Shoe insole foam

Flexible foam

Polyurethane foams are considered the most effective and efficient materials for producing insoles in the footwear industry because they can effectively alleviate pain from prolonged standing. These insoles prevent pressure buildup in specific areas and can even correct and adjust improper body posture. Furthermore, polyurethane insoles maintain their durability over time and exhibit better resistance to compression set compared to other foams with similar density. Shock absorption and dimensional stability are also among the most important features of polyurethane insoles.

Related Products

Imen Polymer Chemie

Some of our latest

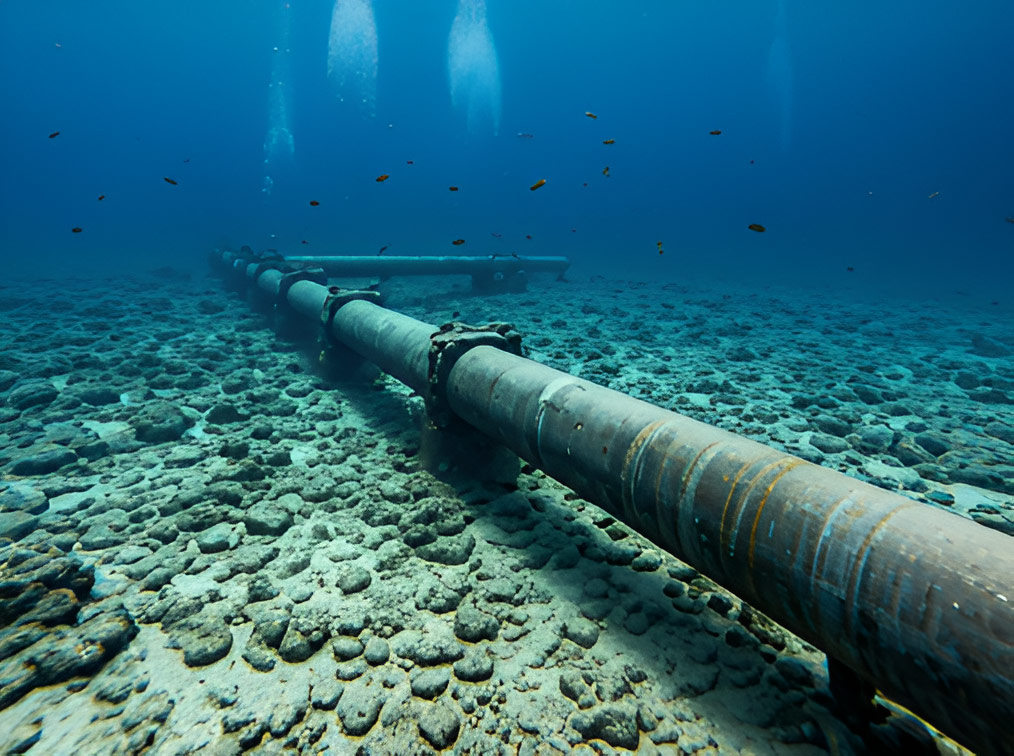

Subsea pipeline insulation

Optimizing electricity consumption in refrigerators with polyurethane insulation

After-sales services

We never leave you

on your own afterwards either

Complete guide to shoe insole foam

Comfort and support are important factors in footwear industry that influence our daily experience. In fact, shoe insoles play a vital role in providing cushioning, shock absorption, and overall foot support. Among various materials used for insoles, foam has become increasingly popular due to its adaptability and comfort. In this article we will talk about the world of shoe insole foam, focusing on different types and advantages, and discuss why polyurethane foam is considered the best choice. We also highlight how to purchase high-quality polyurethane raw materials for shoe insoles from Iran through Imen Polymer Chemie.

What is shoe insole foam?

Shoe insole foam refers to the cushioned layer inside a shoe designed to provide comfort, support, and protection for the foot. This foam acts as a shock absorber and reduces the impact during walking or running, overall enhancing overall foot stability. Foam insoles are produced from various polymeric materials, each of them offers different degrees of softness, durability, and flexibility.

Actually, foam insoles have made a big difference in footwear by allowing manufacturers to customize cushioning properties based on user needs. They improve ergonomics, reduce fatigue, and help in preventing foot-related problems. There are various foam materials out there so, the right choice directly influences the insole’s performance and longevity, making material selection critical for shoe manufacturers.

Types of shoe insoles and their advantages and disadvantages

Each shoe insoles are suited for different purposes and foot conditions. In the following the most common types are mentioned.

Polyurethane insoles:

These are known for their excellent cushioning, durability, and flexibility. Polyurethane foam offers a perfect balance of softness and support, making it suitable for everyday footwear as well as athletic shoes.

Latex insoles:

These insoles are mainly made from synthetic PU latex material, providing good elasticity and breathability. They conform well to foot shape but they are too soft and cannot be used alone (another supporting layer is needed).

Silicone gel insoles:

These insoles use gel particles within a silicone base to provide superior shock absorption and pressure distribution. These are ideal for reducing pain from plantar fasciitis and other foot conditions, gel insoles are often thicker and trap heat.

Leather insoles:

Leather insoles offer natural breathability and moisture control. They provide moderate cushioning but are more focused on durability and foot temperature regulation rather than shock absorption.

