Table of contents

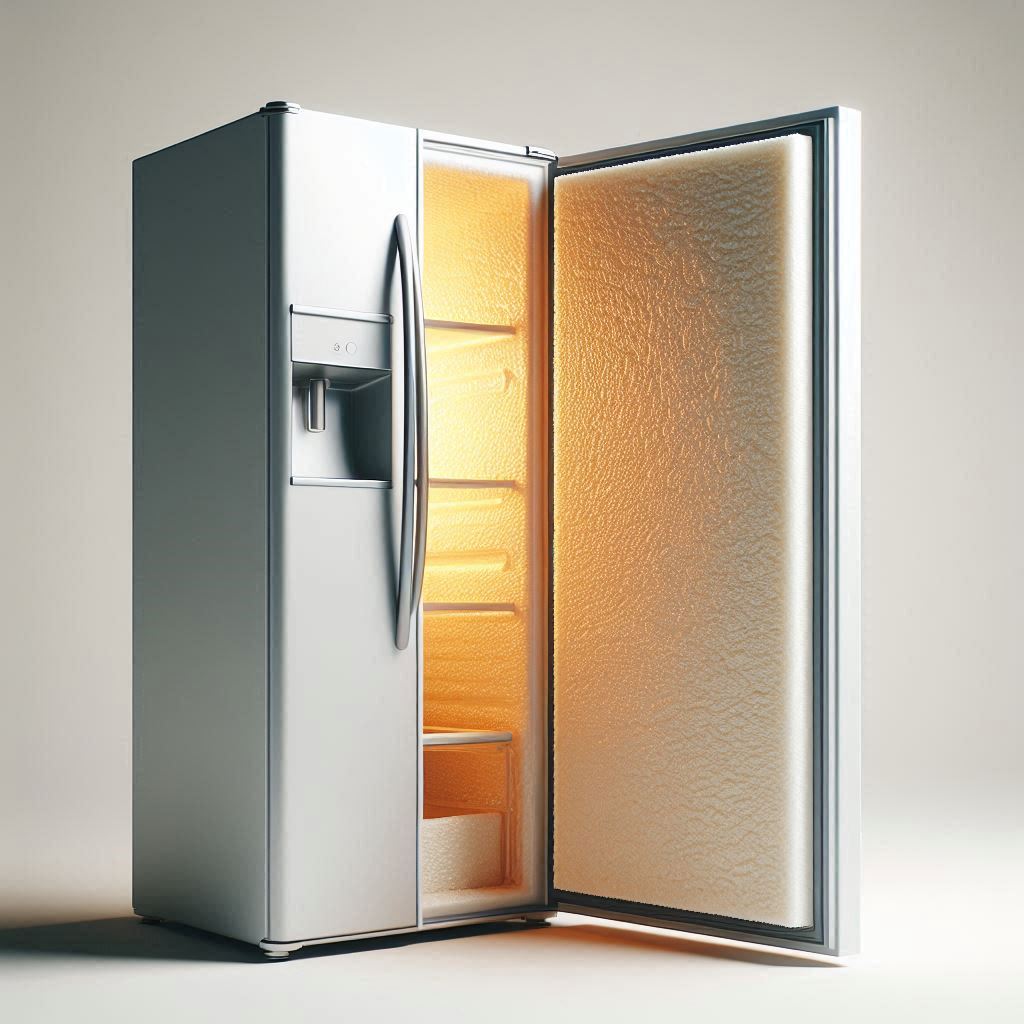

With suitable freezer insulation, keeping temperatures low becomes possible, and also, it affects energy efficiency, operational costs, and long-term reliability. As global energy prices rise and environmental regulations tighten, manufacturers and suppliers are under increasing pressure to adopt insulation solutions that deliver maximum thermal performance with minimal environmental impact.

Among the most commonly used materials in freezer insulation are polyurethane (PU) and polystyrene (PS). Both the polymeric materials have distinct properties that influence their performance, cost, and overall suitability. In this article, we will talk about the differences between these two materials, compare their performance factors, and guide you toward the best choice for long-term efficiency.

Overview of polyurethane and polystyrene as insulation materials

As you may know, polyurethane is a high-performance insulation material created through the chemical reaction of polyols and isocyanates. The material has exceptional thermal resistance, structural integrity, and versatility in manufacturing. Rigid polyurethane foam typically has high closed-cell content and adheres well to refrigerator cabins, making it ideal for seamless insulation in freezers and refrigerated units.

Polystyrene, on the other hand, is a thermoplastic polymer available in expanded (EPS) and extruded (XPS) forms. It is cost-effective and easy to produce, which makes it a popular choice for insulation where there are budget limitations. However, its thermal and mechanical performance is not as good as polyurethane, particularly in demanding commercial and industrial freezer applications. In the following, we will compare them in a more detailed way.

