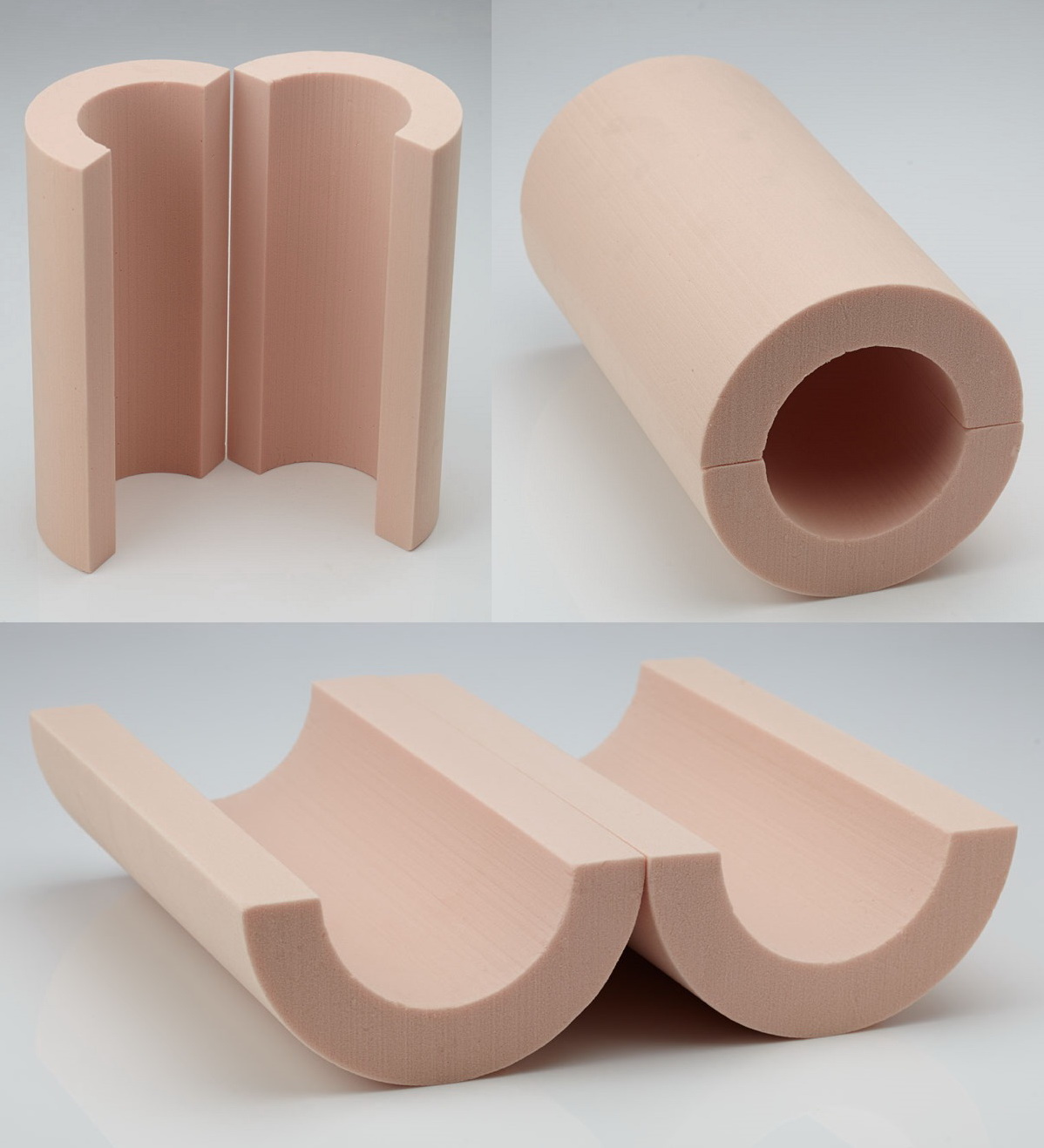

Pipe insulation foam (Polyisocyanurate foam)

Rigid foam

The most important feature of a thermal insulating material is its low thermal conductivity or, in other words, high thermal resistance. The use of polyurethane foam as an insulating layer around pipes not only maintains the heat inside the pipes and insulates them but also effectively prevents the penetration of moisture, water, and other corrosive fluids and gases into the insulation, as well as the growth and spread of microorganisms. In fact, these materials provide a seamless, integrated insulation that also protects pipes from mechanical damage.

