Polyurethane shoe soles

Elastofoam

The advent of polyurethane soles revolutionized the footwear industry, and today, most shoes are made using this material. Polyurethane can be used in the inner, middle, and outer layers of shoes, depending on the need and application. It is a popular choice among footwear designers due to its good flexibility at low temperatures, resistance to wear and tear, and the ability to be produced in various densities depending on the level of porosity required. Additionally, when polyurethane is used in the outer soles of shoes, polyester polyols are often employed in their production, as they provide better abrasion resistance than polyether-based materials.

Imen Polymer Chemie

Some of our latest

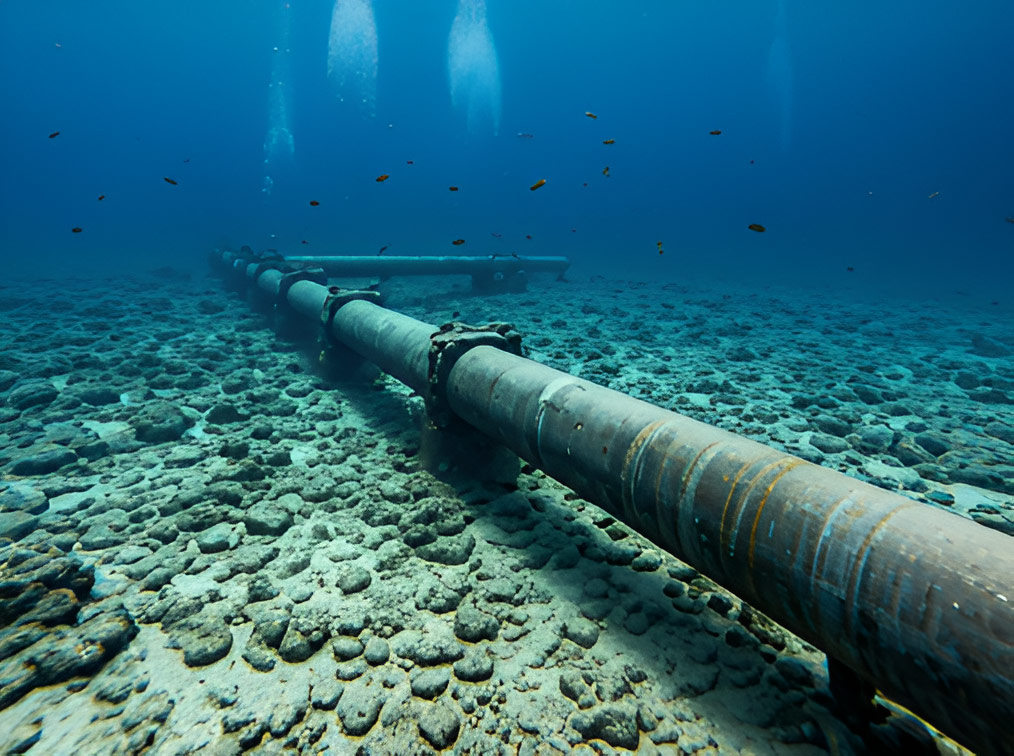

Subsea pipeline insulation

Optimizing electricity consumption in refrigerators with polyurethane insulation

After-sales services

We never leave you

on your own afterwards either

polyurethane soles for shoes

Footwear plays an important role in our daily lives, in better words, it can provide us comfort, support, and protection. Among the main components of a shoe, the sole is the major part, it influences the performance, durability, and convenience.

There are different types of materials that can be used as shoe soles; one of the most common ones is polyurethane (PU). PU shoe soles have a history dating back to the 1960s, since then they become a popular choice for manufacturers due to their desirable properties like lightness, abrasion resistance, and so on. In this article, we will talk about PU soles and compare different types of them, we will also help you choose the right shoe sole, at the end, we will introduce you a famous PU sole raw material manufacturer.

What are polyurethane (PU) shoe soles?

Polyurethane (PU) is a polymer produced by the reaction of a polyol (an alcohol with more than one hydroxyl group) with a diisocyanate, in the presence of various additives and catalysts.

Shoe soles made of PU shows exceptional performance characteristics and that’s why it has become so popular among people. Also, PU can be formulated in almost a wide range of densities and hardnesses, making it an ideal material for shoe soles.

In footwear applications, PU is generally used as a two-component system that reacts to form the sole. One component is typically a polyol blend, and the other is an isocyanate. When these materials are mixed, a rapid polymerization and foaming reaction occurs, and the mixture expands to fill a mold and form the desired sole shape.

It has to be mentioned that for shoe soles, thermoset PU foams (rather than thermoplastic polyurethane (TPU)) are most common due to their better performance characteristics and dimensional stability.

Why is polyurethane the best material for shoe sole production?

PU has various advantages that sets it apart from many other materials. In the following, we will mention the main ones.

Durability:

PU soles are known for their high abrasion resistance, which leads to longer life even in rough usage conditions. In other words, the chemical structure of PU provides a strong, resilient matrix that can resist degradation caused by common environmental factors (some other materials may crack over time).

Lightweight

Despite their strength, PU soles are lighter than rubber or PVC alternatives. This property is really useful especially for athletic footwear where every gram matters and for work boots where heavy soles can lead to fatigue (lightness is a sign of comfort).

Flexibility:

PU offers excellent elasticity and flexibility, which makes shoes more comfortable and adaptable to foot movement. In fact, PU soles can be formulated in a way that have varying degrees of flexibility, and this flexibility promotes natural foot movement. This reduces the possibility of foot strain.

