Refrigerator insulation

Rigid foam

The most common application of rigid polyurethane foams in household appliances is in the thermal insulation systems of refrigerators and freezers. Rigid polyurethane foam can be a cost-effective material used to prevent energy loss in refrigerators and freezers. The excellent thermal insulation properties of these foams are due to the closed and fine cell structure of the foam and the gases trapped within these cells. Modern refrigerators and freezers include metal sheets on the outer casing and an ABS layer on the inner side. Between these layers, rigid polyurethane foam acts as both a filler and an insulator, applied during the refrigerator’s production, where the foaming and curing process occurs inside the refrigerator body. The adhesive properties of polyurethanes form a strong, stable bond between the inner and outer walls of the refrigerator, also preventing heat exchange between the interior and exterior.

Product codes

Related industries

Some advantages of polyurethane refrigerator insulation foam:

- Good adhesion to the refrigerator cabinet

- Lightweight

- Adequate rigidity and strength

- Excellent thermal insulation

- Resistance to extremely low temperatures

- Water resistance

Imen Polymer Chemie

Some of our latest

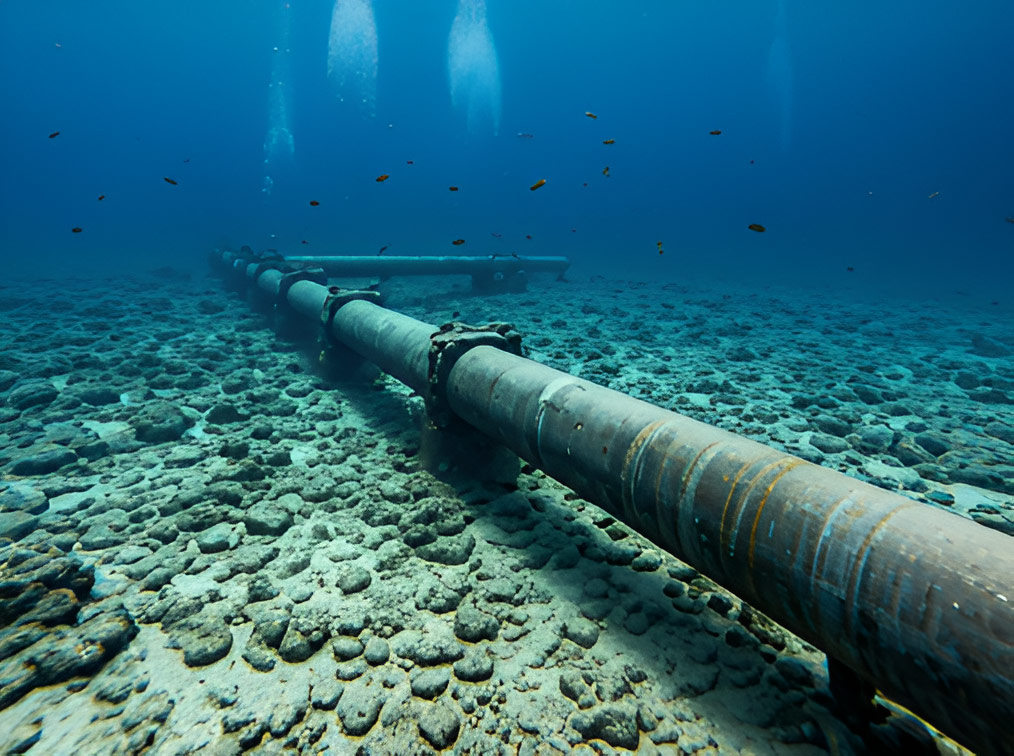

Subsea pipeline insulation

Optimizing electricity consumption in refrigerators with polyurethane insulation

After-sales services

We never leave you

on your own afterwards either

Refrigerator foam

According to estimates by the Food and Agriculture Organization of the United Nations (FAO), about one-third of all food produced for human consumption worldwide (approximately 1.3 billion tons) is lost or wasted each year. On the other hand, the cold transportation chain, which is used for transporting perishable products such as fruits, vegetables, meats, and other goods, relies heavily on proper insulation to help preserve these products at a safe and appropriate temperature for consumption.

Types of refrigerator foams

Various insulation materials are used for refrigeration systems, the most common of which include:

- Polyurethane Foam

- Polystyrene Foam

Comparison of polyurethane insulation foam and polystyrene foam

Polyurethane and polystyrene foams are two types of thermal insulation used in the refrigeration industry. Below are some key comparisons between these two types of insulation:

Polyurethane Foam

Cellular Structure

Polyurethane foam has a closed-cell structure with fine and uniform cell distribution.

Thermal Insulation

Polyurethane foam provides better thermal insulation than polystyrene foam, offering lower thermal conductivity.

