Table of contents

Due to the fact that energy resources are limited and the price of energy consumption is high, one of the most important principles that must be considered during building construction is the issue of optimizing energy consumption by changing the consumption pattern.

It can be said that energy efficiency or energy saving is a solution to mitigate the climate crisis. In fact, a huge part of energy consumption in the country is in the building sector. Therefore, the desire and need for buildings that are more efficient in terms of energy consumption has focused on the use of polyurethane systems and products, which we will discuss in the following article.

Importance of energy efficiency in buildings

Energy efficiency and recycling continue to be an important issue facing both industry and the consumer.

Energy lost through walls, roofs and windows is the largest single waste of energy in most buildings. Energy loss in buildings means extra operating costs, loss of comfort, and reduced productivity. Therefore, optimizing energy consumption by providing adequate comfort and reducing environmental impact is essential to achieve cities with cleaner air, thus contributing to the achievement of the Sustainable Development Goals (SDA).

When it comes to energy efficiency in buildings, plastic-based products such as rigid polyurethane foam (PUR), spray polyurethane foam, and polyisocyanurate foam insulation (PIR or polyiso) are at the center of the discussion because they are some of the most efficient thermal insulating products for buildings.

Polyurethane foam for thermal insulation

Polyurethane foam’s structure ensures a low thermal conductivity thanks to which the thermal insulation values required are reached with a minimum of thickness. Compared to other materials, the thermal insulation provided by polyurethane is 700% better than the one provided by bricks and 50% better than the one provided by glass wool.

In all thermal insulation system, whether it is polyurethane or other material, a proper installation is key, so that the final result reaches the desired thermal performance. If the installation of the thermal insulation is not executed properly, problems such as air infiltrations, voids or dirt might appear, which would prevent the insulation assembly from offering a good performance.

After sales service

For price inquiries and purchasing liquid polyurethane for polyurethane foam production, please contact Imen Polymer Chemie Company.

High insulation performance

Polyurethane foam is a thermosetting insulation, providing structural performance and fire resistance. Polyurethane products have a strong yet lightweight structure, are dimensionally stable, moisture resistant and durable. This combination of properties allows manufacturers to design polyurethane thermal insulating products for many diverse applications. Also, they can perform as external air barriers, helping prevent the infiltration of outside air and the escape of indoor air.

This high-performance combination is unique, encompasses a wide range of manufacturing processes, and results in thermal insulation products with multiple functions. For example, spray polyurethane foam (SPF) insulation products can be spray applied to various substrates and others can be molded to special shapes in relatively large sizes. High-density SPF has a high mechanical strength that can add rigidity to lightweight walls or roof decks.

Structural Insulating Panels are pre-manufactured in a variety of sizes, allowing for quick on-site assembly into a building using a minimum number of workers.

Measuring thermal insulation performance

Although several values are used to measure different aspects of the thermal performance of materials, such as C-value (thermal conductance) and K-value (heat transfer between the outside and inside of a building), the insulation performance of a product is typically measured using three thermal values: the coefficient of thermal conductivity (λ), thermal resistance (R) and thermal transmittance (U).

Insulation performance is typically measured by R-value, or thermal resistance. The higher the R-value, the better the material insulates against heat transfer. PUR and PIR foams have some of the highest R-values per inch of all commercially available insulation products. This allows for energy efficient designs featuring thin walls and low-profile roofs; consequently, the architect or engineer can maximize the usable space in a building while reducing operating costs.

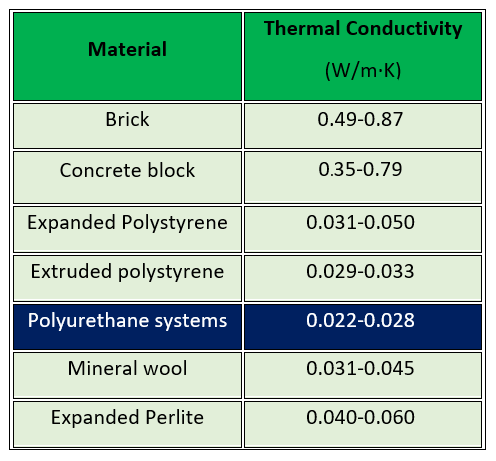

When insulating a building it is important to know the thermal conductivity of the materials used since its energy efficiency and thermal comfort will depend on it. In other words, to improve the energy efficiency of buildings, one of the physical properties that will determine whether a material is a good thermal insulation or not, is thermal conductivity. Thermal conductivity of different common building insulations is illustrated below:

Finally, you get that the main reason for popularity of polyurethane systems in the building sector is their excellent performance as thermal insulation that provides energy efficiency and interior comfort of buildings.

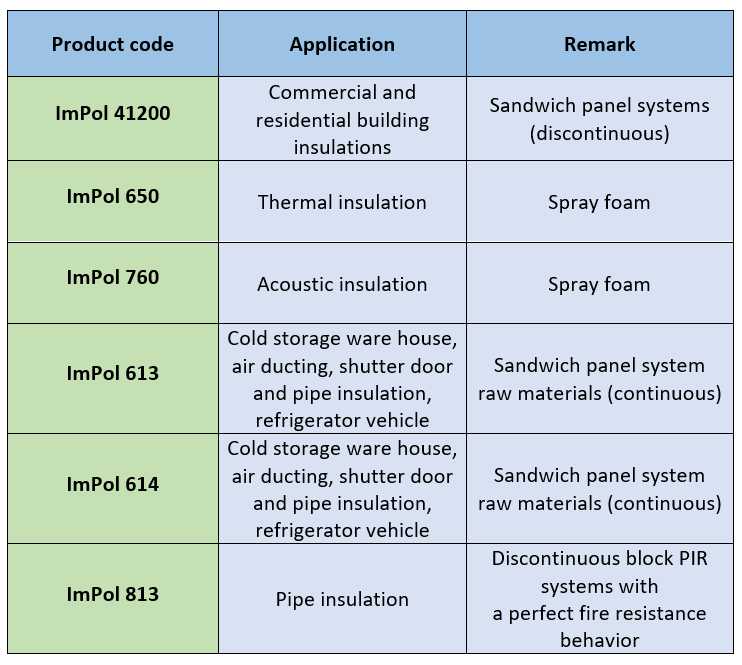

Knowledge based Imen Polymer Chemie Company has designed various polyurethane materials in order to improve energy consumption in buildings; These products are supplied with the following codes:

For more detailed information, be in touch with us.