Latex foam

soft (flexible) foam

Polyurethane latex-like foam has an open-cell structure, offering excellent flexibility and comfort. It is highly popular due to its high elasticity and long lifespan. Latex-like flexible polyurethane foam provides good ventilation and helps distribute body weight evenly. Additionally, this foam acts as a hypoallergenic and antibacterial material, making it especially suitable for use in mattresses, pillows, furniture, and orthopedic products.

Product codes

Related industries

Some advantages of polyurethane latex foam (latex-like foam):

- High flexibility

- Excellent durability

- Comfort

- Moisture resistance

- High breathability

- Allergy resistance

- Antibacterial properties

- Hypoallergenic

- Vibration and sound absorption

- Resistant to abrasion and tearing

Imen Polymer Chemie

Some of our latest

What are aliphatic isocyanates?

Polyurethane display refrigerator foam

After-sales services

We never leave you

on your own afterwards either

What is latex foam?

Latex foam is a type of flexible foam made from natural or synthetic latex, known for its unique properties and applications in various industries. Before World War II, almost all latex used in production was natural. During the war, latex was in short supply, leading to a search for synthetic alternatives. Since then, various types of synthetic latex have been created and used. In the following content we are going to explore it more.

Types of latex foam

Natural Latex Foam

Natural latex is extracted from the sap of the rubber tree and, after processing, becomes an elastic and durable material. This type of latex foam is ideal for people sensitive to chemicals due to its antibacterial, antifungal, and hypoallergenic properties. Moreover, natural latex has an open cell structure and high breathability, preventing excessive moisture and heat buildup, thus providing a cool and dry environment.

Synthetic Latex Foam

Scientists initially tried to create a material similar to natural latex using poly-cis-isoprene plastic, but it had lower quality and was abandoned. Instead, they developed latex based on a synthetic polymer that behaves similarly. This latex is usually cheaper than natural latex and can be produced on a larger scale with varied properties. Synthetic latex foams are generally more durable and have a longer lifespan but may have fewer hypoallergenic qualities than natural latex.

Synthetic latex, which mimics the appearance of natural latex, can be produced in labs using petroleum-based chemical components. These synthetic latex foams can closely resemble natural latex and can be vulcanized similarly to produce various types of latex foam for different applications.

Differences between natural and synthetic latex foam

Natural and synthetic latex share similar features, but synthetic latex is generally stronger than natural latex. Natural latex is more flexible (softer) but tears more easily. Both types of latex offer benefits for different reasons.

Latex also comes in two subtypes: Talalay and Dunlop, each with its own characteristics. The main difference between the two is that Talalay is known for being lighter and more porous, while Dunlop is denser and therefore heavier. Talalay latex is often made from a mix of natural and synthetic latex, whereas Dunlop is purely natural. Both materials are ideal for new mattresses, but Dunlop tends to be superior because Talalay latex made entirely from natural latex is less durable than its blended counterpart.

The difference in quality among latex mattresses comes from the latex core production process. Manufacturers often use a blend of natural and synthetic latex to achieve better overall properties and keep costs down. Since natural latex is very soft and elastic, while synthetic latex adds firmness, it’s easy to see how a combination of the two can create a useful material.

Properties and advantages of polyurethane latex foam

Polyurethane latex foams (latex-like foams), which combine the properties of latex and polyurethane, offer multiple advantages:

High Flexibility

These foams are highly flexible and comfortable, making them ideal for bedding and furniture products.

Proper Support

Polyurethane latex foam effectively distributes body pressure, preventing pressure points.

Long Life

These foams are highly durable, giving them a longer lifespan than other foams.

