Flooring (Floor covering)

Adhesive and coating systems

There are numerous options for flooring, including ceramic, cement, stone, wood, epoxy, and more, suitable for various applications. Among these, polyurethane flooring has gained widespread popularity. These floors offer a smooth, flat surface that prevents the growth of fungi or bacteria and is easy to clean. Additionally, they are highly durable and resistant to abrasion, slip, UV light, chemicals, stains, temperature fluctuations, and impacts.

Characteristics of polyurethane floor coating are:

- High durability

- Abrasion resistance

- Impact resistance

- Chemical resistance

- UV resistance

- Temperature fluctuation resistance

- Easy maintenance

- Customization capability

- Safety in high-traffic environments

- Aesthetic appeal

Related Products

Imen Polymer Chemie

Some of our latest

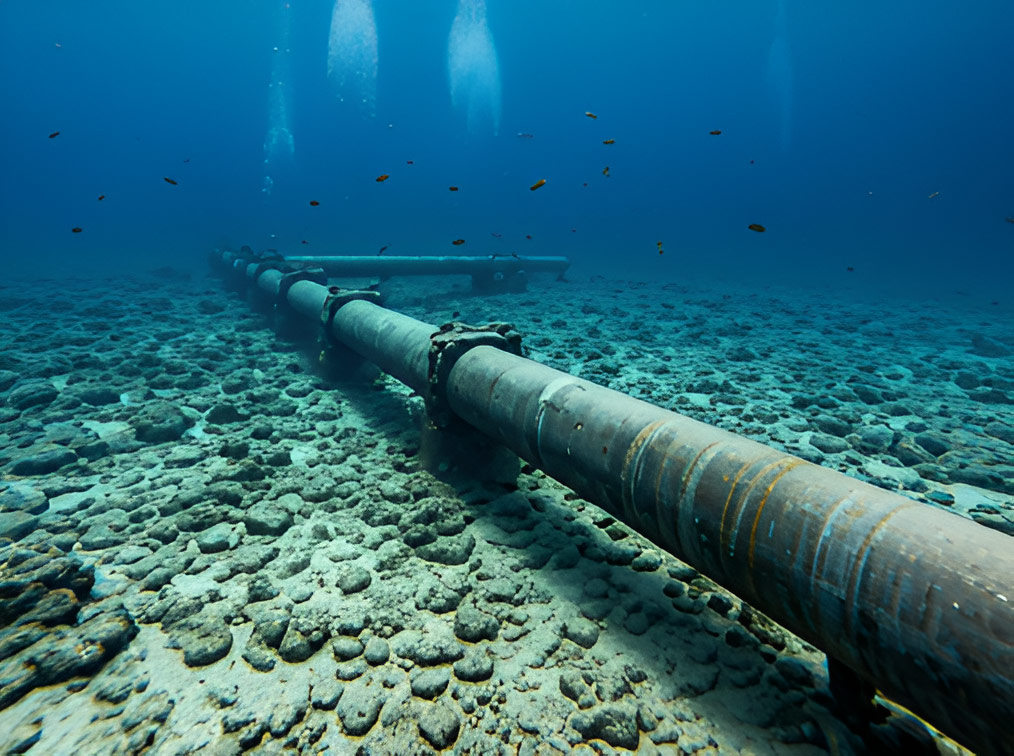

Subsea pipeline insulation

Optimizing electricity consumption in refrigerators with polyurethane insulation

After-sales services

We never leave you

on your own afterwards either

What is Polyurethane Flooring?

Polyurethane flooring, which is also referred to as PU floor coating, is a high-performance, seamless coating system made from polyurethane resins. These floors are known for their exceptional resistance to chemicals, abrasion, and mechanical stress, making them ideal for demanding environments. Unlike traditional flooring materials that may crack or wear over time, polyurethane foam flooring keeps its integrity in tough conditions. In fact, they are durable and do not damage easily.

PU flooring is applied as a liquid polymeric material that cures and gets harder, making a tough or rigid surface (based on the formulation). It has an elasticity that allows it to withstand minor movements without cracking, making it highly suitable for industrial, commercial, and even residential applications.

In this article we will discuss its advantages and disadvantages, characteristics, applications and limitations. Also, we will guide you through buying and installing the material.

