Foam in place packaging (Packaging Foam)

Specialty products

This type of foam is a custom packaging solution; when the materials are mixed and injected into special bags, the foam forms around the item inside the package in seconds. This product can effectively shape and conform around objects, making it ideal for securing and packaging items. The resulting foam acts as a shock absorber due to its high impact resistance, protecting the packaged item from potential damage. It is an ideal choice for packaging fragile, sensitive, and complex-shaped items, including valuable or sharp-edged goods.

Some advantages of polyurethane in situ packaging foam (foam in place packaging):

- Simplicity (easy usage)

- Customizable (versatile packaging based on application)

- Cost-effective

- Lightweight (reducing transportation costs)

- Effective for odd shape or heavy items with sharp edges

- Ideal for packaging with limited storage space

- Protects products against sudden impacts

Imen Polymer Chemie

Some of our latest

Spray polyurethane foam roofing

Roof sandwich panels and their different types

After-sales services

We never leave you

on your own afterwards either

Polyurethane packaging foam

Protecting products during transportation and storage is a critical concern for manufacturers and distributors especially in an increasingly demanding and competitive global supply chain.

No matter it’s a sensitive electronic device, a medical instrument, or an antique item that needs a reliable protection, the packaging material must keep the product safe and easy to handle. This is where polyurethane packaging foam becomes so popular. As a flexible, resilient, and customizable material, polyurethane foam performs batter than traditional packaging options in nearly every aspect.

In this article, the unique characteristics, advantages, and applications of polyurethane (PU) packaging foam and why it’s become a preferred choice in protective packaging worldwide are discussed.

What is polyurethane packaging foam?

Polyurethane packaging foam is a lightweight, soft, and durable material that can be created by the chemical reaction of polyols, isocyanates and necessary additives. Depending on the formulation, PU foam can be designed with open-cell or closed-cell structures, each offering distinct performance features. In the packaging industry, open-cell polyurethane foam is widely used for its excellent shock absorption, energy dissipation, and the ability to mold exactly to a product’s shape.

Unlike rigid packaging solutions, PU foam can conform to the shape of the product it protects, reducing movement during shipping and lowering the risk of impact damage.

It’s ideal for fragile, unique and/or odd shaped items such as electronics, glassware, laboratory tools, industrial components, and precision instruments. Concerning its versatility, polyurethane foam can be engineered in various densities, firmness levels, and formats, and this makes it an essential solution for businesses that prioritize both product safety and efficient logistics.

Top 6 benefits of PU foam in packaging

Polyurethane foam packaging has various advantages, including:

1. Outstanding impact protection

This polyurethane foam is formulated in a way to absorb and disperse shock, vibration, and mechanical stress during transportation. It reduces the chances of product damage, breakage, or malfunction, particularly for delicate or sensitive items.

2. Lightweight for cost-efficient shipping

Despite its cushioning abilities, PU foam is remarkably lightweight. This helps reduce overall package weight, contributing to lower shipping costs and improved fuel efficiency in logistics.

3. Custom fit and design flexibility

This special PU foam can contour the specific product’s geometry, offering a custom packaging. This customizability enhances product presentation and maximizes protection (the product cannot move in the packaging).

4. Thermal resistance and insulation

Certain grades of PU foam offer thermal insulation, which can help protect products that are sensitive to temperature fluctuations during storage or delivery such as pharmaceuticals.

5. Mechanical durability and stability

The foam has great mechanical strength and do not easily deform under physical pressure. This makes it suitable for packaging heavy and impact-sensitive goods.

6. Clean and non-abrasive

Polyurethane foam doesn’t create dust or loose fibers like some other materials do. It’s soft and gentle, so it won’t scratch or damage delicate items. This makes it a great choice for protecting valuable things like electronics, glass, or lenses during shipping and storage.

Types of polyurethane foam packaging

Polyurethane foam can be manufactured and applied in different formats depending on the specific packaging needs. Generally, PU foam packaging falls into three main categories: molded foams, foam-in-place packaging systems and block foams; below, they are discussed in detail.

1. Molded polyurethane foam

Molded PU foam is produced using pre-designed molds that generally follow the general shape and dimensions of the product. While it offers a consistent and professional appearance, it doesn’t fully conform to every surface detail of the item. Molded foam is best suited for products with predictable shapes and consistent sizes, such as tools, instruments, or retail sets.