Properties of polyurethane foam for freezer insulation

Polyurethane is often considered as the best material for insulation in cold environments. Its closed-cell structure provides an excellent thermal barrier, significantly reducing heat transfer and improving energy efficiency. This superior insulation capability allows for thinner walls in freezers, maximizing internal storage capacity without minimizing its performance.

Additionally, polyurethane adheres strongly to metal surfaces and other construction materials, creating a uniform insulation layer that eliminates gaps and reduces thermal bridging. This strong adhesion prevents cold air leakage and moisture penetration, two critical factors for keeping the temperatures at consistent low degrees.

Properties of polystyrene foam for freezer insulation

Polystyrene insulation is commonly used for less demanding refrigeration applications due to its lower cost and lighter weight. It is easy to handle, cut, and install, which can help reduce initial labor expenses. EPS and XPS variants provide varying levels of insulation performance, with XPS offering better moisture resistance and thermal properties compared to EPS.

However, polystyrene’s open-cell structure and lower compressive strength make it less durable under heavy loads and freezing conditions. Over time, it may lose insulating efficiency due to moisture absorption, resulting in reduced performance and higher energy consumption.

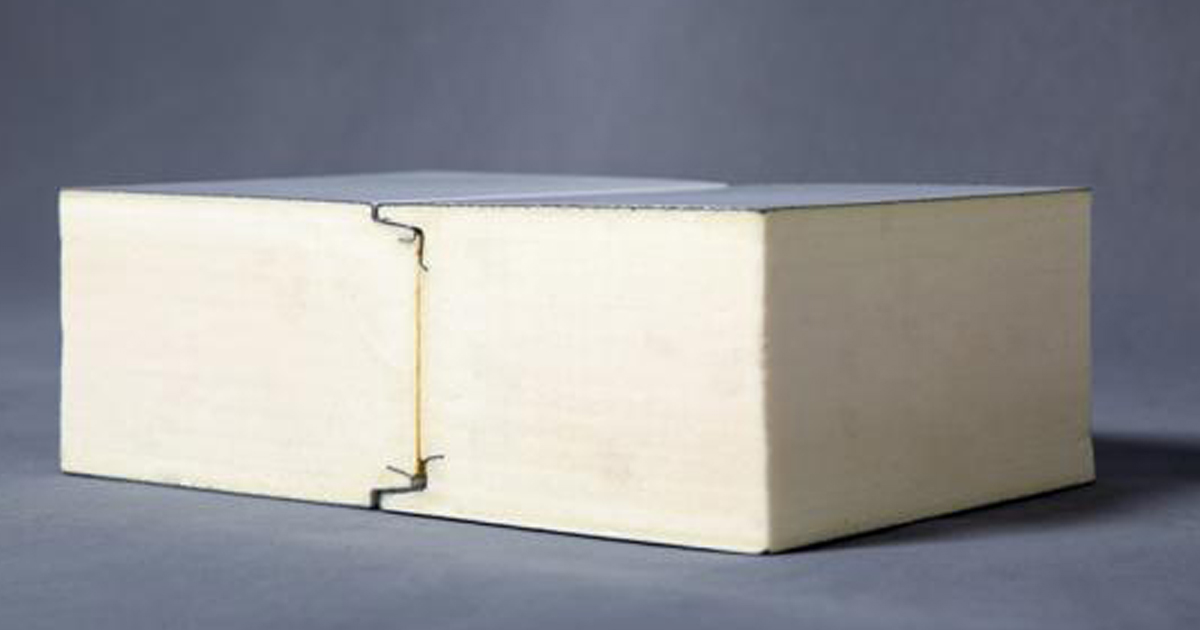

Thermal conductivity of polyurethane foam vs. polystyrene foam

Thermal conductivity is one of the most critical factors in selecting insulation for freezers. The lower the thermal conductivity, the better the material prevents heat transfer. Polyurethane typically has a thermal conductivity rating of 0.020–0.025 W/m·K, making it one of the most efficient insulation materials on the market.

Polystyrene, by contrast, has a thermal conductivity rating of 0.030–0.040 W/m·K. These differences in thermal conductivity mean that for the same insulation value as polyurethane, you require thicker foam while using polystyrene as insulation material. It has to be reminded that thicker foam limits interior space and increases material requirements.

Polyurethane foam vs. polystyrene foam: R-value and insulation efficiency compared

The R-value measures the resistance of an insulation material to heat flow; the higher the R-value, the better the insulation. Polyurethane has a significantly higher R-value per inch compared to polystyrene, which means less material is required to achieve superior thermal performance. This better efficiency means reducing energy costs, particularly for commercial and industrial freezer systems operating under constant low temperatures.