PU flooring advantages and disadvantages

Polyurethane floorings have several benefits that sets them apart from other flooring materials. The advantages of PU flooring are as follows:

- They are flexible and elastic so they do not crack easily, absorb impact and vibration and can tolerate small ground movements.

- They have great resistance to wear and abrasion and also, to chemicals, thermal shock; that’s why they are called durable.

- They make spaces safer and cleaner; due to their smooth, anti-static properties, and slip resistance characteristics. They can provide seamless flooring that is resistant to bacterial and fungal growth.

- They can be simply applied and quickly cured. This is advantageous for projects with short times.

- They have excellent UV radiation resistance and keep their fine look or aesthetic finish.

Despite all the above-mentioned superiorities, they have some drawbacks; the disadvantages of PU flooring include:

- They are susceptible to humidity; in other words, they should be applied on a surface that is as dry as possible.

- For applying multiple layers, you have to wait until each layer cures completely.

- They are somehow more expensive than traditional flooring systems (due to their superior properties), but the long-term durability worth the higher cost.

Also, it has to mentioned that the advantages depend highly on proper surface preparation and professional installation (mistakes during application can affect performance).

Characteristics of polyurethane flooring

One of the outstanding characteristics of polyurethane flooring is its flexibility that we mentioned just before. This property enables the floor to absorb shocks and adapt to structural movements, reducing the possibility of cracks formation over time. It is also resistant to temperature fluctuations, which is especially important in environments like cold rooms or outdoor settings where expansion and contraction cycles are common.

Another key feature is its chemical resistance. PU flooring resists a wide range of acids, alkalis, solvents, and cleaning agents. This makes it an excellent choice for industries that deal with corrosive substances/detergents. Additionally, the surface of polyurethane flooring is often designed to be anti-slip and reflective, improving safety and reducing lighting costs. These characteristics cause its long-term durability and reduced maintenance expenses.

Applications of polyurethane flooring

Due to various characteristics of polyurethane flooring, it can be used in wide range of applications in different industries, including:

Industrial

Ideal for heavy-duty use in factories, warehouses, manufacturing plants, and distribution centers. Its resistance to impact, abrasion, and chemicals ensures long-term performance in industrial facilities.

Commercial

Commonly used in retail stores, restaurants, offices, and showrooms where both durability and appearance of flooring are important. PU flooring can tolerate high traffic areas and come in a variety of finishes to match interior designs.

Healthcare

Suitable for hospitals, clinics, and laboratories due to its seamless, easy-to-clean surface (places that needs to follow strict hygiene standards and regular sanitation processes). In other words, the seamless nature of PU flooring prevents the buildup of bacteria and dirt, ensuring hygiene regulations are obeyed carefully.

Educational

Applied in schools, universities, and sports facilities where safety, slip resistance, and long-term durability are key considerations.

Residential

A practical flooring option for areas such as kitchens, basements, and garages, offering a clean, waterproof surface with excellent resistance to stains and wear. Also, it is available in a variety of textures, and colors, that allows customization according to the design and functionality of the space.

Other applications

Widely used in car parks, sports halls, and other high-traffic areas where great performance and long-term maintenance efficiency are that necessary.

Limitations of using polyurethane flooring

Despite all the benefits of PU flooring, it has some limitations such as the following:

Moisture sensitivity

Polyurethane floors are sensitive to moisture during installation and humidity in the environment can also cause curing issues. In simpler terms, wet substrates can cause bubbles in the flooring and surface defects may appear.

Curing process

Polyurethane flooring needs time to cure fully. Cold temperatures can delay or prevent the curing process. Fast curing also happens in warm weathering conditions. Generally speaking, the curing process is temperature-sensitive and below some temperatures curing will not happen at all.

Installation and application

This flooring needs professional installation. Improper surface preparation, or incorrect mixing ratios during application can lead to bubbling, peeling, or uneven curing.

Suitable thickness of polyurethane flooring

The appropriate thickness of polyurethane flooring depends on the specific application and load requirements. In areas with low traffic, such as laboratories or residential spaces, a thin coating of 2–3 mm may be enough. This thickness generally provides the necessary protection against wear and chemicals without unnecessary cost or material use.