Shock Absorption:

The material’s cellular structure allows it to absorb energy effectively and reduces the impact on joints during walking or running. It means that the structure of PU foam can be compressed, and it will rebound efficiently, dissipating energy from ground strikes. This property is important for reducing stress on feet muscles, and preventing fatigue, especially in activities that you have to stand for long period of time like walking or running.

Slip Resistance:

PU soles have great grip and traction on various surfaces. It has to be stated that while other materials like rubber offer excellent grip and durability, and EVA provides lightweight cushioning, polyurethane is the most popular material for sole production, because it has blend of all these desirable characteristics.

Chemical Resistance:

PU soles are generally resistant to most chemicals like oils, greases, and so on. This makes them to be favorable for industrial footwear. Also, this resistance leads to the longevity and safety of the footwear in tough environments.

Comparison of different types of polyurethane shoe soles

The term “polyurethane shoe soles” refers to wide range of formulations and structures, and each of them can be tailored to specific performance requirements. In the following we will talk about the most common ones.

1. Single-density PU soles

These soles are commonly made from polyester polyols and have high mechanical strength and abrasion resistance. They are firmer and more wear-resistant than polyether-based PU soles, but more sensitive to hydrolysis (degradation in moisture). In better words, polyester-based PU soles are cheaper and more available at the market; they are great especially for industrial and safety footwear. On the other hand, polyether ones are used selectively, mainly for high-humidity or specialty applications.

Single-density PU soles are commonly found in casual footwear, some athletic shoes, and general-purpose work boots.

2. Dual-density (or multi-density) PU soles

These soles made from two (or more) layers of polyurethane materials with different densities, that each of them plays a specific role. The outsole is made from higher density PU so, it is tougher and more abrasion resistant. While the midsole is softer and made from lower density polyurethane. The midsole is lightweight and can absorb shocks. This combination shows a balance of comfort (lightness), durability and performance (better slip, grip and abrasion resistant).

The dual density soles are mostly used for athletic shoes, safety footwear, and hiking boots where careful control over cushioning and support is of great importance.

3. Thermoplastic polyurethane (TPU) soles

Although most PU shoe soles are thermoset materials, Thermoplastic Polyurethane (TPU) is a special type of polyurethane that are also common. This polymer (TPU) is processed like plastic. It has great flexibility, strength, and aesthetics at the same time, with excellent abrasion resistance and transparency. It is denser and less foamed than traditional PU, often used for outsoles or specific structural components within the sole.

TPU soles are frequently used as external shoe elements like heel counters, or entire outsoles in athletic and fashion footwear.

4. Recycled or eco-friendly PU soles

These soles are newer innovations that are made with partially or entirely from reprocessed PU material. The soles were invented with the aim to reduce environmental impact and promote sustainability. In another words, recycled PU soles are normally produced by collecting waste (trimming scraps) from shoe production or post-consumer waste from used shoes. Common applications of recycled PU soles are casual and fashion footwear.

The choice among these types of PU soles depends on the intended use of the footwear, the desired balance of comfort, durability, weight, and cost, and any specific environmental or safety requirements.

Key tips for choosing the right shoe sole

Selecting the right shoe sole is important for comfort and also for foot health, durability, and performance in various environments. One of the major tips is to consider the functionality of the footwear. Meaning that where do you want to wear the shoes? Is it for sports, daily use, work, or medical support? As we mentioned just before, e.g., athletic shoes need soles that provide good shock absorption and grip, while work boots need soles resistant to oil, abrasion, and slipping. Don’t forget that the sole’s design and the intended use should match.

Another fundamental factor is the material of the sole. Each material has its own advantages and disadvantages. Polyurethane soles have unique properties that makes them ideal for both casual and performance footwear. Other materials can be also commonly used for shoe soles production. So, understanding the characteristics of each material helps users make informed decisions based on their needs.

In the end, consider the ergonomics and foot support. A good shoe sole should promote natural foot movement and provide enough arch and heel support. When testing shoes, pay attention to how the sole bends, how much cushioning it provides, and whether it supports your foot’s anatomy. Also, don’t overlook the weight and thickness of the sole (thicker soles isn’t always better), especially if flexibility is required. A properly chosen sole can really affect your feeling of comfort in daily life.

Purchasing shoe sole materials from Imen Polymer Chemie

If you are a footwear manufacturer or in the business of producing shoe insoles and soles, buying high-quality raw materials is crucial to achieving durable, comfortable, and market-competitive products. Imen Polymer Chemie is a trusted supplier of polyurethane raw materials tailored specifically for shoe sole applications. With years of expertise in polyurethane systems, we provide customizable formulations that meet the technical and aesthetic needs of various footwear types, from lightweight sports shoes to orthopedic and industrial safety shoes. Moreover, our shoe sole raw materials are two component systems that are liquid at the environment temperature (they don’t need oven).

Also, by choosing us you will receive technical consultation on selecting or customizing formulations based on your production method. For more information or to place your order, you can contact our sales team or visit our website.

Conclusion

Polyurethane shoe soles have revolutionized the footwear industry due to their offering properties such as lightweight nature, excellent shock absorption, and long-lasting resilience. They can provide shoes a great balance of comfort, durability, and performance. Also, their adaptability to different densities and applications makes them a preferred choice among manufacturers.

For producers looking for consistent quality, custom formulations, and expert support, sourcing polyurethane raw materials from a trusted supplier is key. Imen Polymer Chemie is proud to offer high-performance PU systems specifically tailored for shoe sole production helping manufacturers achieve exceptional results with every step.