Polystyrene, while adequate for certain low-budget projects, often cannot achieve the same R-value performance without adding significant thickness, which may not be practical for many freezer designs.

Durability and lifespan: Polyurethane vs. polystyrene foam

Freezer insulation must withstand years of temperature cycling, humidity, and physical stress. Rigid polyurethane foam insulation, due to its structure, offers exceptional durability, resistance to compression, and long-term thermal stability. It maintains its insulating properties for decades, ensuring consistent energy performance and minimal degradation over time.

Polystyrene, while has good resistance to some mechanical damage, tends to deform under sustained pressure and freezing, particularly in EPS form. This deformation can create gaps, reduce insulation performance, and lead to increased energy loss over the freezer’s lifespan. In other words, polystyrene foam has inferior mechanical strength to polyurethane foam. This causes its lower durability compared to polyurethane foam.

Preventing moisture and frost: Polyurethane vs. polystyrene foam performance

Moisture penetration is a leading cause of insulation failure in freezer applications. Polyurethane’s closed-cell structure provides excellent moisture resistance, preventing water absorption and frost formation within the insulation. This protects thermal performance and helps avoid the growth of mold and mildew in humid environments.

Polystyrene, especially EPS, is more susceptible to water absorption, which can lead to frost buildup and reduced insulation efficiency. XPS performs better in this regard but still does not have as good moisture resistance as polyurethane foam.

Cost comparison of polyurethane vs. polystyrene foam

Polystyrene is generally less expensive than polyurethane foam, which makes it a budget friendly option. However, in the long-term, better energy savings, reduced maintenance, and extended lifespan, polyurethane proves to be the more cost-effective choice.

In other words, polyurethane may cost more at first, but it reduces heat transfer and helps lower energy bills, making it a smart choice particularly in commercial and industrial applications where freezers operate continuously.

Environmental impact and sustainability of polyurethane vs. polystyrene refrigerator foam

Now a days, sustainability has become a significant factor in insulation material selection. Polyurethane manufacturers are increasingly adopting eco-friendly blowing agents and improving recyclability to reduce environmental impact. In other words, modern formulations often use low-global-warming-potential (low-GWP) or zero-ozone-depleting blowing agents, significantly reducing their environmental footprint compared to older versions.

Additionally, polyurethane’s high energy efficiency helps to lower carbon emissions over the freezer’s operational life (reduced greenhouse gas emissions from energy production).

Recyclability is another growing advantage. Research and industrial practices now allow polyurethane waste to be chemically or mechanically processed into reusable raw materials for new insulation products, minimizing landfill disposal. Furthermore, because polyurethane achieves high R-values with thinner layers, it reduces the volume of raw materials required for insulation, further lowering environmental impact across its lifecycle.

On the other hand, polystyrene, while also recyclable in theory, faces more logistical challenges. EPS and XPS often require complex cleaning and separation processes before recycling, which can be costly and inefficient. Moreover, polystyrene insulation typically requires thicker panels to achieve the same performance level as polyurethane, leading to increased resource consumption and a higher overall environmental footprint.

Polyurethane Products

Which material is better for freezer insulation?

When comparing performance, durability, and long-term cost efficiency, polyurethane clearly performs better than polystyrene in most freezer insulation applications. Its superior thermal properties, high R-value, and excellent moisture resistance make it the preferred choice for high-performance refrigeration systems.

Polystyrene may be suitable for smaller, low-cost projects, but for industries where reliability, energy efficiency, and lifespan are top priorities, polyurethane is the best optimal solution.

Buying polyurethane for refrigerator insulation from Iran

Iran has emerged as a reliable source for high-quality polyurethane raw materials, offering competitive pricing and global export capabilities. Imen Polymer Chemie, a leading polyurethane system house in the region, specializes in supplying premium polyurethane materials designed for demanding insulation applications in freezers, refrigerators, and cold storage facilities.

With a strong commitment to quality, technical support, and international logistics, we ensure that global clients receive superior polyurethane solutions that meet international standards. Whether you are a manufacturer, contractor, or distributor, sourcing from Iran can provide a competitive edge in both performance and quality.

Conclusion

In this article, you find out why polyurethane is the most popular choice for fridge and freezer insulation. It has excellent thermal performance, durability, and long-term value. So, choosing the right insulation material is only part of the equation. To get the full potential of polyurethane and ensure maximum performance in fridge and freezer applications, expert guidance is essential (as you may know, polyurethane is a high-tech material, and you have to have great knowledge to work with it).

Looking for high-quality polyurethane for freezer and refrigerator insulation? Contact Imen Polymer Chemie today and explore our range of advanced polyurethane raw materials designed to enhance energy efficiency, extend equipment lifespan, and reduce operational costs.