Key features:

- Good dimensional matching for standardized products

- Provides a clean, structured look for presentation

- Ideal for batch production of similar items

- High repeatability for large-scale production

- Great mechanical strength and durability

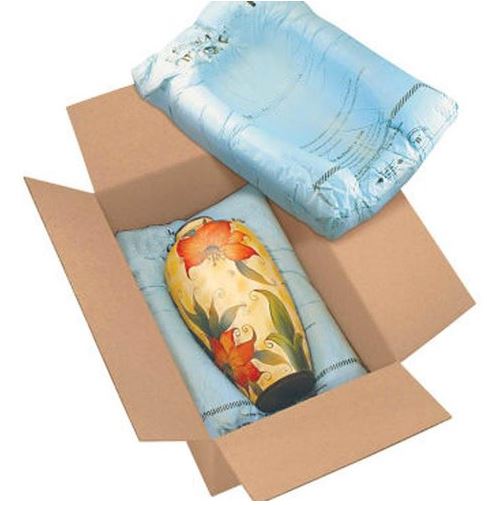

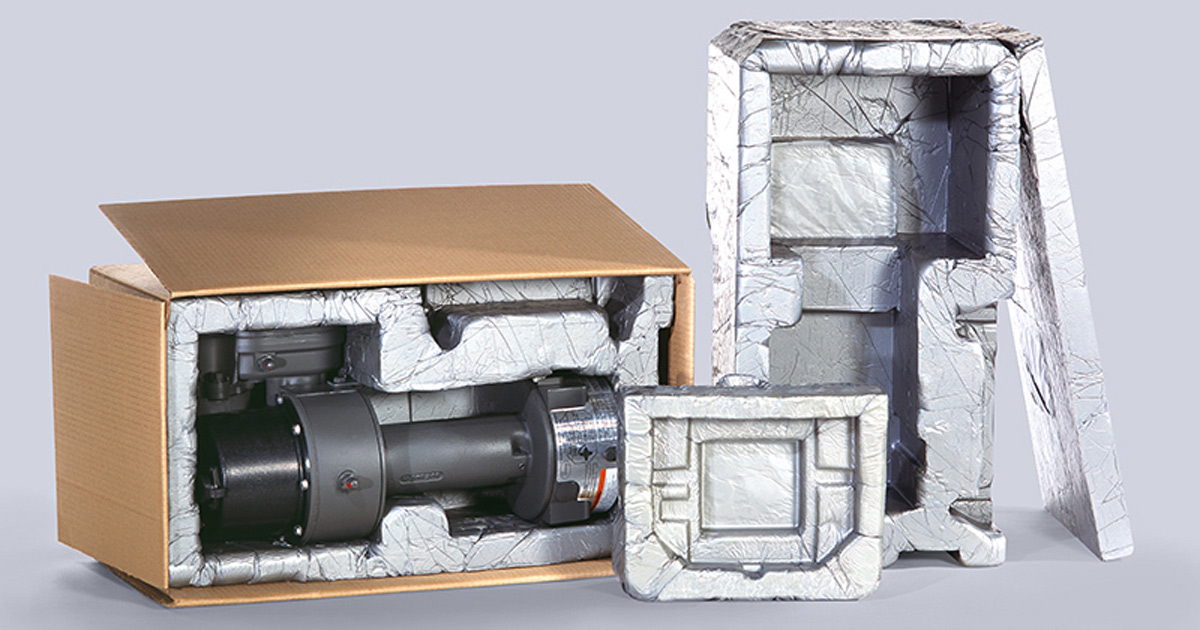

2. Foam-in-place polyurethane foam

In this method, the foam components are mixed and poured directly into the package around the item. The foam then expands and cures in place, forming a perfectly contoured cushion around the product. This is especially useful for shipping fragile, oddly shaped or even heavy items in low to medium volumes.

Key features:

- Fully conforms to the product’s exact shape

- Ideal for low-batch or one-off shipments

- Fast application with minimal tooling

- Provides superior cushioning for sensitive goods

3. Block polyurethane foam

Block foam is produced in large foam blocks or sheets, which can then be cut, die-cut, or CNC-machined to desired sizes and shapes. This format is highly versatile and allows packaging manufacturers to produce inserts, pads, or liners tailored to their specific needs without the requirement for molds.

