Table of contents

This technology is not merely a surface covering; it is an integrated roofing and insulation system designed to enhance the overall performance of a building envelope. In recent years, architects, engineers, and contractors have increasingly turned their attention to polyurethane spray foam for roofing systems due to their proven technical advantages and compatibility with sustainable building standards. Understanding how spray polyurethane (PU) foam roofing works, what materials are involved, and how it compares with conventional systems is essential for making right decisions in both new construction and renovation projects. This article provides a comprehensive, scientifically grounded overview of SPF roofing, focusing on materials, performance, applications, and sourcing considerations, with a particular emphasis on polyurethane raw materials.

What Is spray polyurethane foam (SPF) roofing?

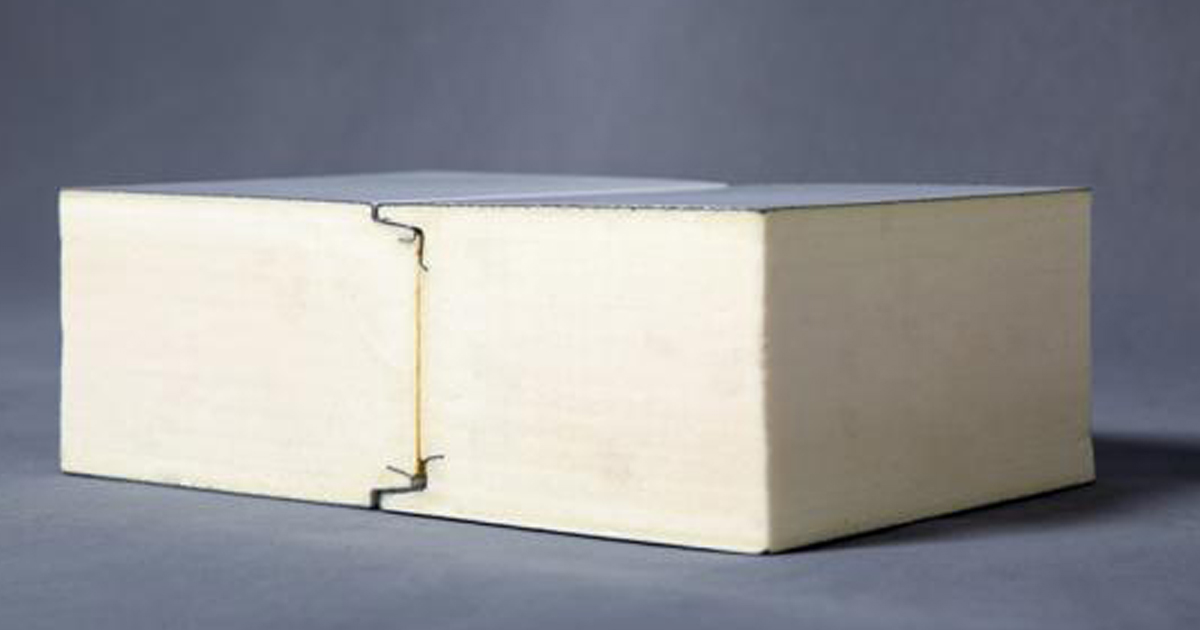

Spray polyurethane foam roofing is a system created by applying a liquid mixture of polyurethane components onto a roof surface, where it reacts, expands, and cures into a rigid or semi-rigid foam layer. This foam adheres directly to the substrate, forming a continuous, seamless layer without any joints, or fasteners. Once cured, the foam is typically protected with an elastomeric or polyurethane-based coating to shield it from ultraviolet radiation and environmental exposure.

From a technical point of view, SPF roofing functions as both insulation and air barrier. The closed-cell structure of heat insulation SPF commonly used in roofing applications provides high compressive strength and low water absorption, while also delivering excellent thermal resistance. Unlike traditional roofing systems that rely on multiple layers and mechanical attachments, this PU foam simplifies the roof assembly and reduces the number of potential failure points. This integrated nature is one of the early reasons SPF systems display long service life when properly designed and maintained.

Key benefits of spray polyurethane foam roofing systems

One of the most significant advantages of insulated foam roof system is their exceptional thermal performance. PU spray foam offers a high R-value per unit thickness, allowing designers to achieve superior insulation levels without any additional material buildup. This directly causes reduced heating and cooling loads, improved indoor comfort, and lower energy consumption throughout the building’s operational life.

Another key benefit lies in the seamless nature of the foam. Because the foam is sprayed in place and expands to fill gaps, it removes joints and penetrations that are common sources of air leakage and water intrusion in conventional roofs. This continuity enhances the building’s resistance to moisture-related damage, such as mold growth and structural deterioration. Additionally, this spray foam is lightweight compared to many traditional systems, making it suitable for strengthening existing roofs without adding significant additional loads on the structure.

Types of spray polyurethane foam used in roofing

Spray polyurethane foam used in roofing applications is generally categorized into closed-cell and, less commonly, open-cell formulations. Closed-cell SPF is the preferred choice for roofing systems due to its higher density, superior mechanical strength, and low permeability to water vapor. Its compact cell structure traps blowing agents within the cells, resulting in excellent insulating properties and enhanced resistance to moisture penetration.

