Thermal insulation spray foam

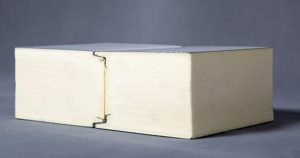

Rigid foam

Product codes

Related industries

Some advantages of thermal insulation polyurethane spray foam:

- Excellent thermal insulation

- Good mechanical strength

- Strong adhesion to various surfaces

- High durability

- Resistance to biological effects, solvents, and chemicals

- Prevention of pest infestation in walls

- Continuous surface coverage

Imen Polymer Chemie

Some of our latest

Spray polyurethane foam roofing

Roof sandwich panels and their different types

After-sales services

We never leave you

on your own afterwards either

Polyurethane thermal insulation spray foam

Polyurethane thermal insulation spray foam is a highly effective and widely used insulation material in various industries, particularly in construction, refrigeration, and industrial applications. Known for its superior thermal resistance, seamless application, and energy efficiency, polyurethane spray foam has become a preferred choice for insulation needs. This article explores its composition, benefits, applications, installation process, and considerations for better use.

Understanding polyurethane spray foam insulation

Open-cell polyurethane foam

Closed-cell polyurethane foam

Denser and more rigid, providing superior thermal resistance, moisture control, and structural support.

Advantages of polyurethane spray foam for thermal insulation

Thermal insulation with polyurethane spray foam has multiple advantages over common insulation materials; including the following:

1. Exceptional thermal insulation

Polyurethane spray foam has one of the lowest thermal conductivity values among insulation materials, making it highly effective in reducing heat transfer. The closed-cell structure minimizes air movement, preventing heat loss in winter and heat gain in summer.

2. Seamless and airtight barrier

Unlike traditional insulation materials, spray foam expands upon application, filling gaps, cracks, and irregular surfaces. This seamless application eliminates thermal bridging and prevents air leakage, enhancing energy efficiency.

3. Energy efficiency and cost savings

By reducing heat loss and improving HVAC system performance, polyurethane spray foam contributes to lower energy consumption and utility costs. Over time, the initial investment in spray foam insulation can result in significant savings on heating and cooling expenses.

4. Moisture and water resistance

Closed-cell polyurethane foam is highly resistant to water absorption, preventing mold growth and moisture-related damage. This property makes it ideal for humid environments and areas prone to water infiltration.

5. Structural strength and durability

The rigidity of closed-cell polyurethane foam adds structural integrity to buildings and surfaces. It enhances the strength of walls, roofs, and other insulated areas, making structures more resistant to environmental stress.

6. Soundproofing capabilities

Open-cell polyurethane spray foam has excellent sound-absorbing properties, reducing noise transmission within buildings. It is often used in residential and commercial spaces to enhance acoustic insulation.

7. Ease of application

Spray foam insulation is easily applied and this make it a preferred choice for many property owners.

Applications of polyurethane thermal insulation spray foam

The material contributes to reducing heating and cooling costs, thereby enhancing the overall sustainability of building structures; consequently, it has become popular in various construction applications including:

1. Residential and commercial buildings

Spray foam insulation is widely used in walls, roofs, ceilings, and floors to enhance energy efficiency and indoor comfort. It is suitable for both new construction and retrofitting projects.

2. Roofing and attic insulation

Polyurethane foam is used in roofing applications to create a waterproof and thermally insulated barrier. It enhances roof durability while improving overall building energy efficiency.

3. Pipelines and equipment insulation

Industries use spray foam insulation to insulate pipelines, storage tanks, and industrial equipment, minimizing heat loss and ensuring operational efficiency.

How to apply polyurethane spray foam insulation?

The application of polyurethane spray foam requires expertise and proper safety measures. The process involves the following steps:

1. Gather necessary equipment and safety gear

Before starting the spray foam application, ensure you have all the required equipment, and protective gear such as clothing, face mask and etc.

2. Prepare the surface

Proper surface preparation is essential to achieve a durable bond between the foam and the substrate. Ensure the area is free of dust, dirt, grease, or any other contaminants.

3. Set up the spray foam equipment

Setting up your spray foam equipment correctly is vital to achieve a smooth, even application. Also, Testing the spray gun before applying foam to your surface is essential for ensuring an even application.

4. Apply the spray foam

Applying the foam correctly is the key to achieving a seamless thermal barrier. You should begin spraying from the top of the surface and work your way down. Apply foam in several thin layers, rather than one thick layer and keep the spray gun moving at a steady pace to avoid buildup or gaps in the foam.

5. Allow the foam to cure

After applying the foam, it’s essential to give it time to cure and expand.

6. Clean up and dispose of materials properly

Proper cleanup is essential to maintaining safety and ensuring all materials are disposed of responsibly.

Why choose Imen Polymer Chemie’s thermal insulation spray foam?

For top-quality thermal insulation, our polyurethane raw materials provide excellent spray foam solutions. Here’s why our insulation materials are the ideal choice for your projects:As a trusted polyurethane raw material supplier, we offer high-performance, customized polyurethane solutions that meet the demanding requirements of the automotive sector. Contact us today to discover how our polyurethane materials can enhance your automotive products and manufacturing processes. Buying automotive polyurethane from Iran? Call +982157325

1. Superior thermal efficiency

Our spray polyurethane foam (SPF) systems are engineered to deliver exceptional thermal resistance (low λ-value), reducing heat transfer and enhancing energy efficiency. This results in lower energy consumption and significant cost savings for buildings, industrial applications, and cold storage.

2. Seamless and airtight insulation

Unlike traditional insulation materials, our spray foam expands and adheres seamlessly to surfaces, eliminating gaps and preventing air leakage, moisture intrusion, and thermal bridging. This provides excellent insulation and helps maintain a stable indoor climate.

3. Customized formulations for various climates

4. Fire-retardant and safe

Our insulation systems are developed with fire-retardant additives, enhancing building safety. The materials comply with international fire safety standards, providing added protection against potential fire hazards.

5. Strong adhesion and versatility

Imen Polymer Chemie’s spray foam bonds effectively to various surfaces, including concrete, metal, wood, and roofing materials. Its versatility makes it ideal for residential, commercial, and industrial applications, such as warehouses, pipelines, and transportation.

6. Long-lasting and sustainable solution

7. Technical expertise and support

Beyond providing high-quality raw materials, Imen Polymer Chemie offers comprehensive technical consultation and support. We guide customers on the best application techniques, ensuring maximum efficiency and product performance.

In other words, choosing Imen Polymer Chemie’s spray polyurethane foam material means investing in quality, efficiency, and reliability. Whether you need insulation for buildings, pipelines, or specialized industrial applications, our advanced polyurethane solutions ensure superior performance and long-term benefits.

Get in touch today to learn more about our custom formulations and how they can optimize your insulation projects.

Conclusion

Polyurethane thermal insulation spray foam is a versatile, high-performance insulation material that offers superior thermal resistance, energy efficiency, and durability. Its seamless application and moisture-resistant properties make it an ideal choice for various residential, commercial, and industrial applications. While professional installation and safety precautions are necessary, the long-term benefits, including cost savings and improved building performance, make polyurethane spray foam a valuable investment in insulation technology.

By selecting high-quality polyurethane materials and adhering to best practices, industries and homeowners can achieve efficient and sustainable insulation solutions that enhance comfort and reduce energy consumption.