Table of contents

SRAY-APPLIED POLYURETHANE foam is a unique roofing material. It is sprayed as a liquid directly onto the roofing substrate; within seconds it foams, expanding 20 to 30 times its original volume. The foam forms a fully adhered, closed cell structure that resists water infiltration while providing insulation. Because of these properties, spray-applied polyurethane foam can:

- Improve Drainage: Polyurethane foam can be applied in varying thicknesses to eliminate existing ponded areas and build taper into the roof surface.

- Insulate: The aged R-value of polyurethane foam is about 6.3. Thickness may be built up to achieve a desired value.

- Waterproof Polyurethane foam’s closed cell structure prevents liquid water penetration. Because foam is fully adhered to the substrate, there are no channels for water to flow even if the foam is punctured.

- Breathe: Water vapor diffuses through polyurethane foam. Unusual vapor drive problems can be solved by the appropriate use of polyurethane foam and vapor retarders.

- Self-flash: Separate flashing and counter flashing materials are generally eliminated.

Like all roofing systems, spray-applied polyurethane foam roofs must be properly designed and installed; it’s the purpose of this and subsequent articles to provide clarification and information to the professional roof consultant so that polyurethane foam roofs may be designed, maintained, and repaired intelligently. The remainder of this first article will discuss the basics of polyurethane foam chemistry.

After sales service

For price inquiries and purchasing liquid polyurethane for polyurethane foam production, please contact Imen Polymer Chemie Company.

FOAM CHEMISTRY

Polyurethane foam is the product of chemical reaction: the reaction occurs on the roof surface. Two components, the “resin” and the “iso” are mixed in the nozzle of a spray gun; the mix is spray-applied to the roof surface; the mix reacts, forming a rigid foam.

Basic Ingredients

All polyurethane foam systems manufacturers package their foam chemicals in two container sets (drums, tote tanks, or pressurized tanks). With the exception of some pressurized tank systems, the containers are labeled with the contents and color coded. The containers may come letter coded as follows: A side iso (isocyanate) component; B or R side resin component.

Don’t ever mix the two components without the proper equipment. Equipment used for one component must never be used for the other. The iso and resin will immediately react when mixed; cross contamination will result in a real mess.

Foam chemical systems have shelf lives. The catalyst in the system can age and & “die” Verify that the foam system being applied is within the manufacturer’s stated expiration date.

Foam systems are formulated for use at specified air and surface temperatures. Fast, regular, and slow systems are available for varying seasonal conditions. Always use the manufacturer’s recommended system speed for the specific ambient conditions.

Isocyanate

Polymeric MDI (methylenediphenyl diisocyanate) is an isocyanate that reacts with a polyol resin to form polyurethane. Iso is also highly reactive with water, including ambient humidity.

Handling the iso requires more care than the resin. While in storage and use, iso must be kept clean, dry, and above freezing; otherwise, solids (the polymerized product of the isocyanate-water reaction) may form causing later line blockages and poor quality foam.

Resin

- “resin” is actually a mixture of several components (some are reactant; some are not):

- A polyol is the main reactant ingredient that forms the polyurethane backbone of the foam.

- A blowing agent is a gas generating ingredient (may be reactive) that forms and expands the foam cells as the main reaction proceeds. The amount of blowing agent in the formulation determines the foam density.

- A catalyst is the ingredient that controls the reaction speed of the foam system. A catalyst slowly loses its activity with time; shelf life of foam systems are based on effective catalyst life.

- A surfactant acts as a mixing aid for the components; it helps control cell size.

- A flame retardant reduces the combustibility of polyurethane foam, enabling the foam to meet building code flammability requirements.

While not so sensitive to contamination as iso, the resin mix must also be kept clean and dry. Nonpressurized resin containers may be equipped with a vacuum relief bung. Storage temperatures for resin containers must be controlled (65°F to 85°F). If the resin becomes too hot, evaporation of the blowing agent may cause blowing agent losses and/or over pressure of the container. If it is too cool, the increased resin viscosity will make pumping difficult.