The formulation of roofing-grade SPF is carefully engineered through precise combinations of polyols, isocyanates, catalysts, surfactants, and blowing agents. Adjusting these components allows manufacturers of PU raw materials to tailor foam properties such as density, reaction speed, dimensional stability, and adhesion.

How spray polyurethane foam roofing improves energy efficiency?

Energy efficiency is one of the defining characteristics of polyurethane spray foam for roofing systems. By creating a continuous insulation layer directly on the roof floor, the foam reduces thermal bridges that commonly occur in mechanically fastened or layered insulation systems. This continuity significantly reduces heat transfer through the roof, which is often one of the largest sources of energy loss in buildings.

In addition to thermal insulation, SPF contributes to energy efficiency through air sealing. Uncontrolled air leakage can explain a considerable portion of a building’s energy waste, as conditioned air escapes and unconditioned air enters the interior. SPF roofing effectively seals cracks, joints, and penetrations, limiting air infiltration and exfiltration. When combined with reflective or UV-resistant protective coatings, SPF systems can also reduce heat gain from solar radiation, further enhancing overall building performance.

Applications of spray polyurethane foam in roofing systems

Thermal insulation spray foam roofing can be used on many types of buildings, including residential, commercial, and industrial projects. SPF can be sprayed directly over existing roof surfaces like concrete, metal, or old bitumen roofs, which makes it a practical and time-saving option for roof repair and renovation without removing the old roof. It has to be mentioned that this spray foam roofing performs really well in situations where conventional roofing materials fail to provide proper sealing, insulation, or long-term performance.

This heat insulation roofing system is also a good choice for roofs with complex shapes, many pipes, or uneven surfaces. Because the foam is sprayed as a liquid and then expands, it easily fills gaps and covers hard-to-reach areas. This creates a continuous insulation and waterproof layer on the entire roof. Factories, cold storage buildings, warehouses, and production facilities often use spray-applied foam roofing because it is durable and helps keep indoor temperatures stable, even in demanding working conditions.

Spray polyurethane foam roofing vs traditional roofing materials

When spray polyurethane foam roofing is compared with traditional roofing systems such as built-up roofs, modified bitumen, or single-ply membranes, its advantages become easy to understand. Traditional roofs depend on seams, overlaps, and fasteners to stay in place, and these areas often become weak points over time. Roofing foam spray, on the other hand, creates one continuous layer that fully sticks to the roof surface. Because there are no seams, it is less likely to leak or be damaged as the building expands and contracts with temperature changes.

Although this insulation method may cost more at first, it saves your money in the long term. It lasts longer, can be easily repaired, and helps reduce energy bills by improving insulation. Instead of removing and replacing the entire roof, SPF systems can usually be renewed by adding a new protective coating. This extends the roof’s life, lowers maintenance costs, and produces much less waste compared to traditional roofing systems.

Factors to consider when choosing SPF roofing

When selecting a spray foam for insulating roofing system several important factors that are directly related to the project and its environment must be considered. Climate conditions are one of the most critical points to think about. Temperature levels, air humidity, and exposure to sunlight can strongly affect how the foam reacts during application and how well the protective coating performs over time. If these conditions are not properly considered during design and material selection, the roofing system may face performance issues in the long term. Roofing system spray foam must be adapted to the local climate so the foam cures properly and performs reliably over time.

Another key factor is the quality of the polyurethane raw materials used to produce the spray foam. High-quality materials provide consistent reaction behavior, stable physical properties, and reliable performance during application. This consistency helps contractors achieve uniform foam structure and predictable results on the roof. For this reason, contractors and system designers should work with trusted raw material suppliers who offer reliable products and also technical support, clear documentation, and the ability to adjust formulations when needed.

Polyurethane Products

Buying polyurethane materials from Iran for SPF production

Iran has become a reliable source of polyurethane raw materials for spray PU foam systems. Over time, local manufacturers have gained practical experience and improved their production processes. As a result, they are able to supply materials that work well in real SPF applications while keeping costs reasonable. This makes Iranian polyurethane materials a practical choice for SPF roofing producers who need both performance and cost control.

When purchasing PU materials from Iran, price should not be the only factor. Consistent material quality, stable production, and supplier support all affect how well the foam performs on the roof. Reliable suppliers help customers apply the foam correctly and avoid common application problems. Imen Polymer Chemie produces polyurethane raw materials with strict quality control and accurate formulations, working closely with SPF producers to support dependable results in roofing and other challenging applications.

Conclusion

Spray polyurethane foam provides a smart and practical solution to many of today’s roofing challenges. By combining insulation, air sealing, and waterproofing into a single continuous layer, this roofing system helps reduce energy loss, enhances durability, and adapts easily to a variety of roof designs. Compared to traditional methods, its advantages are obvious in long-term costs, performance on complex surfaces, and its contribution to more energy-efficient buildings.

The success of a polyurethane foam roof depends on proper application and also on the quality of the raw materials used to produce the foam. Selecting the right components and designing the system carefully are essential for achieving consistent, reliable results. With continuous advancements in polyurethane technology and access to high-quality raw materials from suppliers like Imen Polymer Chemie, foam-based roofing is increasingly becoming popular as a durable, energy-efficient, and great solution for modern construction.