As a result, each type has its benefits, but the choice depends on the specific needs such as activity level, foot shape, and desired comfort level. Understanding these differences helps consumers and manufacturers select the best material for their applications.

Polyurethane shoe insoles

Polyurethane (PU) shoe insoles are among the most popular and versatile insoles in the market. PU foam is a polymeric material produced by reacting polyols and isocyanates, resulting in a highly customizable foam with varied densities and hardness levels. PU insoles has several advantages including:

- Exceptional cushioning and energy return, which reduces foot fatigue during prolonged use.

- Durable and resistant to wear and tear, making them ideal for both casual and performance footwear.

- Possibility to be formulated with varying firmness to target different foot arch types and pressure points.

The versatility of polyurethane makes it a favorite among shoe manufacturers who want a balance between comfort, durability, and cost-effectiveness.

Latex shoe insoles

Synthetic latex insoles produced from PU materials are popular for their elasticity and comfort. They mold easily to the contours of the foot, providing a comfortable fit and moderate support.

The natural breathability of latex helps in moisture control, which is beneficial for foot hygiene. PU latex insoles are durable specially when subjected to continuous pressure or moisture exposure. Additionally, some individuals may have allergies to natural latex, so these latex foams are the best option.

Silicone gel shoe insoles

Silicone gel insoles are noticeable due to their superior shock-absorbing qualities. The gel within the silicone distributes impact forces evenly on the foot, this reduces localized pressure that causes pain.

These insoles are particularly recommended for medical conditions such as plantar fasciitis, metatarsalgia, and heel spurs. However, silicone gel insoles tend to be bulkier, which might affect the shoe’s fit and flexibility. They are generally less breathable compared to foam-based insoles.

Silicone gel insoles are more specialized, offering targeted relief rather than all-day comfort for general footwear. Also, it has to be mentioned that they may lose effectiveness over time, requiring replacement

Leather insoles

Leather insoles have been used traditionally for their durability and natural moisture-wicking properties. They provide a firm base inside the shoe and keep foot temperature by allowing ventilation.

Although leather insoles offer the least cushioning properties compared to foam or gel, they are good at enhancing shoe structure and longevity. Their rigidity limits those applications needing extra shock absorption, but they are often combined with foam layers for improved comfort.

Leather insoles remain a preferred choice for formal shoes and boots where durability and moisture control are prioritized.

Why is polyurethane considered the best material for making shoe insoles?

Polyurethane is considered the best material for shoe insoles due to its unique combination of properties. This polymer offers superior cushioning without losing its durability, adapting well to different foot shapes and pressure needs.

PU foam’s cellular structure provides excellent shock absorption and energy return, reducing stress on joints and muscles. It also resists compression set, meaning the foam maintains its shape and support over time, unlike some other materials that flatten with repeated use.

Furthermore, polyurethane foam can be produced in a wide range of densities and hardness levels, allowing customization for sports shoes, casual wear, and orthopedic insoles. Its unique characteristics and cost-effectiveness make it an ideal choice for mass production and high-quality footwear.

Comparison of different types of polyurethane shoe insoles

Polyurethane insoles come in various formulations, each of them can be tailored for specific applications. Some common categories include the following:

Memory foam PU insoles:

These mold to the foot’s contours, offering personalized comfort and pressure relief. That’s ideal for people who require cushioning for long hours of standing or walking.

Cold cure PU insoles:

Known for their resilience and durability, cold cure foam insoles maintain comfort in warm climates and active use. They provide consistent support without excessive softness.

Latex PU insoles:

Offering high elasticity and breathability. It is highly favored in bedding, furniture, toys, and shoe insoles.

Each type of PU insole has their own pros and cons so they are used in different conditions. However, they are all benefit from polyurethane’s inherent qualities of shock absorption, durability, and versatility. Also, the ability to customize PU foams makes them superior to other alternatives.

Purchasing raw materials of polyurethane foam for shoe insoles from Iran

Iran has emerged as a significant supplier of high-quality polyurethane raw materials for the footwear industry. Companies like Imen Polymer Chemie specialize in producing advanced polyurethane polyols and isocyanates, the essential components for manufacturing durable and comfortable PU shoe insoles.

Purchasing polyurethane raw materials from Iran offers several advantages:

- Access to competitively priced, high-quality raw materials manufactured under strict quality control.

- Technical support and customization options to tailor foam properties according to specific product needs.

- Reliable export services ensuring timely delivery to global manufacturers.

We at Imen Polymer Chemie, with our extensive expertise and modern production facilities, are a trusted partner for international footwear producers seeking polyurethane materials that meet global standards. Collaborating with suppliers like us ensures access to innovative materials that enhance product performance and customer satisfaction.

Conclusion

In summary, shoe insole foam plays a vital role in enhancing footwear comfort, support, and durability. Among various materials, polyurethane has gained the most attention and popularity due to its exceptional properties. Whether it is memory foam, cold cure foam, or polyurethane latex foam, these insoles provide tailored solutions for different foot needs and activities. While other materials have their own benefits, polyurethane’s balance of comfort, durability, and customization makes it the preferred material for shoe insoles worldwide. For manufacturers seeking high-quality raw materials, sourcing polyurethane foam components from reliable suppliers like Imen Polymer Chemie in Iran ensures access to advanced, competitively priced products and technical support.