Wood imitation foam

Rigid foam

The excessive cutting of trees and deforestation have led to global warming and reduced rainfall. Additionally, due to the expansion of the decorative industry and the high cost of handmade decorative items, manufacturers in this industry are increasingly using various polymeric materials as alternatives to wood.

Polyurethane wood imitation foam has many advantages over natural wood, making it popular in the wood and furniture industries. This product is offered in various densities ranging from 100 to 1000 kg/m³ by Imen Polymer Chemie Company. These systems can also be designed with flame-resistant properties.

Product codes

Related industries

Some advantages of polyurethane wood imitation foam

- Environmental protection by preventing deforestation

- High-speed production

- Resistance to decay and mold growth

- Easy maintenance (high durability)

- A wide range of density, from 100 to 1000 kg/m³

- Favorable physical and mechanical properties

- Lightweight, reducing transportation costs

- Paintable surface

- Can be drilled, riveted, and sawed

Imen Polymer Chemie

Some of our latest

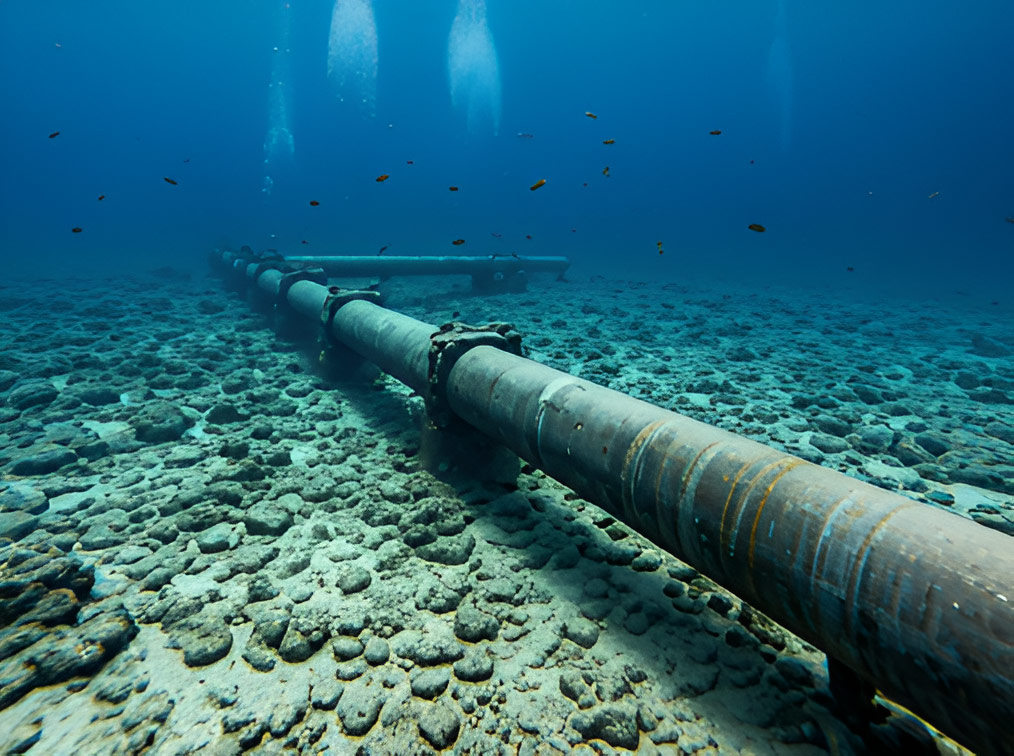

Subsea pipeline insulation

Optimizing electricity consumption in refrigerators with polyurethane insulation

After-sales services

We never leave you

on your own afterwards either

Polyurethane wood-imitation foam: a smart choice for enhanced beauty and durability

Polyurethane wood-imitation foams (imitation wood foams), as one of the modern innovations in the building materials and interior decoration industries, have secured a special place in the market. These products, with their appearance resembling natural wood and superior physical properties, are recognized as a suitable alternative to natural wood. In this content, we will provide a comprehensive introduction to polyurethane imitation wood foam and discuss its advantages over similar materials.

What is polyurethane wood-imitation foam?

Polyurethane wood-imitation foam is a lightweight and durable material produced using a specific chemical combination of polyurethane. Due to its resemblance to natural wood, this product can be used as a substitute in both interior and exterior decoration. Polyurethane foam is produced by injection molding and can easily be shaped into various forms and dimensions. In other words, polyurethane wood foam materials can be poured into molds either manually or mechanically, and after the curing process, the final product takes the desired shape of the mold.

Advantages of polyurethane wood-imitation foam

This polyurethane foam has numerous benefits that have contributed to its growing popularity across many industries. Below are some of these advantages:

High Durability and Strength

One of the main advantages of polyurethane wood-imitation foam is its high durability. This product is resistant to moisture, heat, and weather changes, and does not fade or crack over time. These characteristics make it an ideal choice for use in high-moisture areas or outdoor spaces. Additionally, unlike natural wood, this foam does not easily suffer mechanical damage due to its strength, and its properties can be enhanced by adjusting the foam’s formulation.

