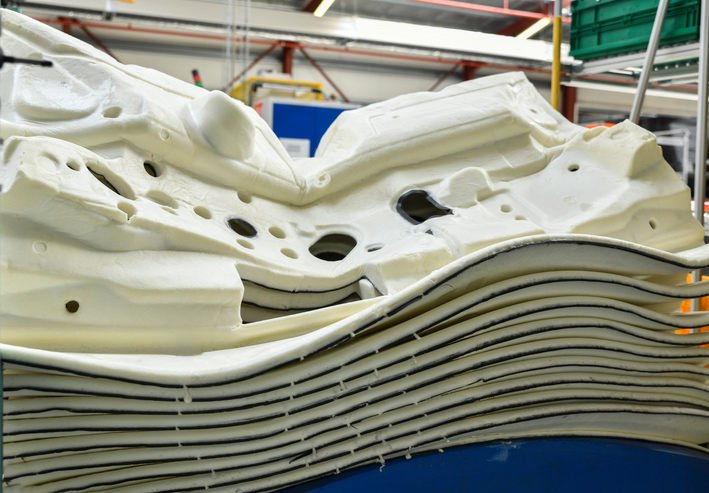

Car sound deadening foam

Flexible foam

One of the advantages of polyurethane foam in the automotive industry is its sound-absorbing properties. Vehicles produce various noises that can be disturbing to passengers. These sounds can be categorized into two types: airborne noises from outside the vehicle or structural noise generated by the vehicle’s internal structures. Since these sounds range between 500 to 2500 Hz, which is a frequency range sensitive to human hearing, they can be particularly bothersome.

Polyurethane foam can absorb sound waves and reduce the noise level inside the car cabin. This foam can be used in various parts of the vehicle, including doors, the roof, and the floor, significantly reducing unwanted noises.