Breathability

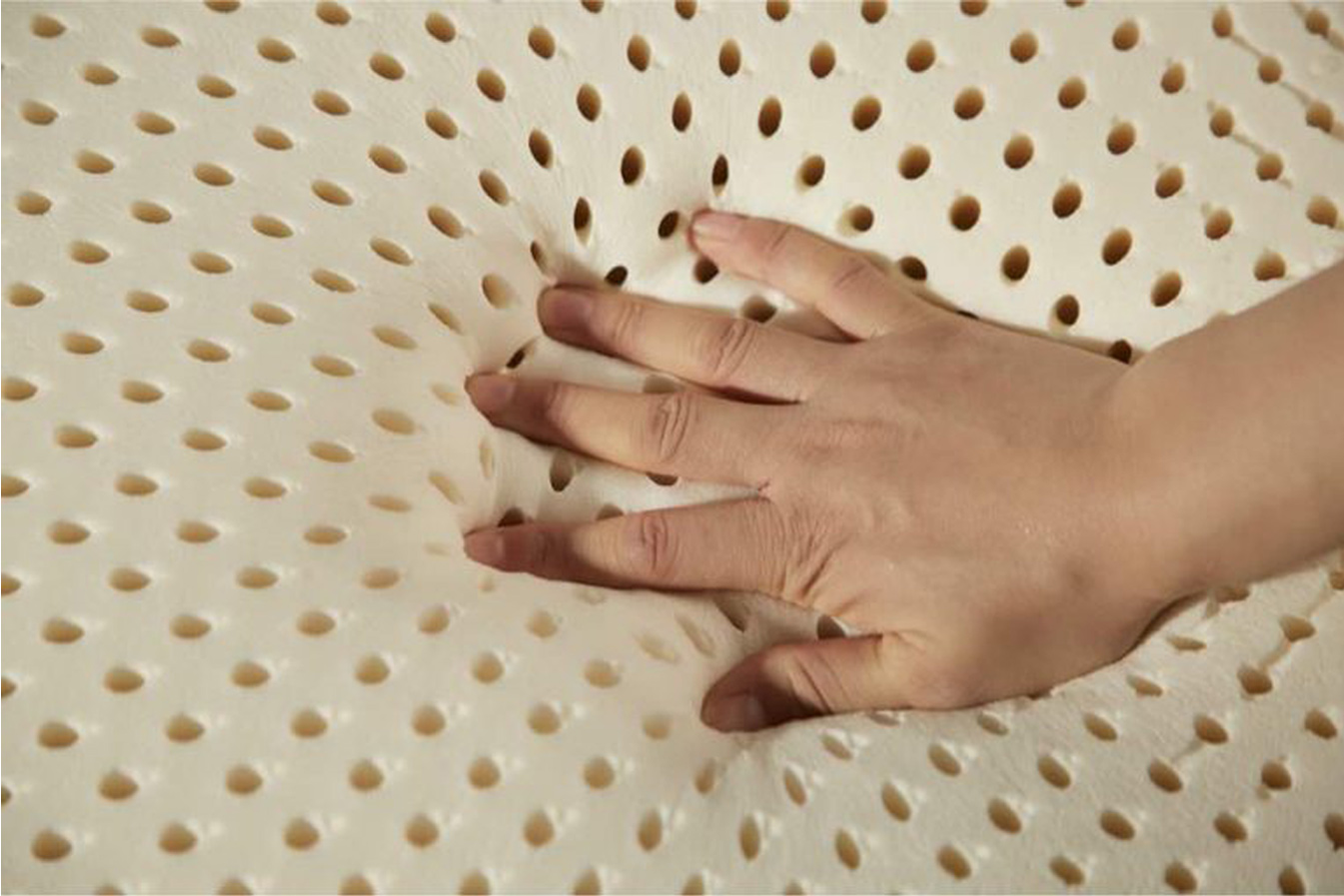

The open-cell structure allows for proper airflow, preventing heat and moisture buildup in mattresses and furniture.

Hypoallergenic and Antibacterial

These properties are particularly important for people with allergies.

Applications of polyurethane latex foam

Polyurethane latex foam is used in a wide range of products and industries, including:

Mattresses and bedding

One of the most common applications is in the creation of orthopedic and comfort mattresses. These mattresses are perfect for long-term use, offering a comfortable sleep experience thanks to their breathability and body support.

Furniture

These foams are used in comfortable and office furniture due to their flexibility and high durability.

Orthopedic products

Various support pillows and cushions designed to support the body in specific positions can be made from polyurethane latex foam.

Automotive industry

These foams are also used in car seats and interior components due to their comfort and resistance.

Advantages and disadvantages of latex mattresses

Among the applications of latex foam, mattresses and pillows (bedding products) are the most widely consumed. Therefore, the advantages and disadvantages of latex mattresses are listed below:

Advantages:

Excellent comfort and support

Due to their elastic and open structure, latex mattresses provide excellent comfort and body support, reducing pressure points.

Good breathability

These mattresses ensure a cool and dry sleep environment due to good ventilation.

Long lifespan

The durability and resilience of latex mattresses give them a long lifespan.

Disadvantages:

High cost

Latex mattresses are generally more expensive than other types of mattresses.

Allergy to natural latex

Some people may be allergic to natural latex, in which case synthetic polyurethane latex is recommended.

Hypoallergenic and antibacterial

These products are ideal for people with allergies and sensitive skin.

Difference between latex mattresses and memory foam

Latex mattresses and memory foam mattresses share some similarities due to their open-cell structure, but they also have distinct differences, which are highlighted below.

Latex Mattress:

Natural and Synthetic Materials

Latex mattresses can be made from either natural or synthetic materials, each offering unique characteristics.

High Flexibility

These mattresses quickly regain their original shape and experience less permanent deformation. They are recognized for their immediate response or bounce-back, thanks to the foam’s inherent springiness.

Breathability

Latex mattresses provide better ventilation, helping to prevent heat and moisture buildup.

Balanced Support

These mattresses offer balanced support for the body, distributing pressure evenly.

Motion Transfer

They distribute applied stress across the surface without reducing it.

Memory Foam Mattress

Less Flexibility

Memory foam mattresses take longer to return to their original shape and tend to have more permanent deformation.

Lower Breathability

Their dense structure means memory foam mattresses retain more heat and can become warmer.

Pressure Point Support

These mattresses contour to the body, effectively reducing pressure and creating a sensation of immersion.

Motion Transfer

Memory foams absorb stress and prevent it from transferring to other areas.

Overall, the choice between latex and memory foam mattresses depends on individual needs and preferences, but both options are among the best in the market, and the materials for both are available in Imen Polymer Chemie’s product range.

Purchasing latex foam material from Imen Polymer Chemie

Polyurethane latex foams are widely used in industries such as mattress and furniture production due to their numerous advantages. These foams combine comfort, durability, and proper support, attracting significant attention. The raw materials for producing the foams are available from Imen Polymer Chemie under the code ImPol LX. For more information, please contact the us at 009821-57325.