Key features:

- Flexible cutting to custom dimensions

- Cost-effective for a wide range of products

- Available in various densities and firmness levels

- Ideal for general-purpose protective packaging

So, whether through molded precision, foam-in-place adaptability, or block foam flexibility, each type delivers unique benefits based on product shape, volume, and handling requirements. Choosing the right format ensures both effective protection and cost-efficient packaging performance.

PU foam vs. traditional packaging materials: Which one offers better protection and cost efficiency?

Many industries still rely on conventional packaging options such as expanded polystyrene (EPS), or bubble wrap. While these materials offer basic protection, they often fall short in key areas, especially for fragile or high-value goods.

Polystyrene, for example, can crack under stress, lacks flexibility, and may generate static electricity which is a concern for electronic items. Bubble wrap is lightweight but offers insufficient performance, especially for high-value goods over longer shipping durations. In contrast, polyurethane packaging foam provides:

- Better cushioning performance under both static and dynamic loads

- Resistance to tearing, crumbling, or deformation

- Custom shaping for irregular or complex product designs

- A wide range of densities and hardness levels to match product requirements

- Better surface protection and abrasion resistance

PU foam’s consistent performance, durability, and adaptability make it a more reliable and advanced choice for modern packaging demands.

Uses of PU foam in packaging

PU foam is widely used in packaging industry due to its extraordinary properties. Some of its common applications are mentioned as follows.

Electronics packaging

PU foam is widely used to protect electronic devices and components from physical shock, vibration, and even electrostatic discharge. It can be used for items like laptops, circuit boards, sensors and so on.

Medical and laboratory equipment

For sensitive medical devices such as diagnostic tools, surgical instruments, and lab analyzers, PU foam offers sterile-friendly, non-abrasive protection. Its dimensional stability ensures that packed items arrives safely and undamaged.

Fragile consumer goods

Things like glass, ceramics, and other breakable products can benefit from PU foam’s soft structure and shock-absorbing capacity to prevent the risk of chipping, cracking, or shattering.

Heavy-duty industrial components

PU foam is also suitable for packaging large or heavy items such as automotive parts, machinery components, and precision molds. It protects against sudden impacts during loading, shipping, or storage, especially in rough handling conditions.

Luxury goods

Watches, perfumes, and other high-end items are placed in PU foam inserts to look neat and stay protected inside their boxes.

Temperature-sensitive goods

Some polyurethane foams are engineered with thermal insulation properties, making them ideal for packaging pharmaceuticals, biotech kits, or perishable items that require stable temperature during transit.

Best source for polyurethane packaging foam materials

As a polyurethane system house and a leader in polyurethane raw materials, Imen Polymer Chemie delivers tailored solutions for manufacturers producing unique fragile or sharp-edged items. We understand that every packaging application requires precise technical performance, ease of processing, and regulatory compliance. That’s why our PU systems are designed to meet the requirements of your production line.

If you’re facing challenges in developing high-performance protective packaging, or looking for a better solution to safeguard your products, our expert team is here to help. At Imen Polymer Chemie, we not only supply high-quality polyurethane foam systems tailored for packaging, but also provide complete technical consultation, training, and support. We ensure you get the best performance and maximum value from your packaging process.

With Imen Polymer Chemie, you gain access to

- A range of polyol blends and isocyanate options suited for packaging applications

- Customized formulations for targeted foam density, rebound, and resilience

- Technical consultation and R&D support for new product development

- Reliable logistics and export services to support global customers

Conclusion

Today, packaging does much more than just hold a product; it protects it, improves the customer experience, and even strengthens your brand. Polyurethane foam offers an ideal combination of protection, flexibility, and performance. Whether you’re shipping delicate electronics or luxury items, PU foam helps ensure products arrive safely and look great when unboxed.

When you choose Imen Polymer Chemie as your PU raw material partner, you’re choosing quality, reliability, and expert support. We supply high-performance materials designed specifically for packaging foam, and we work closely with you to get the best results from technical advice to training and process optimization. Partner with a polyurethane system house that brings innovation, reliability, and global expertise to every package you produce. Our packaging foam raw materials are formulated to meet demanding specifications and deliver results that exceed expectations.