Table of contents

These characteristics make them a preferred choice in applications where visual stability, surface quality, and long service life are essential. In recent years, the demand for high-performance coatings, adhesives, and specialty polyurethane systems has increased significantly. Understanding what aliphatic isocyanates are, how they are structured, and why they behave differently is essential for engineers, chemists, and industrial decision-makers. So, in this article, we simply explain these materials, their structure, main properties, common types, and where they are used in real industrial applications.

What is an aliphatic isocyanate?

An aliphatic isocyanate is a chemical compound that contains one or more isocyanate functional groups (–N=C=O) attached to an aliphatic or cycloaliphatic carbon chain. In simple terms, this means that the reactive NCO group is not directly connected to an aromatic ring. This structural difference is the main factor that separates aliphatic isocyanates from aromatic isocyanates and explains many of their unique properties.

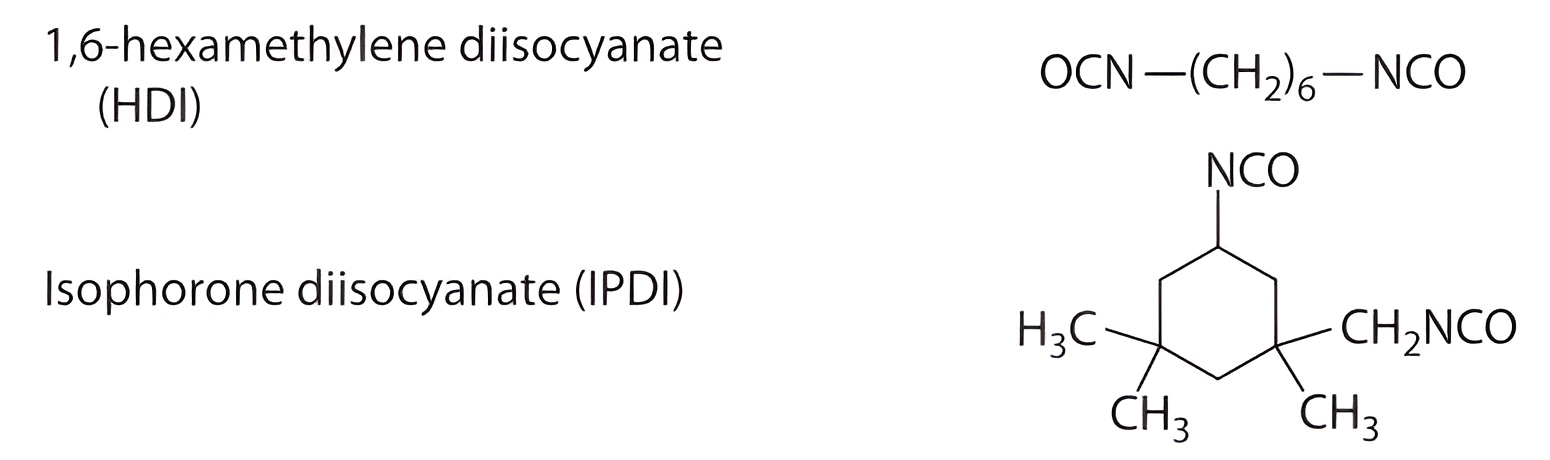

Well-known examples of aliphatic isocyanates include hexamethylene diisocyanate (HDI) and isophorone diisocyanate (IPDI). These compounds are widely used in polyurethane systems that require high resistance to ultraviolet light and long-term color stability. Unlike aromatic isocyanates, which tend to yellow or degrade when exposed to sunlight, aliphatic isocyanates maintain their clarity and appearance over time. This makes them especially valuable in applications where aesthetics and durability are equally important. In the following you can see their chemical structure.

Although aliphatic isocyanates are usually more expensive and slightly less reactive than aromatic ones, their performance advantages often justify the higher cost. Accordingly, in many advanced applications, choosing an aliphatic isocyanate is not just a material choice but an engineering decision based on quality, lifespan, and reliability.

Structure of an aliphatic isocyanate

The chemical structure of aliphatic isocyanates is based on the presence of the isocyanate group bonded to aliphatic carbon atoms. These carbon chains can be linear, branched, or arranged in saturated ring structures known as cycloaliphatic systems. This type of structure reduces the absorption of ultraviolet light, which is one of the main reasons for the excellent light stability of aliphatic isocyanates.

The arrangement of the NCO groups and the nature of the carbon backbone strongly influence the behavior of the isocyanate in chemical reactions. Factors such as reactivity, viscosity, curing speed, and compatibility with different polyols are all affected by the molecular structure. For example, linear aliphatic diisocyanates often show more uniform reactivity, while bulky or cyclic structures provide better control over reaction rates and final polymer properties.

In polyurethane formulation, this structural flexibility gives chemists a powerful tool. By selecting a specific aliphatic isocyanate structure, it is possible to adjust properties such as hardness, flexibility, chemical resistance, and surface finish. This level of control is one of the reasons why aliphatic isocyanates are so popular in different applications.

Application of an aliphatic isocyanate

Aliphatic isocyanates are used in a wide range of industries where long-term performance and resistance to environmental factors are required. One of their most important applications is in polyurethane coatings. These coatings are commonly used in automotive finishes, aerospace components, outdoor metal structures, and industrial equipment. In such environments, exposure to sunlight, moisture, and temperature changes is unavoidable, and maintaining color and surface quality is critical.

Beyond coatings, aliphatic isocyanates are also widely used in high-performance polyurethane adhesives. These adhesives offer strong bonding, good flexibility, and resistance to moisture and chemicals. As a result, they are used in construction, composite manufacturing, electronics, and transportation industries. Their stable performance over time makes them suitable for both structural and decorative bonding applications.