For busy and high traffic applications, such as in manufacturing plants or cold storage warehouses, higher thicknesses about 4–6 mm are suggested. In areas exposed to extreme thermal shock or chemical exposure, even thicker coatings (sometimes up to 9 mm) may be necessary.

Overall, remember that selecting the right thickness ensures optimal performance, longevity, and cost-efficiency of the flooring. This makes expert consultation an important part of the process.

How to install polyurethane flooring?

First of all, it has to be mentioned that installing polyurethane flooring is a multi-step process that should be performed with great precision and by experienced installers. Commonly, you have to go through the following procedure to ensure a proper and long-lasting installation:

Step 1: Surface preparation

- Clean the substrate surface thoroughly to remove dust, grease, oil, and even old coatings.

- Repair any cracks, holes, or damaged areas using appropriate fillers.

- Use grinding or shot blasting to roughen the surface and improve adhesion.

- Ensure the surface is completely dry to avoid bobble formation in the flooring.

Step 2: Priming the substrate

- Apply a suitable polyurethane-compatible primer to seal the surface and enhance bonding/adhesion. The proper priming process prevent occurrence of outgassing.

- Allow the primer to cure as recommended by the manufacturer (typically a few hours).

Step 3: Mixing the polyurethane

- Accurately measure and mix the polyurethane components according to technical datasheets.

- Proper mixing of the components is of great importance (this directly affects the final performance of the flooring).

- To prevent waste or early curing, only prepare and mix as much material as you can apply within the working time.

Step 4: Applying the coating

- Pour the polyurethane mixture on the surface and use squeegee or roller to spread and level the coating.

- To reach the required thickness, multiple layers can be applied, but before applying the next one, make sure that the flooring has been cured completely.

- Add a topcoat if chemical resistance, UV stability, or color retention is required. That is to say, for enhanced durability a topcoat is applied in industrial settings where chemicals and abrasion are common.

- Decorative textures or patterns can also be applied at this stage.

Step 5: Curing

- Allow the floor to cure in a controlled environment, usually between 24–72 hours depending on temperature and humidity.

- Prevent foot or equipment traffic until full curing is complete. Normally, spike rollers and spike shoes are used to achieve this purpose.

Step 6: Final inspection and handover

- Check the surface for uniformity, gloss, and thickness.

- Ensure there are no bubbles, pinholes, or missed areas.

- Clean the surface and prepare it for use.

Buy polyurethane flooring raw materials from a trusted Iranian manufacturer

Imen Polymer Chemie is a leading manufacturer and system house of polyurethane raw materials in Iran, offering professional and specialized solutions for polyurethane flooring formulations. With a strong foundation in technical knowledge, a fully equipped R&D laboratory, and an experienced technical support team, our company delivers high-quality, consistent, and performance-driven materials to a wide range of industries.

What sets us apart is our ability to offer custom formulations tailored to specific project requirements. Our company provides full technical consultation before and after purchase, ensuring smooth implementation and optimal performance. With the help of deep understanding of industrial challenges and application conditions, we formulate reliable polyurethane systems that deliver long-term durability and efficiency. If you’re looking for a trusted, experienced, and innovative partner in polyurethane raw materials for flooring, Imen Polymer Chemie is the smart choice.

Conclusion

Polyurethane flooring represents a modern, versatile, and highly durable solution for a wide range of applications from hygienic food facilities to commercial or even residential areas. With advantages like chemical resistance, flexibility, and seamless application, it has proven to be a reliable choice for demanding environments. However, choosing the right formulation type from reliable suppliers and proper installation are other factors you better to consider.

Choosing polyurethane raw materials from Imen Polymer Chemie ensures that your flooring systems are built on a foundation of quality, innovation, and tailored support. Whether you are an industrial project manager, a flooring contractor, or a distributor of PU materials, partnering with Imen Polymer Chemie guarantees performance, consistency, and peace of mind. Ready to take your flooring systems to the next level? Contact us today.

What sets us apart is our ability to offer custom formulations tailored to specific project requirements. Our company provides full technical consultation before and after purchase, ensuring smooth implementation and optimal performance. With the help of deep understanding of industrial challenges and application conditions, we formulate reliable polyurethane systems that deliver long-term durability and efficiency. If you’re looking for a trusted, experienced, and innovative partner in polyurethane raw materials for flooring, Imen Polymer Chemie is the smart choice.