Product codes

Related industries

Some of

Related Products

Imen Polymer Chemie

Some of our latest

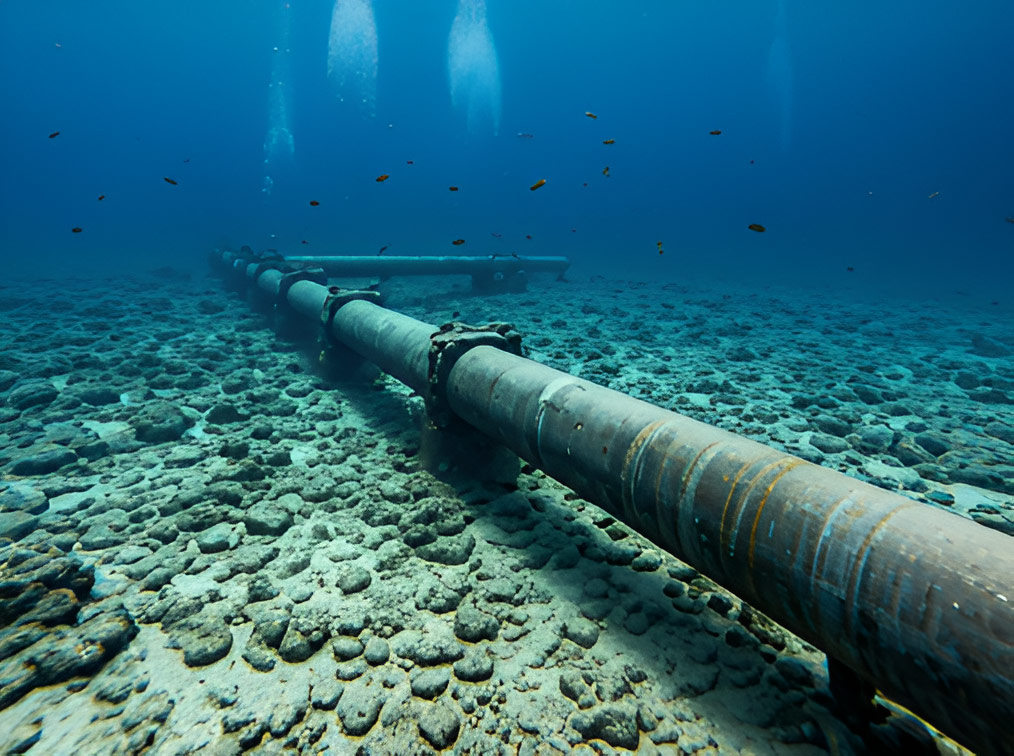

Subsea pipeline insulation

Optimizing electricity consumption in refrigerators with polyurethane insulation

After-sales services

We never leave you

on your own afterwards either

Car sound insulation with polyurethane foam

Car sound insulation is one of the most important factors in achieving a quiet, comfortable, and enjoyable driving experience. Generated noise from the engine, tires, road vibrations, and external environment can significantly affect the performance and convenience of the vehicle. Therefore, using effective soundproofing solutions is of great importance to reduce unwanted noise and improve the overall quality of the car interior. Among the various materials available for sound insulation, polyurethane foam has become one of the most trusted and widely used solutions worldwide.

Polyurethane foam offers excellent acoustic properties, flexibility in application, and long-term durability, making it an ideal choice for both automobile manufacturers and aftermarket solutions. Whether applied in the body panels, roof, doors, or flooring, this material provides strong sound absorption and helps create a calmer driving atmosphere. In the following article, we will discuss the use of polyurethane as a sound-deadening material in automotive applications, mentioning its advantages, performance, and role in creating a quieter driving experience.

Why choose polyurethane foam for car soundproofing?

Polyurethane foam is the best solution for soundproofing cars; it has several advantages including:

1. Superior sound absorption

Sound insulation polyurethane foam with a high open-cell structure allows it to absorb a wide range of sound frequencies effectively. This property helps in reducing engine noise, vibrations from the road, and even wind noise at higher speeds. Unlike some other materials that only block sound, polyurethane foam works by absorbing and dissipating acoustic energy, resulting in a much quieter cabin environment.

Moreover, polyurethane foam can be customized in different densities and formulations to meet specific automotive requirements. Whether the goal is to reduce low-frequency vibrations or high-pitched mechanical sounds, the versatility of polyurethane ensures that it provides effective soundproofing in the entire spectrum.

2. Seamless application

Polyurethane foam is highly adaptable and can be applied to various parts of the car interior and structure. It can be sprayed onto large surfaces or injected into molds and placed within doors and panels. This flexibility makes it easy for car manufacturers and workshops to integrate polyurethane into existing designs without major modifications.

The lightweight nature of polyurethane foam also ensures that it does not add significant weight to the vehicle. This is a major advantage since soundproofing materials should not compromise the car’s fuel efficiency or overall performance. Polyurethane provides a seamless balance between sound insulation and practicality.

3. Durability and longevity

Automotive environments are often exposed to extreme temperatures, moisture, vibrations, and continuous wear. Polyurethane foam is so popular because of its excellent resistance to such challenging conditions. Unlike some traditional materials that degrade or lose their performance over time, polyurethane keeps its structure and acoustic properties for many years.

This durability ensures that car owners and manufacturers enjoy a long-lasting soundproofing solution without frequent replacements or repairs. By investing in polyurethane-based sound insulation, users gain both cost-efficiency and reliability over the lifespan of the vehicle.

Benefits of using polyurethane foam for car sound insulation

The benefits of polyurethane foam are not limited only to noise reduction. One of the key advantages is the improvement of overall driving comfort. A quieter interior allows drivers and passengers to focus better, communicate easily, and enjoy entertainment systems without external interference. This directly increases the feeling of satisfaction inside the car.

Another important benefit is the way polyurethane foam enhances the in-car experience by supporting clearer conversations and better use of entertainment systems. When background noise is reduced, music, navigation instructions, and even hands-free calls become much easier to hear. This means polyurethane foam not only has sound-dampening properties but also improves how the car interior feels and works.

Applications of polyurethane foam for car sound insulation

Polyurethane foam can be applied in multiple areas of a car to maximize soundproofing performance. It is often used in the doors, dashboards, trunk areas, under the car’s hood (bonnet), and under the floor mats. These strategic applications help reduce vibrations and block noise from entering the cabin.