Another important area is specialty polyurethane systems, including certain types of flexible and rigid foams where dimensional stability and surface appearance matter. In these cases, aliphatic isocyanates help ensure that the final product maintains its shape, color, and mechanical properties throughout its service life. This makes them especially useful in premium products where quality standards are high.

Types of aliphatic isocyanates

Aliphatic isocyanates can be classified into several main categories based on their molecular structure and functionality. This classification is important because each type offers different performance characteristics and is suitable for specific applications. Understanding these differences allows formulators to choose the right raw material for their polyurethane systems.

- One major category is aliphatic diisocyanates. These compounds contain two reactive isocyanate groups and are among the most commonly used types. Because they have a relatively simple structure, they allow for controlled reactions with polyols and help create polyurethane networks with balanced mechanical properties. Aliphatic diisocyanates are often chosen when a good combination of strength, flexibility, and process control is required.

- Another important group is aliphatic polyisocyanates. These materials are usually produced by chemically modifying aliphatic diisocyanates to increase the number of NCO groups. The higher functionality leads to more crosslinked polymer networks, resulting in improved hardness, chemical resistance, and durability. Aliphatic polyisocyanates are widely used in high-performance coatings and protective systems where long-term resistance is essential.

- Cycloaliphatic isocyanates form a special subgroup within aliphatic isocyanates. Their structure includes saturated carbon rings, which provide an excellent balance between mechanical strength and light stability. These materials are often used in clear and glossy coatings where transparency and resistance to yellowing are critical. Because of their stable structure, cycloaliphatic isocyanates are especially popular in outdoor applications with strict quality requirements.

Overall, the wide variety of aliphatic isocyanates makes it possible to choose the right material for each industrial application, from coatings and adhesives to specialized polyurethane systems. This diversity allows manufacturers to achieve more predictable performance and better control over the final product properties. Therefore, selecting the appropriate type of aliphatic isocyanate should always be based on the specific requirements and expectations of the final polyurethane product.

Properties of aliphatic isocyanates

Aliphatic isocyanates are known for a combination of physical and chemical properties that set them apart from other isocyanates. As we mentioned before, one of the most important properties is their outstanding resistance to ultraviolet light. Products made with aliphatic isocyanates show minimal yellowing and surface degradation even after long-term exposure to sunlight. This property alone makes them highly valuable in applications where appearance matters.

Another key property is their good chemical resistance. Polyurethane systems based on aliphatic isocyanates can resist many chemicals, oils, and solvents, which helps maintain performance in harsh industrial environments. They also offer suitable thermal stability, allowing products to perform reliably over a wide temperature range.

Flexibility in formulation is another advantage. By adjusting the type and structure of the aliphatic isocyanate, manufacturers can control properties such as hardness, elasticity, gloss, and surface smoothness. This versatility allows aliphatic isocyanates to be used in both decorative and protective applications, making them a preferred choice for high-quality polyurethane systems.

Safety and storage considerations for aliphatic isocyanates

Aliphatic isocyanates are reactive chemical materials, and proper handling is essential to ensure both safety and product quality. One of the most important points is avoiding contact with moisture, as even small amounts of water can trigger unwanted reactions. These reactions may lead to increased pressure inside containers, changes in viscosity, or formation of solid particles, all of which can negatively affect performance during processing.

From a safety perspective, working environments should always be well ventilated, especially during handling and formulation. The use of basic personal protective equipment such as gloves, safety glasses, and suitable work clothing is strongly recommended. While aliphatic isocyanates are valued for their stability in final products, they must be treated carefully in their raw form. Following proper handling procedures, studying material safety and technical data sheets (MSDS and TDS) helps protect workers and ensures consistent results in industrial applications.

Storage conditions also play a critical role in maintaining material quality. Aliphatic isocyanates should be stored in tightly sealed containers, away from direct sunlight and sources of heat. A stable storage temperature, typically around room temperature, helps prevent degradation and extends shelf life. By following these simple but essential guidelines, manufacturers can maintain both safety standards and reliable material performance.

Polyurethane raw materials for different industrial applications

Polyurethane systems are used in many industries, and each application requires raw materials with specific performance characteristics. Coatings, adhesives, elastomers, and specialty systems all place different demands on polyurethane formulations. For this reason, selecting the right combination of raw materials, especially isocyanates, is a key factor in achieving consistent and high-quality results.

Different industrial applications may require properties such as flexibility, hardness, chemical resistance, or long-term visual stability. Aliphatic isocyanates play an important role in meeting these requirements, particularly in systems where appearance and durability are critical. However, no single isocyanate can meet all needs. Successful polyurethane production depends on matching the material selection to processing conditions and final product expectations.

Imen Polymer Chemie, as a famous producer of polyurethane raw materials, provides a range of solutions designed to support different industrial applications. By offering tailored raw materials and technical insight, manufacturers can develop polyurethane systems with reliable performance without unnecessary complexity in formulation. This approach allows producers to focus on product quality, process stability, and long-term value in their final applications.

Conclusion

Aliphatic isocyanates play a vital role in the development of advanced polyurethane materials. Their unique chemical structure gives them superior resistance to light, weathering, and environmental stress, making them ideal for applications that demand long-term performance and visual stability. Although in the first place they may cost you more compared to aromatic isocyanates, their technical advantages often worth it.

By choosing aliphatic isocyanates based on the real needs of each application, manufacturers can achieve stable results and strong long-term performance. These materials are widely used in industries where consistent quality and predictable behavior truly matter. As polyurethane applications continue to expand, aliphatic isocyanates remain a solid option for developing industrial systems that perform well over time.