Lightweight and Easy Installation

Thanks to its lightweight nature, polyurethane foam is easy to install without the need for heavy or complicated tools. This reduces installation costs and shortens project timelines.

Thermal Insulation

Due to its closed-cell structure, polyurethane wood-imitation foam acts as an excellent thermal insulator. It effectively retains indoor temperatures and prevents heat loss or transfer to the external environment.

Natural Appearance and Aesthetic Appeal

Polyurethane wood-imitation foams, with their appearance closely resembling natural wood, can enhance the beauty of both interior and exterior spaces. These products come in a variety of designs and colors, allowing designers and customers to choose the best option according to their tastes and needs. Furthermore, these foams can be easily colored and molded into various shapes for different applications.

Resistance to Rot and Pests

Unlike natural wood, which is susceptible to insects and fungi, polyurethane foam is resistant to such damage due to its specific chemical composition. This feature increases the product’s lifespan and reduces the need for frequent repairs and maintenance. Moreover, unlike natural wood, it resists decay, giving it a clear advantage.

Fire Resistance

Polyurethane wood-imitation foam can be formulated to provide excellent resistance to flames and combustion.

Simple Production Method

This foam can be easily molded, taking on the shape of the mold, which minimizes secondary processes in the final product’s production.

Environmental Protection

Excessive deforestation contributes to global warming and severe environmental damage. Since polyurethane wood-imitation foam mimics natural wood while offering superior properties, it is considered a more environmentally friendly option for decorative and other applications.

Applications of polyurethane wood-imitation foam

Given its remarkable characteristics, polyurethane foam has seen increasing popularity in various industries, with diverse applications, some of which include:

Interior Decoration

Polyurethane wood-imitation foam is widely used in the interior decoration of homes and commercial spaces due to its aesthetic appeal and unique properties. It can be utilized for prefabricated walls, prefabricated plaster, cornice, and even furniture frames or table and chair legs.

Building Facades

Owing to its high resistance to environmental and weather factors, polyurethane foam is an excellent option for building facades. Facades made with this foam not only offer aesthetic beauty but also greater durability.

False Ceilings

Due to its lightness and high formability, polyurethane foam is a suitable choice for creating false ceilings. These ceilings can be produced in various wood-imitation designs, adding elegance to the interior.

Architectural Molds and Decorative Features:

With its high moldability, polyurethane foam can be used to create architectural and decorative elements, easily replacing heavier materials like stone and wood. It also has the potential to bring significant changes to the sculpture industry.

Comparison of polyurethane wood-imitation foam with similar materials

Polyurethane wood imitation foam stands out in several ways compared to similar materials:

Compared to Natural Wood

While natural wood brings beauty and warmth to spaces, it requires continuous care and maintenance. Additionally, natural wood is prone to moisture, insects, and fungi. Polyurethane wood-imitation foam preserves the appearance and feel of natural wood while eliminating these issues.

Compared to Composite Materials

Composite materials like PVC and fiberglass are also proposed as alternatives to natural wood. However, they typically have an artificial appearance and cannot match the natural beauty and feel of polyurethane wood-imitation foam. Moreover, polyurethane foam is superior due to its better insulation and higher impact resistance.

Installation and maintenance of polyurethane wood-imitation foam

Installing polyurethane wood-imitation foam is very simple and quick. These products are usually attached to surfaces using special adhesives or basic screws. After installation, they require minimal maintenance and can maintain their aesthetic appearance for years with simple cleaning.

Why choose polyurethane wood-imitation foam?

Choosing polyurethane wood-imitation foam means opting for a product that not only mimics the beauty of natural wood but also offers unique features that are unmatched by any other material. With its numerous advantages and versatile applications, it is an ideal option for various construction and decoration projects.

Imen Polymer Chemie: A distinguished choice in polyurethane foams

Imen Polymer Chemie, a leading company in the production of polyurethane wood-imitation foams, has achieved success by utilizing modern technologies and specialized formulations to create high-quality products that meet international standards. One of Imen Polymer Chemie’s main distinctions compared to other manufacturers is its use of superior raw materials and strict process control, resulting in more durable and natural-looking products. Furthermore, Imen Polymer Chemie has earned customer trust by offering excellent after-sales services and technical support, making it a reputable brand in the polyurethane industry.

Conclusion

Polyurethane wood-imitation foam, as an innovative and high-quality product, has secured a special place in the construction and decoration industries. With its superb features over natural wood and other similar materials, it can be a smart choice for various projects. Imen Polymer Chemie, by producing high-quality polyurethane foams and offering outstanding services, is a reliable option for meeting your needs in this field.