Typically, polyurethane foam-insulated pipes have a dual-layer coating where the foam is applied to the pipe surface and protected by an outer layer, usually made of high-density polyethylene or aluminum foil. These insulations are lightweight and show good stability against abrasion and temperature changes.

Product codes

Related industries

Some advantages of polyurethane pipe insulation foam made in Iran:

- Excellent insulation performance (energy savings)

- Uniform density and seamless insulation

- High and stable strength

- Resistance to water and moisture

- Resistance to most petroleum products, chemicals, and solvents

- Outstanding corrosion resistance

Related Products

Imen Polymer Chemie

Some of our latest

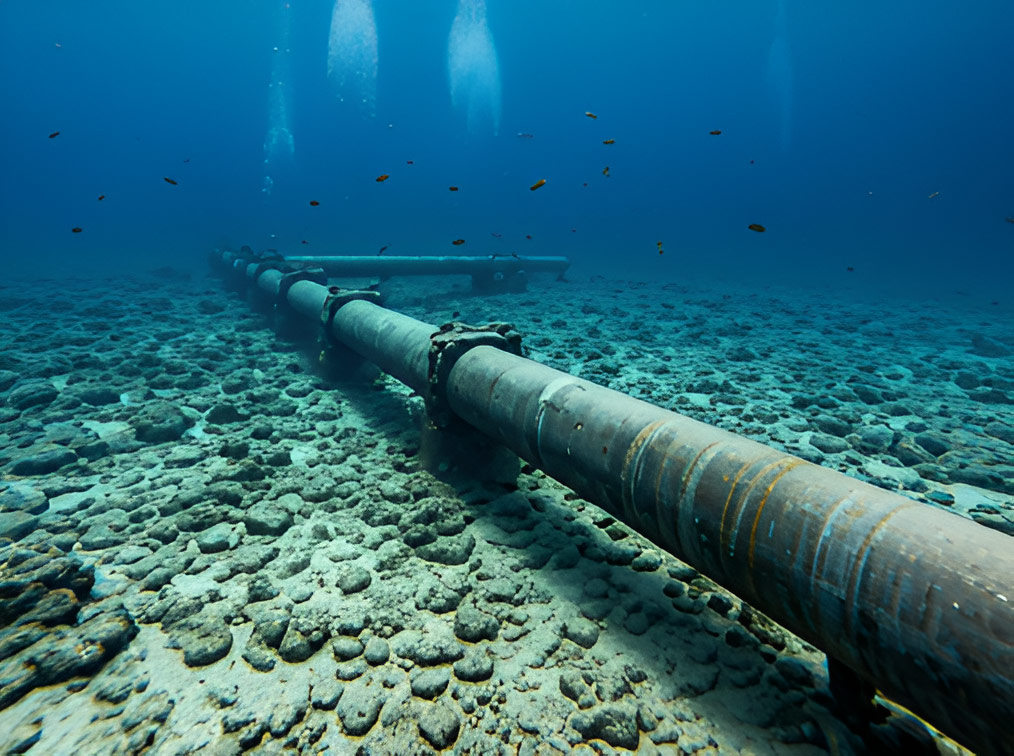

Subsea pipeline insulation

Optimizing electricity consumption in refrigerators with polyurethane insulation

After-sales services

We never leave you

on your own afterwards either

What is Pipe Insulation Foam?

Applications of Pipe Insulation Foam

Due to the variety of materials and characteristics, pipe insulation foam has widespread applications in various industries and is used for fluids such as water, steam, oil, chemicals, and gas. Here are some of its key applications:

Construction Industry

Insulating hot and cold-water pipes, sewage pipes, air conditioning ducts, and air ducts in residential, commercial, and industrial buildings.

Chemical Industry

Insulating chemical pipes, storage tanks, and reactors in chemical industries.

Oil and Gas Industry

Insulating oil and gas pipelines, storage tanks, and other equipment in upstream, midstream, and downstream oil and gas sectors.

Food and Pharmaceutical Industries:

Insulating pipes in food and pharmaceutical processing, storage tanks, and production lines.

Electricity and Electronics Industry

Insulating steam pipes, hot and cold-water transmission lines, and other equipment in power plants and electrical facilities.

Types of Pipe Insulation Foam

Pipe insulation foam is produced in various types in Iran, each with specific characteristics and applications. Some of the most common types include polyethylene foam, polystyrene foam, polyurethane foam, and elastomeric foams. Each of these types has unique properties, advantages, and disadvantages, which should be considered according to the industry’s needs. The import of pipe insulation foam from Iran typically involves identifying reliable suppliers, ensuring compliance with international standards, and managing shipping logistics efficiently. Below, the characteristics of each type are explained.