General

Virtually all foam chemical systems are mixed in a 1:1 ratio. Should this ratio not be maintained,”of-ratio” foam is formed. Off-ratio foam (lacking iso or lacking resin) does not meet the physical property requirements of roofing foam; it will blister or leak water or perform in some other undesirable manner.

The iso-polyol reaction generates heat (exotherm). This heat of reaction raises the temperature of the foam ingredients, vaporizing the blowing agent and speeding the reaction. The timing of events during foam formation is critical; the foam chemical systems are precisely formulated to control this timing. Foam chemical systems should never be altered in the field.

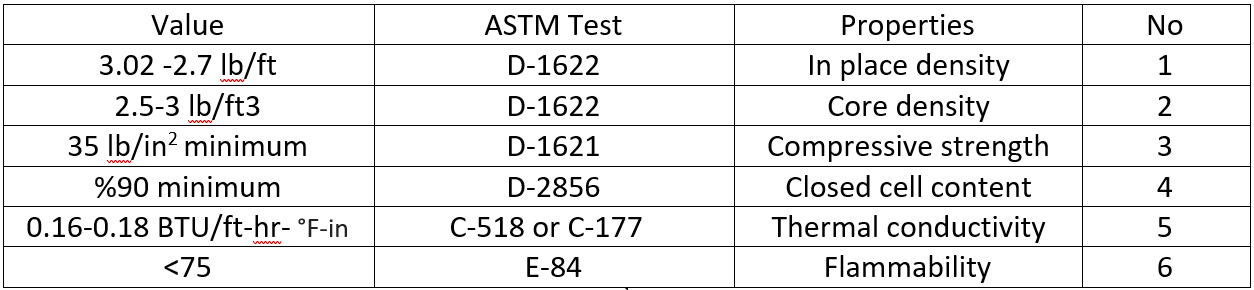

Polyurethane foam is sprayed in passes or lifts to achieve the full specified thickness (usually one inch minimum for coated polyurethane foam systems and 1-1/2 inches minimum for aggregate covered systems). Typical polyurethane foam properties are:

Foam must be applied in pass thicknesses of at least 1/2 inch (cured foam). To apply less thickness risks insufficient mass of material to generate the heat and temperature needed to produce high quality roofing foam and reduce the likelihood of delamination.

Because a reacting foam mass generates heat and because foam is such effective insulation, a large mass of reacting foam can build up a lot of internal heat. Although the surface of the foam mass may only feel warm, the internal temperature can get hot enough to degrade the foam. Roofing foams should not be sprayed too thick at one pass (i.e., build up several passes of foam to the desired thickness). Test spraying (to check foam quality, spray pattern, etc.) should be on cardboard or scrap board. These foam accumulations should be minimized or broken up into smaller pieces a few minutes after spraying to avoid heat buildup and potential spontaneous combustion. Foam thickness per pass: 0.5 inch minimum, 1.5 inches maximum.

Cold substrates can act as heat sinks, absorbing heat from the reacting mass. This loss of heat may result in a loss of foam yield. At worst, the blowing agent may revert to liquid, causing yield loss and substandard foam qualities.

Under typical conditions, foam yields should be 2-1/2 to 3 board feet per pound, depending on foam density (higher density yields less foam).

Reacting polyurethane foam sticks like glue. Atomized droplets from the spray gun may become airborne. The resulting overspray may stick to nearby clothing, eyeglasses, walls, windows, and automobiles. Wear old clothes or disposable garments; do not wear plastic lens eyeglasses; protect camera lenses. The applicator, who is responsible for overspray damage to buildings and cars, should take precautions to avoid this exposure.

Imen Polymer Chemie:Manufacturer and Global Supplier of Liquid Polyurethane

Imen Polymer Chemie is a leading manufacturer of liquid polyurethane in Iran, specializing in the production of high-quality liquid polyurethane products for various industrial applications. With years of experience in the field, the company has established a strong reputation for delivering durable, reliable, and innovative solutions. Imen Polymer Chemie exports its liquid polyurethane products globally, ensuring that customers worldwide benefit from its expertise and cutting-edge technology. The company is committed to meeting international standards, offering a wide range of products for applications such as spray foam, coatings, and adhesives. For inquiries and price quotes on polyurethane for spray foam production, please contact us at 982157325.