In addition, polyurethane foam is applied inside structural cavities, such as body panels and engine compartments. By filling these spaces, the foam prevents sound waves transmission (block noise) and improve overall sound quality.

Beyond these standard uses, polyurethane foam is also applied in roof linings and around wheel arches, where it plays a key role in minimizing wind noise and road noise generated by tires. These are common sources of disturbance during high-speed driving, and polyurethane’s ability to absorb and dampen those sounds makes the driving experience smoother and less fatiguing.

Another important application is in sealing gaps and joints within the vehicle’s frame. Even small openings can become channels for noise to enter the cabin. By using polyurethane foam to fill these gaps, manufacturers ensure a tighter structure that prevents sound leakage while also offering added reinforcement against dust and moisture. This multifunctional role of polyurethane makes it a versatile material that has become so popular in automotive industry.

Comparison: Polyurethane foam vs. other car sound insulation materials

For car soundproofing, manufacturers often choose from bitumen sheets, rubber mats, fiberglass, or modern composite assemblies. Bitumen and rubber are good at damping structure-borne vibration and low-frequency noise but they often add extra weight to the vehicle and may not deliver the same level of acoustic absorption as polyurethane.

Fiberglass insulation is another alternative for mid and high frequencies, but comes with limitations such as reduced durability, potential health risks during installation, and poor resistance to moisture.

Polyurethane (PU) foam, on the other hand, combines lightweight construction, excellent sound absorption, resistance to harsh conditions, and long service life, making it a more reliable choice for automotive applications.

Also, many automotive solutions combine materials into multi-layer composites so each layer does what it does best for example, a thin damping layer for vibration control, a textile or nonwoven facing for durability, and an absorptive core for broad-band sound reduction.

In multi-layer composites, PU foam helps reduce cabin noise without the weight penalty of heavy sheets, and it can be tailored for density, cell structure and environmental resistance to suit different vehicle areas.

How to apply polyurethane foam for car sound insulation?

The application of polyurethane foam depends on the specific design and requirements of the vehicle. In industrial prodaauction, polyurethane foam can be injected into cavities during the assembly process or sprayed onto larger areas for comprehensive coverage. These methods let manufacturers add sound insulation in a smooth and efficient way, without slowing down production.

For aftermarket applications, polyurethane sheets or pre-formed panels can be placed inside doors, roofs, or floors. Professional workshops often use polyurethane foam in combination with other soundproofing methods to achieve optimal results. Correct installation is critical to ensure maximum performance, so expert consultation and proper material selection are so important.

Buying polyurethane foam materials for car insulation from Iran

Iran is becoming a key center for polyurethane raw material production, and Imen Polymer Chemie is one of the leading companies in this industry. As a polyurethane system house, Imen Polymer Chemie offers high-quality raw materials specially developed for automotive sound insulation. Our products are made to meet international standards, delivering efficiency, durability, and competitive pricing for global markets.

By sourcing polyurethane materials directly from Iran, buyers benefit from advanced formulations, reliable supply chains, and full technical support. Imen Polymer Chemie goes beyond supplying raw materials by providing expert consultation to help clients achieve the best soundproofing results in their automotive projects.

Imen Polymer Chemie supplies polyurethane raw materials designed for these NVH and composite applications and offers technical support to help you choose and adjust the right formulation for performance, durability and manufacturability.

Conclusion

Polyurethane foam is widely known as one of the best materials for car sound insulation. It absorbs noise effectively, is easy to apply, and stays durable over time, making it a top choice for both automakers and aftermarket users. In addition to reducing noise, polyurethane foam also improves thermal insulation, keeps vehicles lightweight, and lowers overall costs, helping create a better driving experience.

For companies that want to improve vehicle quality and meet customer needs, using dependable polyurethane raw materials is key. With advanced production facilities, Imen Polymer Chemie supplies high-quality polyurethane materials designed for automotive soundproofing. Along with reliable products, we provide technical support and competitive supply options. By choosing polyurethane foam from Iran through Imen Polymer Chemie, businesses gain excellent results and long-term value in the automotive industry.