Polyethylene Foam

This foam is produced by polymerizing ethylene monomer and is a suitable thermal and sound insulator. Due to its high flexibility, resistance to moisture and chemicals, and affordable price, it has broad applications in various industries. Some of its main uses include pipe insulation, packaging for food and pharmaceuticals, sports mats, and underlays.

Polystyrene Foam

Polystyrene foam is a cheap and lightweight thermal insulator made from styrene monomer. It is produced in two forms: extruded foam (XPS) and expanded foam (EPS). Due to its affordability, light weight, and high efficiency, it has widespread applications in various industries such as building insulation, refrigerators, freezers, vehicles, and packaging.

Polyurethane Foam

Known as PUF, polyurethane foam is an expanded plastic with excellent thermal and acoustic insulation properties, resistant to moisture, and can be fire-resistant depending on its formulation. It comes in spray foam and pre-molded foam forms, and its varied density and cellular structure make it highly versatile.

Elastomeric Foam

Made from synthetic rubbers like ethylene propylene diene monomer (EPDM) and nitrile butadiene rubber (NBR), elastomeric foam offers excellent resistance to moisture, fire, and chemicals, though it is the most expensive option for pipe insulation. Its applications include insulating hot and cold-water pipes, sewage pipes, air conditioning ducts, and power plants.

Polyisocyanurate Foam (PIR)

Factors Influencing the Choice of Pipe Insulation Foam

Several factors can impact the quality and performance of pipe insulation foam. These include resistance to heat, insulation capacity, durability, ease of installation and maintenance, resistance to water penetration, cost, fire resistance, and environmental impact.

Advantages and Disadvantages of Pipe Insulation Foam

For each specific application, pipe insulation foam has its pros and cons. Some of its advantages include resistance to heat and environmental conditions, ease of installation, energy savings, and sound reduction. However, certain types of foam may lose flexibility under extreme temperatures and may require thicker layers for effective insulation.

Price of Pipe Insulation Foam in Iran

The price of pipe insulation foam depends on the type and quality of the product, pipe size, and market conditions. It is essential to also consider the installation and maintenance costs when evaluating the overall price.

Imen Polymer Chemie Company

Imen Polymer Chemie is a knowledge-based company in Iran that offers polyurethane-based pipe insulation materials. This company, with over 20 years of excellent experience, offers a wide range of pipe insulation grades for various applications in industries such as construction, home appliances, petrochemicals, and more. The main products of Imen Polymer Chemie include raw materials for polyurethane foams, which are used in different forms such as spray foam, molded foam, and cast foam. Utilizing high-quality raw materials and advanced technologies, the company produces products with superior quality, excellent insulation, high thermal efficiency, and competitive pricing. Imen Polymer Chemie is committed to providing innovative and sustainable solutions for the insulation needs of its customers. With an experienced research and development team, the company is continuously improving its products and production processes, striving to achieve sustainable development goals and environmental protection. Additionally, the company offers technical consultation and after-sales support to assist customers in selecting and using their products.

Frequently asked questions

Is imen Polymer chemistry a producer of pipe insulation?

Imen Polymer Chemie specializes in producing liquid polyurethane, a key material used in manufacturing pipe insulation foam. Their high-quality polyurethane ensures excellent insulation properties for various applications. For pricing inquiries on liquid polyurethane and consulting with the best Iranian polyurethane foam manufacturer, call +982157325

How to order liquid polyurethane from Iran?

You can order liquid polyurtane for pipe insulation from Iran by contacting Imen Polymer Chemie sales team directly. They offer tailored solutions, clear pricing, and streamlined processes for international orders.

Do Imen Polymer Chemie 's products have standard certifications?

Yes, the products have the relevant standard certifications, and all products are manufactured according to industrial standards and with high-quality raw materials.

What distinguishes Imen Polymer Chemie 's pipe foams from other products?

The raw materials for pipe insulation provided by Imen Polymer Chemie, like our other products, have been refined through years of experience and testing. Our products offer excellent durability in various environmental conditions over the long term and are of exceptionally high quality.

Is it possible to customize pipe insulation foam for use in different climate conditions?

Yes, it should be noted that our pipe insulation materials are designed and formulated in various grades for different geographical conditions. However, our researchers at Imen Polymer Chemie have the technical knowledge and capabilities to customize materials based on customer requests.