Moisture Absorption

Polyurethane foam does not absorb moisture, maintaining its insulating properties over time.

Polystyrene Foam

Thermal Insulation

Although it provides good thermal insulation, its performance is inferior to that of polyurethane foam.

Mechanical Strength

Polystyrene is less resistant to pressure and has a shorter lifespan compared to polyurethane.

The choice between polyurethane and polystyrene foam depends on the specific needs of the project and environmental conditions. For high-performance thermal insulation, polyurethane foam is the better option.

Importance of polyurethane foam in refrigeration industries

More than 800 million people worldwide suffer from hunger, making the production and preservation of food vital. Polyurethane foam plays a crucial role in appliances like refrigerators and freezers used to store food. From household refrigerators to food transport trucks and cold storage warehouses, rigid polyurethane foam helps maintain products at the correct temperature from harvest or production to consumption.

Advantages of polyurethane refrigerator foam

Polyurethane foam withstands physical impacts and other stresses better than polystyrene, providing superior load-bearing and thermal control properties. The mechanical strength of insulation is critical in refrigerator design because the cold components must be supported by the refrigerator cabinet through the insulation. Additionally, due to its long-lasting durability, polyurethane foam is a cost-effective option.

Key features of polyurethane refrigerator foam

Polyurethane foam has the lowest thermal conductivity (0.021-0.025 W/m.K) compared to other available insulation materials, allowing manufacturers to reduce the refrigerator wall thickness. This foam also has lightweight properties, excellent strength, and strong adhesion to various surfaces, including metal and plastic. Its closed-cell structure ensures optimal insulation performance and dimensional stability at low temperatures. This means that the blowing agent used during foam production remains trapped within the cells, improving the foam’s insulating performance. The closed-cell structure also enhances the foam’s strength and prevents moisture from penetrating into the foam.

When injected into the refrigerator body, the foam exhibits good flowability and acts as a structural adhesive, bonding the internal and external refrigerator panels during the foaming process, which facilitates easy application and production.

The performance of polyurethane insulation foam is a key factor in maintaining food at optimal temperatures. This essential property (insulation) depends on the type of blowing agent used during production and its rate of release from the product. In fact, most of the thermal conductivity values, around 65-80%, are determined by the thermal conductivity of the blowing agent or a mixture of blowing agents. Additionally, these blowing agents are gradually replaced by air within the cells over a short period, making it important to assess changes in this parameter over time.

Initially, chlorofluorocarbons (CFCs) were used as blowing agents in the production of polyurethane refrigerator foams. However, due to the environmental issues posed by CFCs and their role in ozone layer depletion, they were later replaced by other blowing agents. After the phase-out of CFCs, hydrochlorofluorocarbons (HCFCs) were widely used in the U.S. and Asia. However, European countries emphasized the use of halogen-free agents, which led to the increased use of hydrocarbons such as cyclopentane, due to its low K-factor (the lowest thermal conductivity among other pentanes). Given the challenges posed by HCFCs, research into alternative blowing agents continues to this day.

Applications of polyurethane refrigerator foam

Polyurethane refrigerator foam can be used in a wide range of refrigeration and cooling insulation applications, including:

- Retail refrigerator insulation

- Household refrigerator insulation

- Industrial refrigerator insulation

- Display case insulation

- Chest freezer insulation

- Upright refrigerator-freezer insulation

- Coleman cooler insulation

- Cold storage insulation

Refrigeration foam purchase

As previously mentioned, the polyurethane raw materials used for refrigerator insulation play a crucial role in both the insulation quality and the overall performance of a refrigerator. The final density of polyurethane foam is controlled by regulating the amount of gas produced within the system. This can be adjusted by the amount of blowing agent used in the system. However, when chemical blowing agents like water are added, urea linkages are formed in the polymer, which can result in a stiffer and more brittle foam. Therefore, the density cannot be altered solely by adding more water or isocyanate without affecting other properties. For this reason, in systems with a single blowing agent, auxiliary blowing agents are used to address these drawbacks and to synthesize foam with relatively low density.

Imen Polymer Chemie Co., a manufacturer of polyurethane raw materials, offers these materials for the insulation of various types of refrigerators as one of its products. The insulation foams produced with these materials have excellent mechanical properties, dimensional stability, good flowability, the ability to uniformly fill refrigerator cabinets, excellent adhesion to the body, and low thermal conductivity. It is also worth noting that these materials, due to their exceptional mechanical properties, can contribute to the structural strength of the refrigerator body.

Summary:

Polyurethane foam helps people around the world access a safe and adequate food supply. One of the main reasons for using polyurethane foam as the most common refrigerator insulation material is its low thermal conductivity compared to other insulating materials.