes that cause minimal harm to the environment, representing a significant step toward sustainable development and the preservation of natural resources.

One of the significant features of environmentally friendly foams is their recyclability. These foams can be reintroduced into the production cycle after their useful life or decomposed in ways that cause minimal harm to the environment. Additionally, the use of renewable raw materials and non-toxic catalysts in their production is an effective way to reduce environmental damage. Sustainability in foam production not only offers environmental benefits but is also economically advantageous.

How to choose the best polyurethane foam?

Selecting the best polyurethane foam involves carefully evaluating specific needs and usage conditions. This evaluation includes defining the type of application, environmental conditions, and the desired properties of the foam. For example, in industrial applications, foams with high mechanical resistance and a fine cellular structure are essential, while in the furniture industry, flexibility and softness are more critical.

To make an informed choice, start by identifying the application. Is the foam needed for thermal insulation, or will it be used as a component in consumer products? Each application demands different foam properties. For instance, closed-cell foams are better suited for insulation, while open-cell foams do great in applications requiring softness and flexibility.

Environmental factors such as temperature, humidity, and chemical exposure also play a crucial role. Foams used in high-temperature environments or in contact with chemicals must have appropriate thermal and chemical resistance. Therefore, selecting the right foam requires a complete understanding of your needs and consulting with expert manufacturers.

Some of

Polyurethane Products

Imen Polymer Chemie: A pioneer in polyurethane foam materials

Imen Polymer Chemie, as one of the pioneers in the production of polyurethane foam materials, plays an important role in meeting various industrial and construction needs. With a focus on technical expertise and modern technologies, the company produces a wide range of polyurethane foam materials tailored to specific customer needs. By relying on quality and environmental standards, our company aims to deliver products that are not only functionally superior but also environmentally responsible.

We are committed to continuous research and development to meet the growing demands of the market and improve product quality. Through innovative solutions, we enhance the performance and efficiency of polyurethane foams. Additionally, we provide specialized consultation and technical polyurethane support, ensuring customer confidence throughout every stage of their projects.

Conclusion

Polyurethane foams can be produced in rigid or flexible forms by changing their chemical composition, density, structure, and raw materials. Raw materials play a critical role in the quality and performance of polyurethane foam. Therefore, choosing high-quality polyurethane foam from manufacturers that use advanced technologies and premium raw materials can be a smart investment. If quality, durability, and operational cost reduction are your priorities, we at Imen Polymer Chemie Co. are ready to meet your needs with superior-performing polyurethane raw materials at competitive prices.